Sandpaper with non-slip coating layer

A technology of anti-slip coating and sandpaper sheets, which is applied in the direction of grinding tools, manufacturing tools, abrasives, etc., can solve the problems of tearing of folding lines, failure of sandpaper, weakening of sandpaper, etc., and achieve improved moisture resistance, simple cost, and improved flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

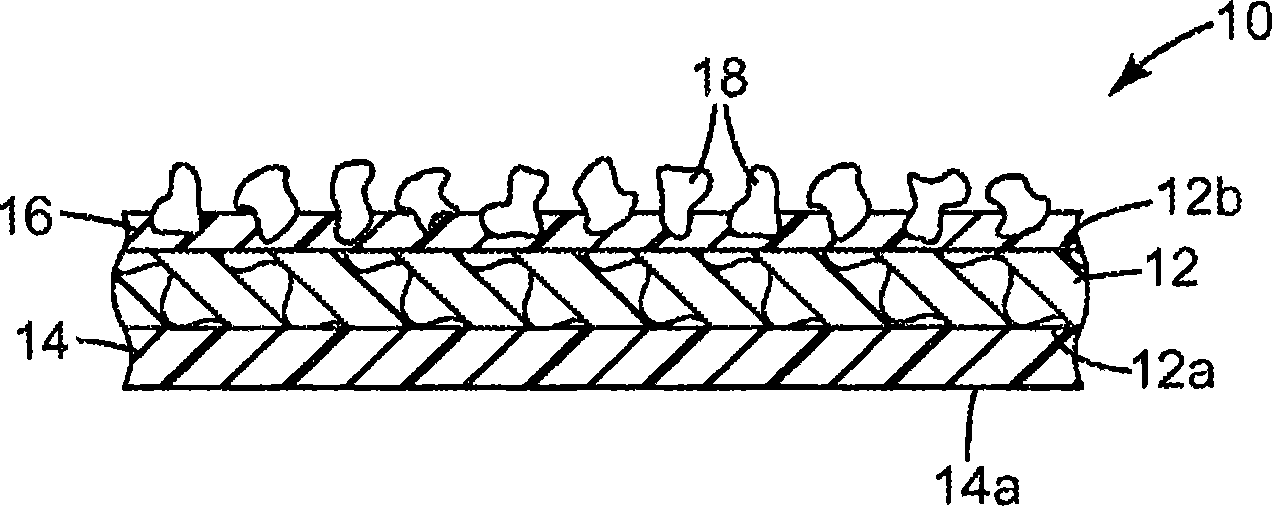

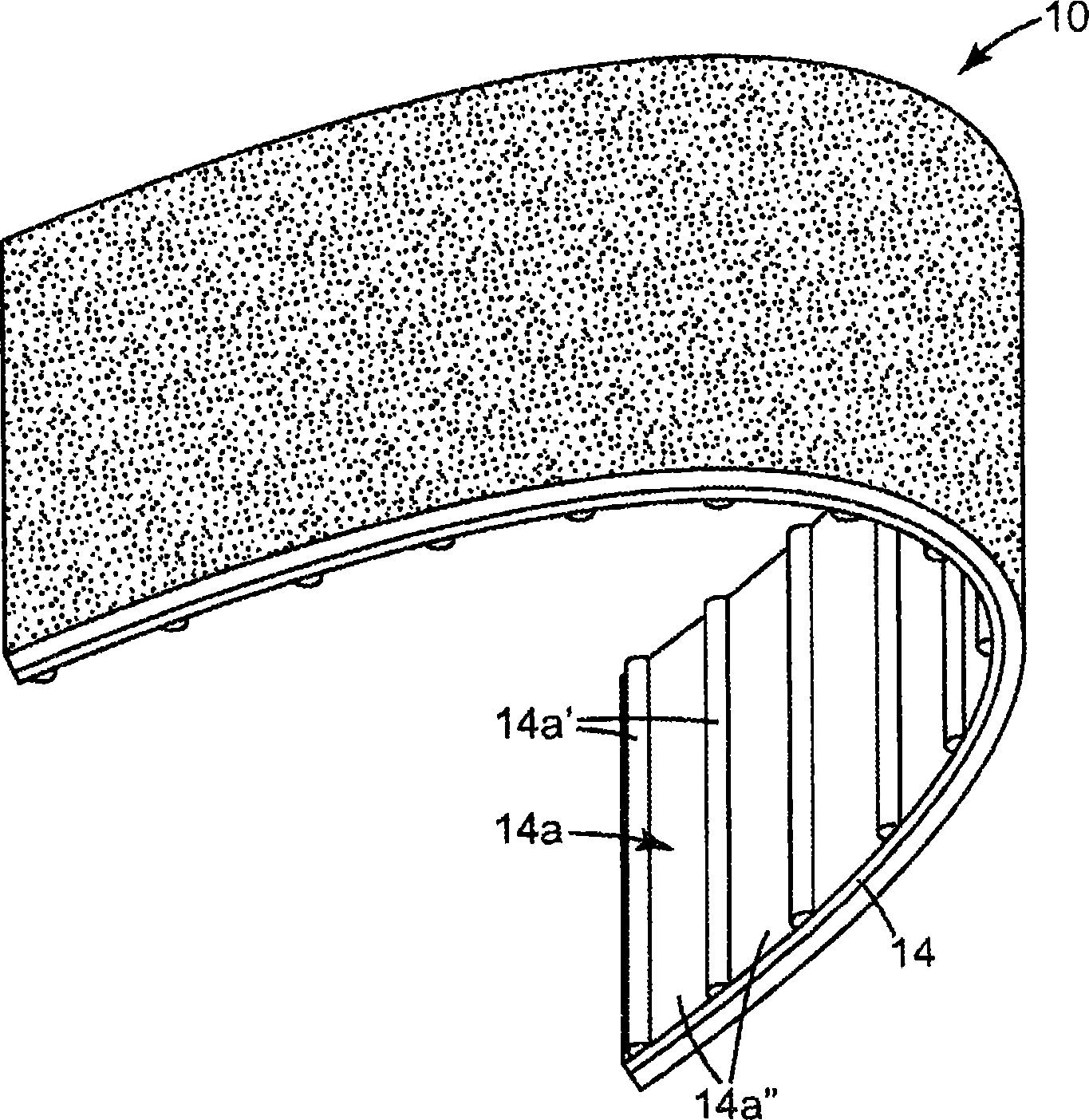

[0088] In each of the examples shown below, sandpaper commercially available from 3M Company (St. Paul, MN) under the trade designation "216U P150 Production RN Paper A Weight, Open Coat, Fre-Cut" was used to prepare figure 1 Abrasive article 10 of the construction shown. The 216U sandpaper is a general purpose sandpaper with an A weight paper backing coated on one side with phenolic resin with alumina abrasive particles partially embedded in the phenolic resin. The second side of the sandpaper (ie, the non-abrasive side opposite the abrasive surface) was then coated with one of the non-slip coatings described below.

[0089] For each of Examples 1-8, the resulting non-slip coating 14 has a low tack to allow the non-slip coating 14 to be folded onto itself and allow the contacting surfaces to be easily separated without damaging the non-slip coating 14 surface, Neither will the base backing 12 be damaged or separated from it.

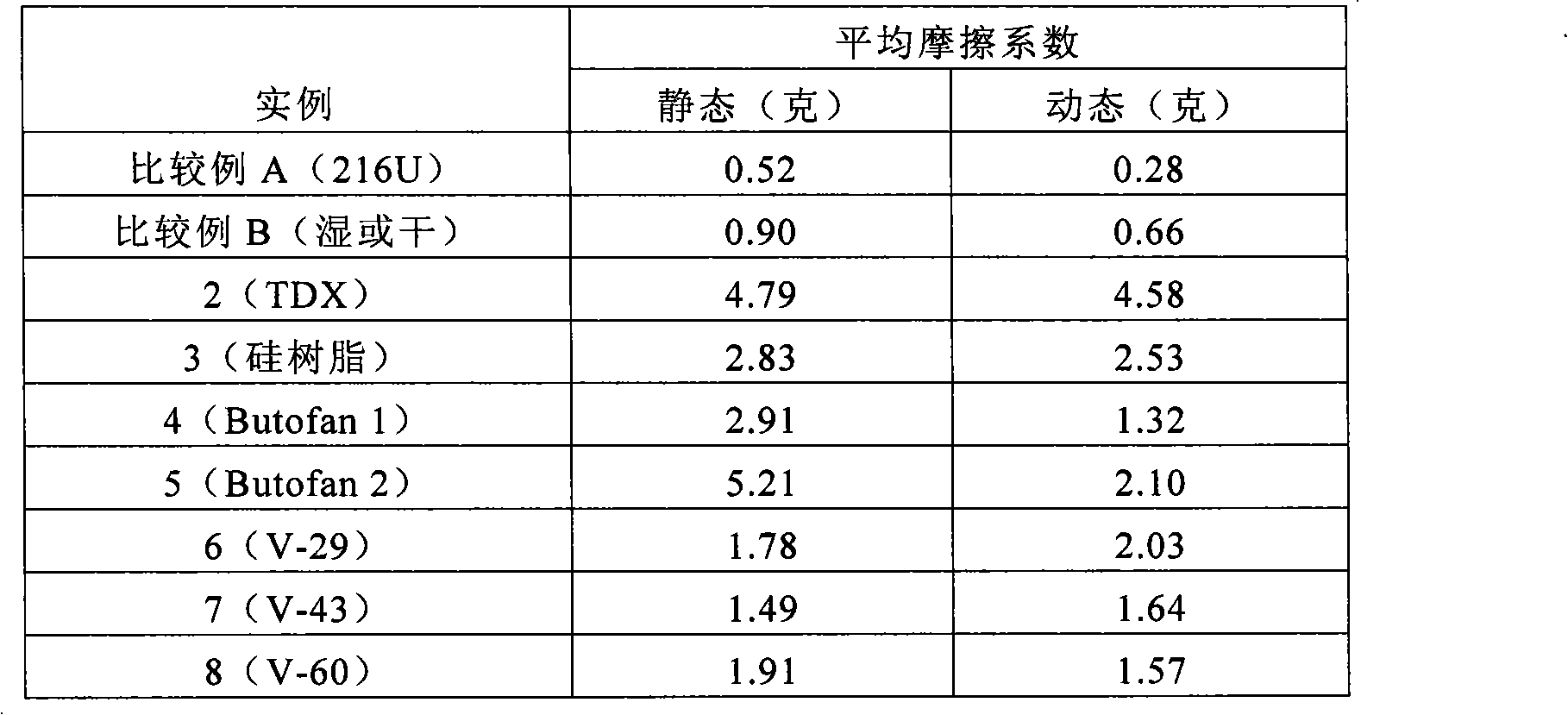

[0090] For each of Examples 2-8 and two compara...

example 1

[0096] Example 1 is 216U sandpaper with the second side coated with 90% by weight Kraton D-1161K SIS block copolymer (sold by Kraton Polymers, LLC, Houston, Texas) with 10% by weight Wingtack Plus tackifier ( marketed by Sartomer Company Inc., Exton, Pennsylvania), which was dissolved in toluene such that the resulting solution contained approximately 40% solids by weight. The blend was coated onto the backing layer 12 using a knife coater to a thickness of 1.5 mils and then allowed to dry at ambient conditions such that the toluene evaporated completely. The average coefficient of friction for Example 1 was not measured and therefore not included in Table 1.

example 2

[0098] Example 2 is 216U sandpaper in which the second side is coated with an acrylic hot melt adhesive, which is obtained by exposing the liquid monomer mixture in an ethylene-vinyl acetate (EVA) pouch to ultraviolet light to first render the mixture partially prepared by polymerization. The liquid monomer mixture included 14% by weight 2-ethylhexyl acrylate, 42% by weight butyl acrylate, 44% by weight methyl acrylate, and the following additives (parts per hundred additives - ppha): Irgacure 651 photoinitiator (sold by Ciba-Geigy Corporation, Hawthorne, New York) at 0.17 ppha, isooctyl thioglycolate at 0.06 ppha, hexanediol diacrylate at 0.004 ppha, alpha benzophenone at 0.092 ppha and Irganox 1076 antioxidant at 0.4 ppha (sold by Ciba Specialty Chemicals Corporation, Tarrytown, New York). The partially polymerized monomer mixture was then blended with the EVA pouch using a twin screw extruder such that the partially polymerized monomer mixture blend also included 4 ppha of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating mass | aaaaa | aaaaa |

| dynamic friction coefficient | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com