Manufacturing method for slot forming type commutator and products thereof

A manufacturing method and molding technology, which are applied in the manufacture of commutators, rotary current collectors, current collectors, etc., can solve the waste of commutator segment materials, poor insulation performance of commutator segments, and affect the technical performance of commutator products. quality and other issues, to achieve the effect of extending service life, reliable contact strength, and improving technical performance and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

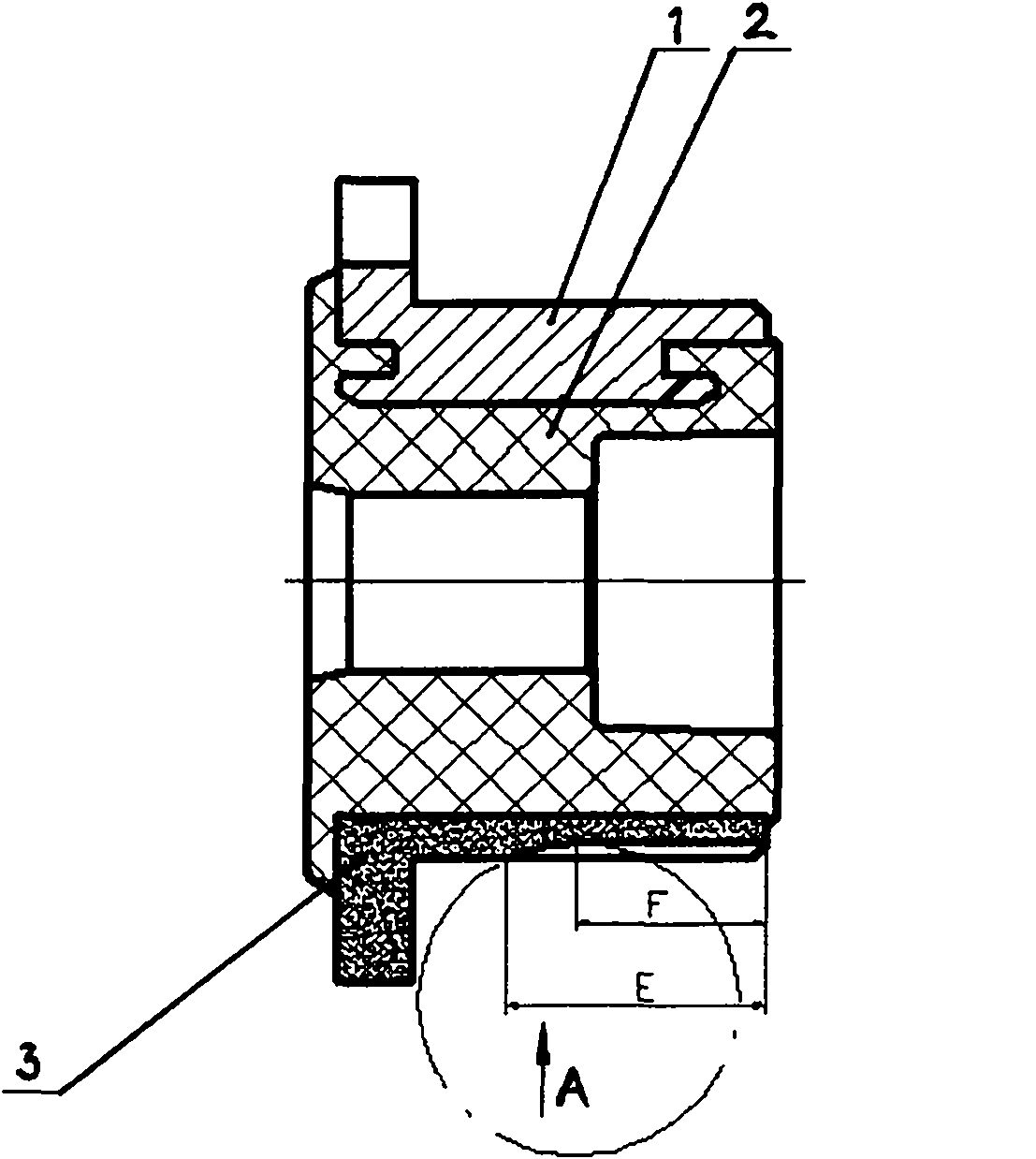

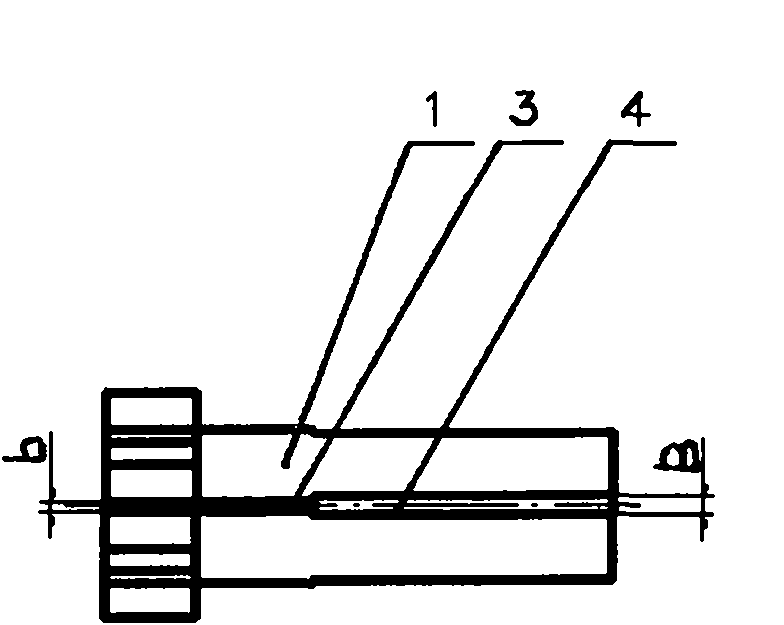

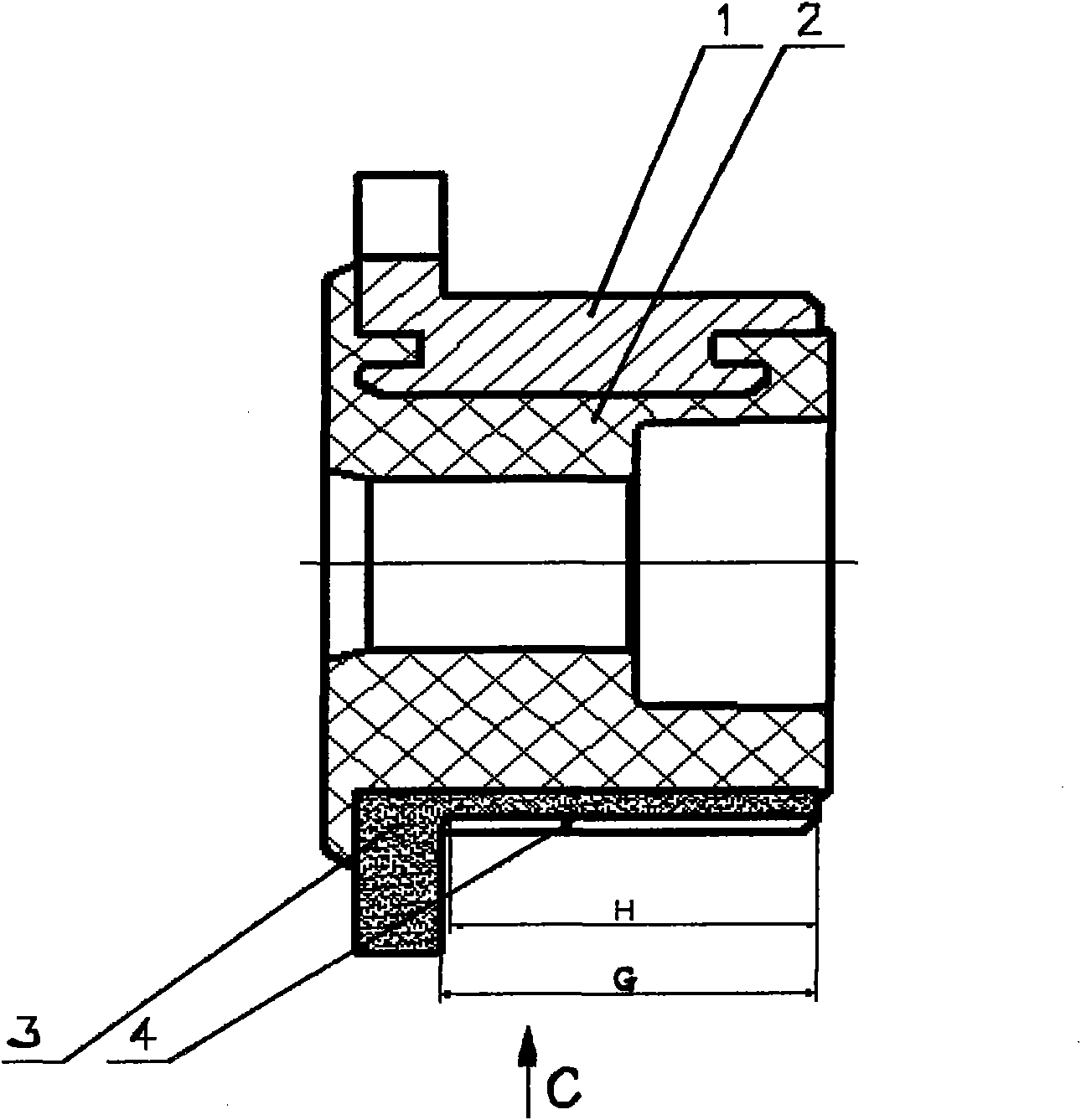

[0012] Reference figure 1 , figure 2 It can be seen that the commutator made by the well-known original technology includes the commutator piece 1, the molding compound 2, the mica piece 3, and the inter-plate groove 4 between the commutator pieces first uses a thinner mica piece 3 (the original width is b) As the width of the insulating layer, after the slot milling process, a wider insulating slot width B is obtained. That is to say, the width of the insulating layer is slightly narrower than the width of the insulating groove (ie b<B), and the body part of the commutator segment is slightly wider than the body part after milling the groove, resulting in the insufficient insulation between the commutator segments. Claim. Set the length of the milling groove as E, and the mating length with the carbon brush as F, then F<E, that is, the mating length with the carbon brush is very short. To match the carbon brushes normally, the total length of the commutator must be increased...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com