Triple shielding flame retardant type single core nuclear power cable

A power cable and flame-retardant technology, applied in the field of power cables used in nuclear power plants, can solve problems such as interference, hidden dangers of system normal operation, and can not solve the problem of electromagnetic shielding of power cables, so as to eliminate the interference of high-order harmonics to the outside world, The effect of reducing the shaft voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

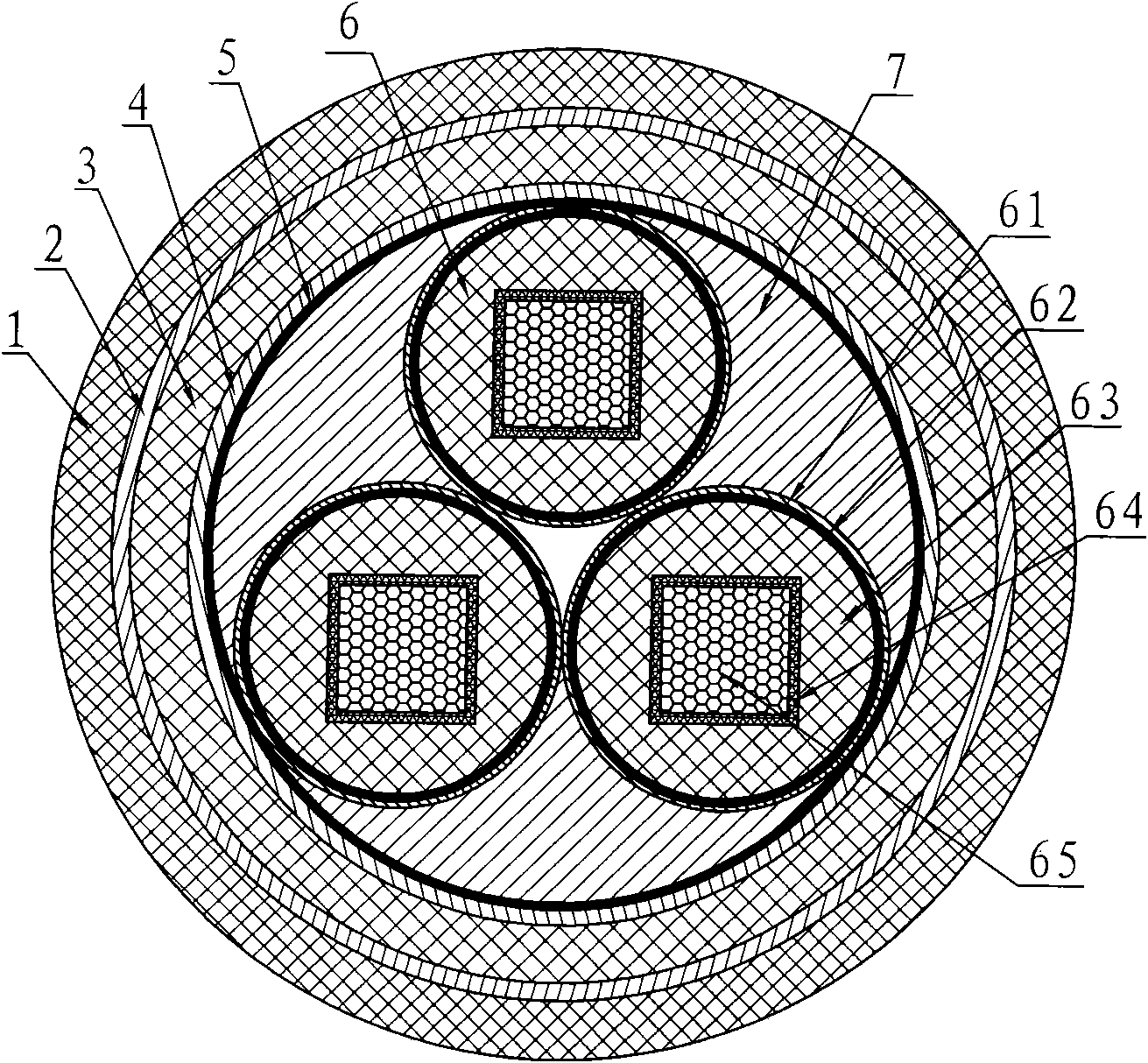

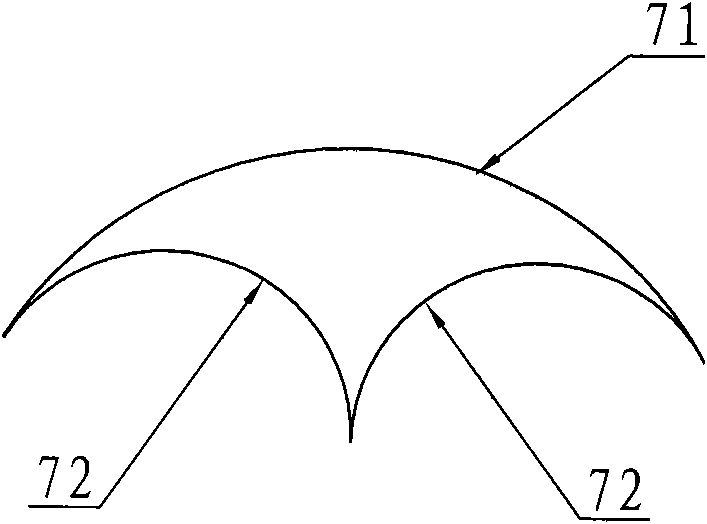

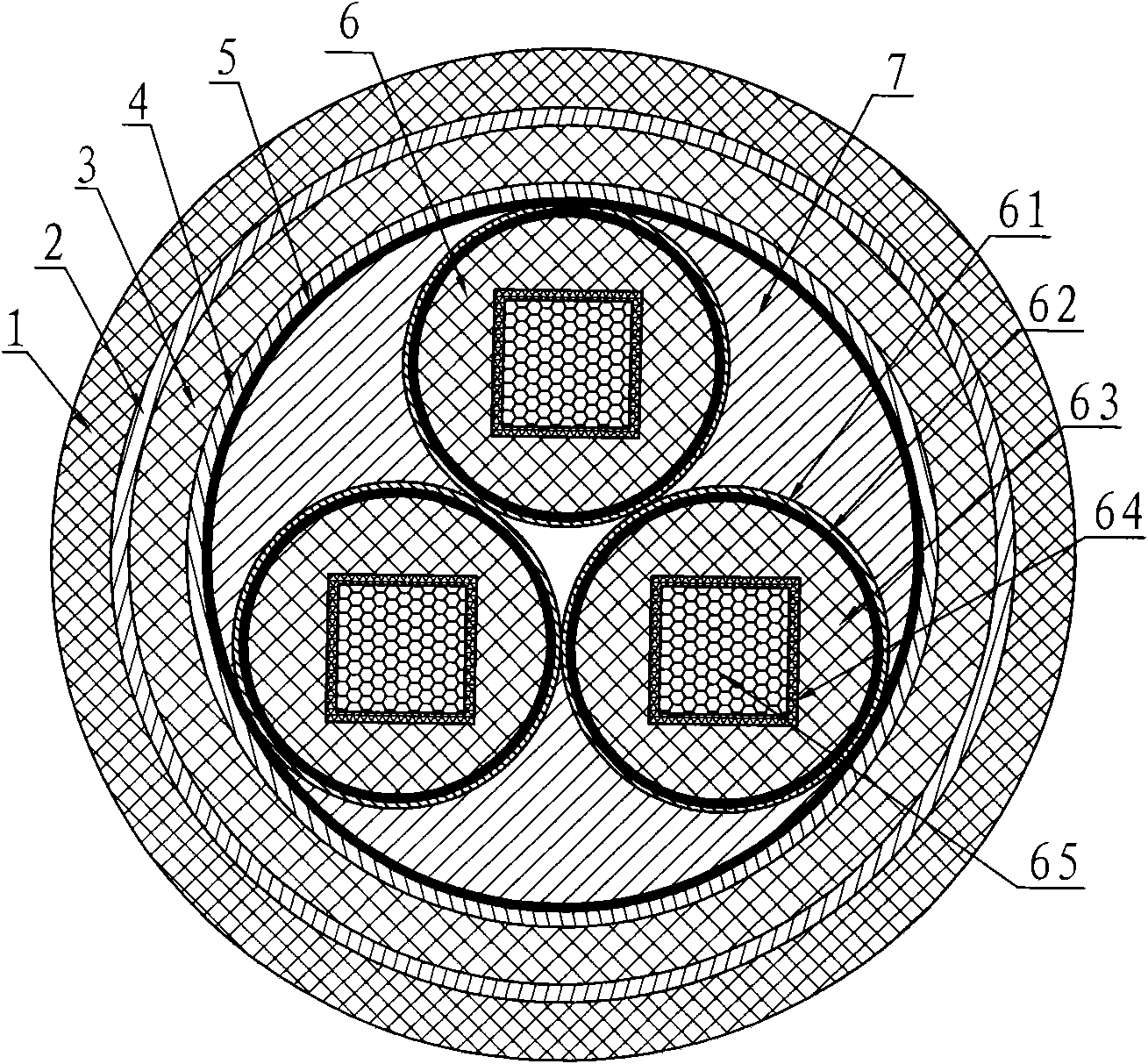

[0017] Described a triple shielding flame retardant single core nuclear power cable, such as figure 1 , figure 2 As shown, it consists of an outer insulating sheath 1, a first shielding layer 2, an inner insulating sheath 3, a second shielding layer 4, a bus insulation mesh tape 5, a sub-wire 6 and a sub-wire filling bead 7, and the sub-wire 6 is composed of a sub-wire Wire shielding layer 61, sub-wire insulation mesh belt 62, sub-wire sheath 63, heat insulation film 64 and conductor core 65 are composed of heat insulation film 64, sub-wire sheath 63, and sub-wire insulation The mesh belt 62 and the sub-wire shielding layer 61, the outer circles of the three sub-wires 6 are in contact with each other, and their centers are arranged in an equilateral triangle, and the three sub-wires fill the bead 7 and are arranged in the space formed by the contact of the three sub-wires 6, so that the three sub-wires 6 and the three sub-wires fill the bead 7 forms a circular cross section,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com