Crystal frequency multiplier

A frequency doubler and crystal technology, applied in the field of lasers, can solve the problems of increasing the loss in the laser and the laser cavity, and the damage of the film layer, and achieve the effect of simplifying the coating process, improving the output power, and reducing the loss in the cavity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

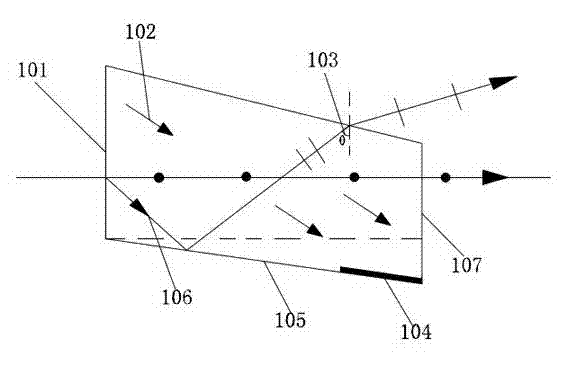

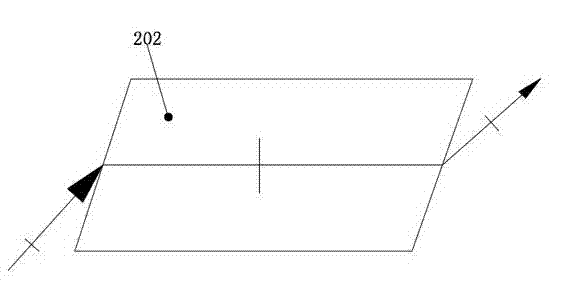

[0019] Such as figure 2 , image 3 As shown in Example 1 of the present invention, the incident fundamental frequency light enters and exits the frequency-doubled crystal at the Brewster angle, and generates frequency-doubled light e light during this process, and the frequency-doubled light walks away and is polished Total reflection occurs on the side of the doubled frequency crystal, and then exits from the side of the crystal opposite to the total reflection surface at Brewster's angle without loss. similar to figure 1 As shown, the reflective surface of the frequency doubled light can be parallel to the optical track of the fundamental frequency light o, or present a certain angle. Since the frequency-doubled light will continue to be generated during the whole process of the base-frequency light passing through the frequency-doubled crystal, in order to avoid the ultraviolet frequency-doubled light generated near the base-frequency light output end as e-light from bei...

Embodiment 2

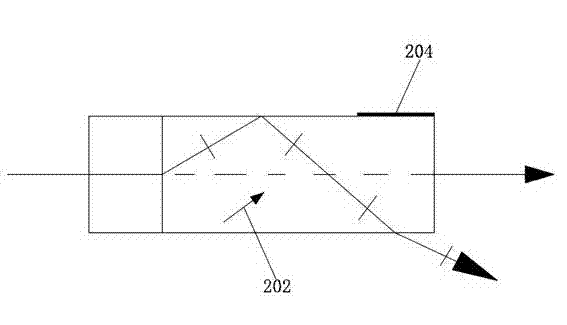

[0021] Such as Figure 4 As shown in Embodiment 2 of the present invention, the incident fundamental frequency light (including o light and e light at the same time) passes through the frequency doubling crystal coated with the fundamental frequency light antireflection film, and in this process generates frequency doubling light e light, the fundamental frequency The e-light λ1 of the light and the generated frequency-doubled light e-light λ2 are totally reflected on the side of the polished frequency-doubled crystal, and then the frequency-doubled light exits from the side of the crystal opposite to the total reflection surface at the Brewster angle without loss. similar to figure 1 As shown, the reflective surface of the frequency doubled light can be parallel to the optical track of the fundamental frequency light o, or present a certain angle. Since the frequency doubled light will continue to be generated during the whole process of the base frequency light passing thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com