Square rigid cable dome structure

A cable dome and square technology, which is applied in the field of square rigid cable dome structure, can solve the problems that the structural plane is limited to circular and elliptical, the ridge cable is easy to withdraw from work, and the rigidity outside the plane is insufficient, so as to achieve fewer structural components and avoid displacement changes The effect of sudden increase and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

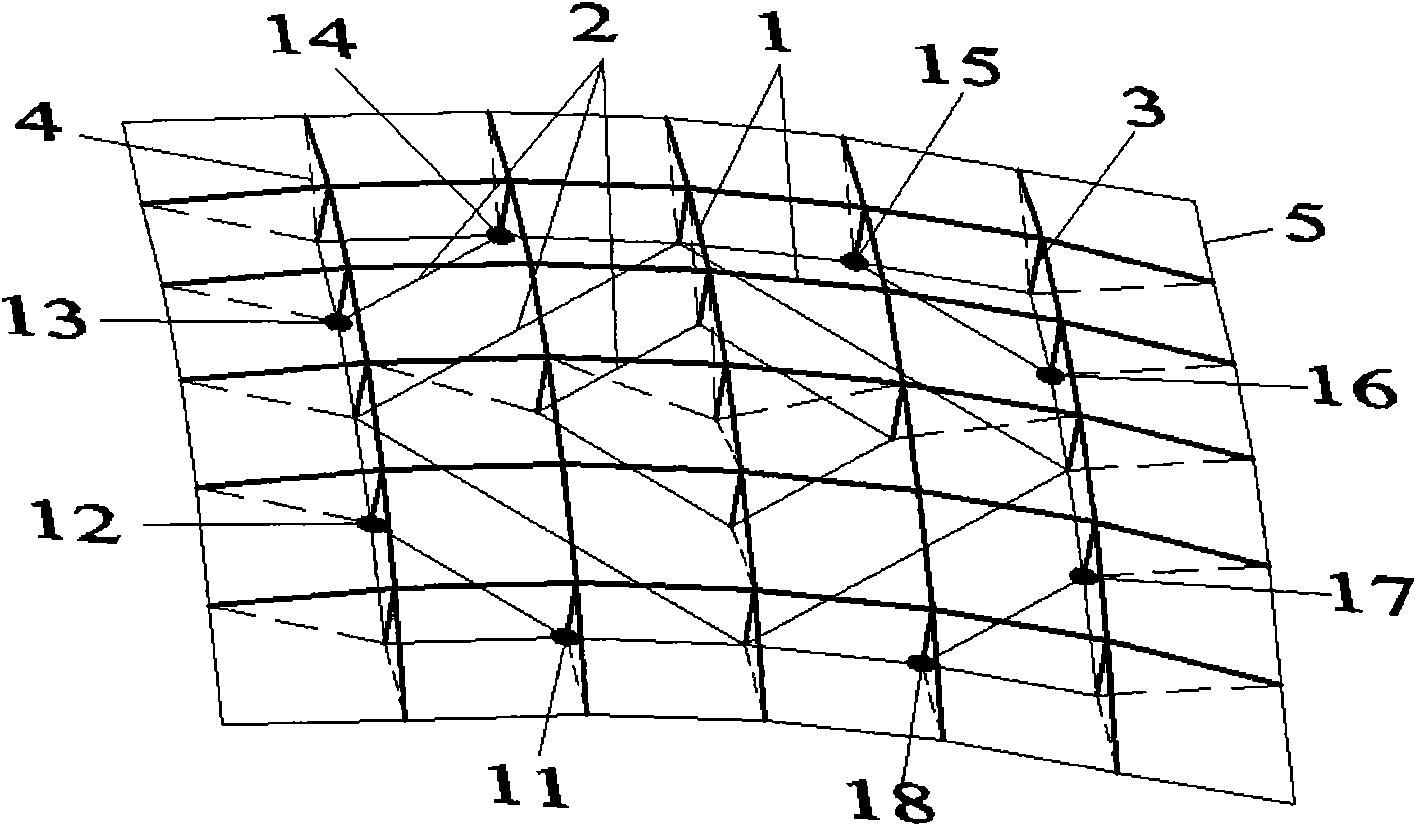

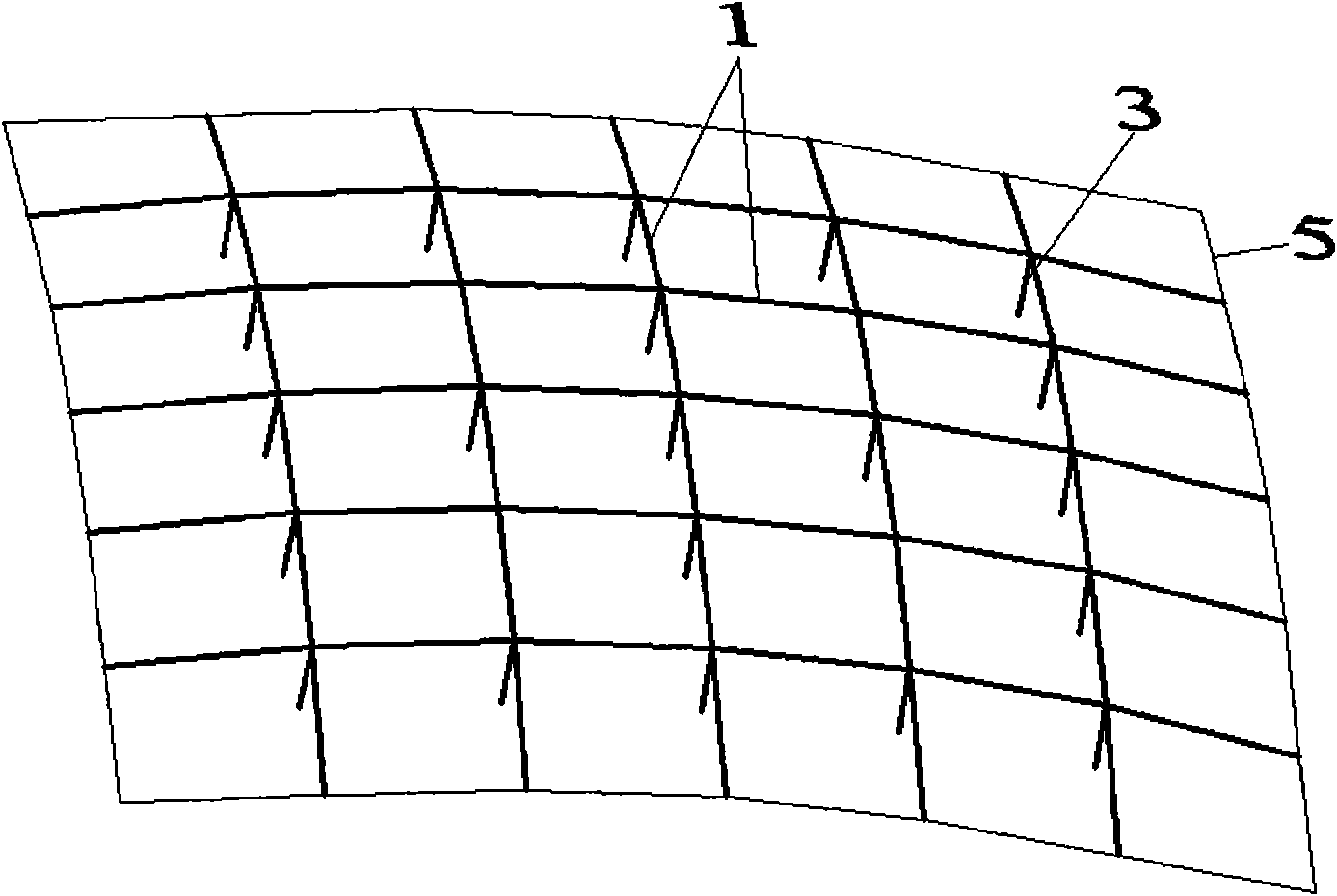

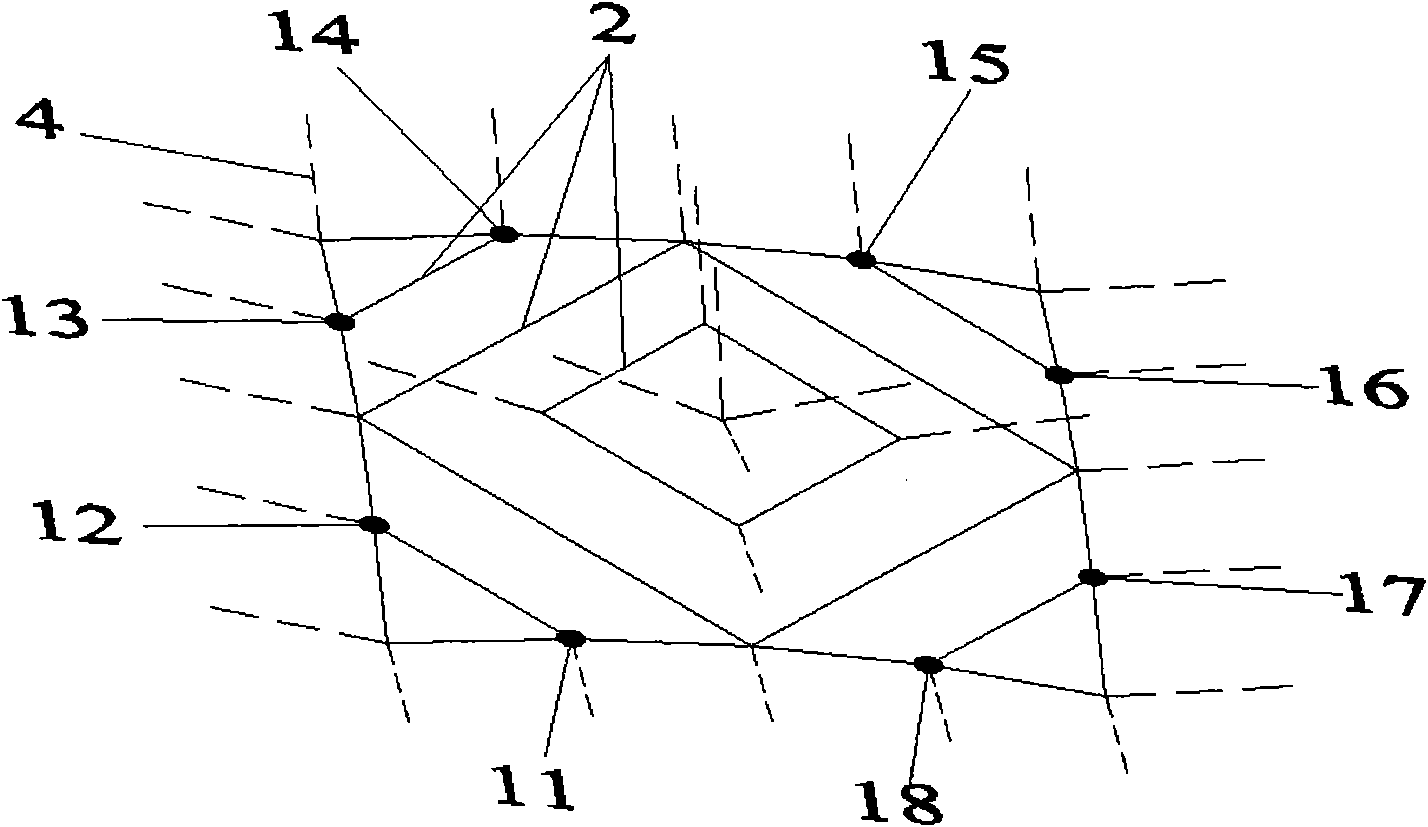

[0021] Such as figure 1 As shown, the rigid members 1 in the square rigid cable dome structure are mutually perpendicular grids, and on an upward convex hyperboloid, edge ring beams 5 are arranged around the grid of the rigid members 1, and the horizontal symmetry axis and the vertical The grid nodes of the rigid member 1 on the axis of symmetry and the grid nodes of the surrounding rigid member 1 are provided with a vertical strut 3 perpendicular to the ground, and the grid of the rigid member 1 on the horizontal axis of symmetry and the vertical axis of symmetry The lower end of the lattice node and its inner adjacent vertical strut 3 is connected with a diagonal cable 4, the node of the edge ring beam 5 and the rigid member 1 is connected with the lower end of its inner adjacent vertical strut 3 with a diagonal cable 4, and the horizontal axis of symmetry and The lower ends of the vertical struts 3 on the vertical axis of symmetry are connected to form a square lower chord ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com