System and method of operating internal combustion engines at fuel rich low-temperature combustion mode as an on-board reformer for solid oxide fuel cell-powered vehicles

A fuel cell and reformer technology, which is applied to the arrangement of multiple different prime movers of fuel cells, combustion engines, and general power plants, and can solve problems such as low fuel efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

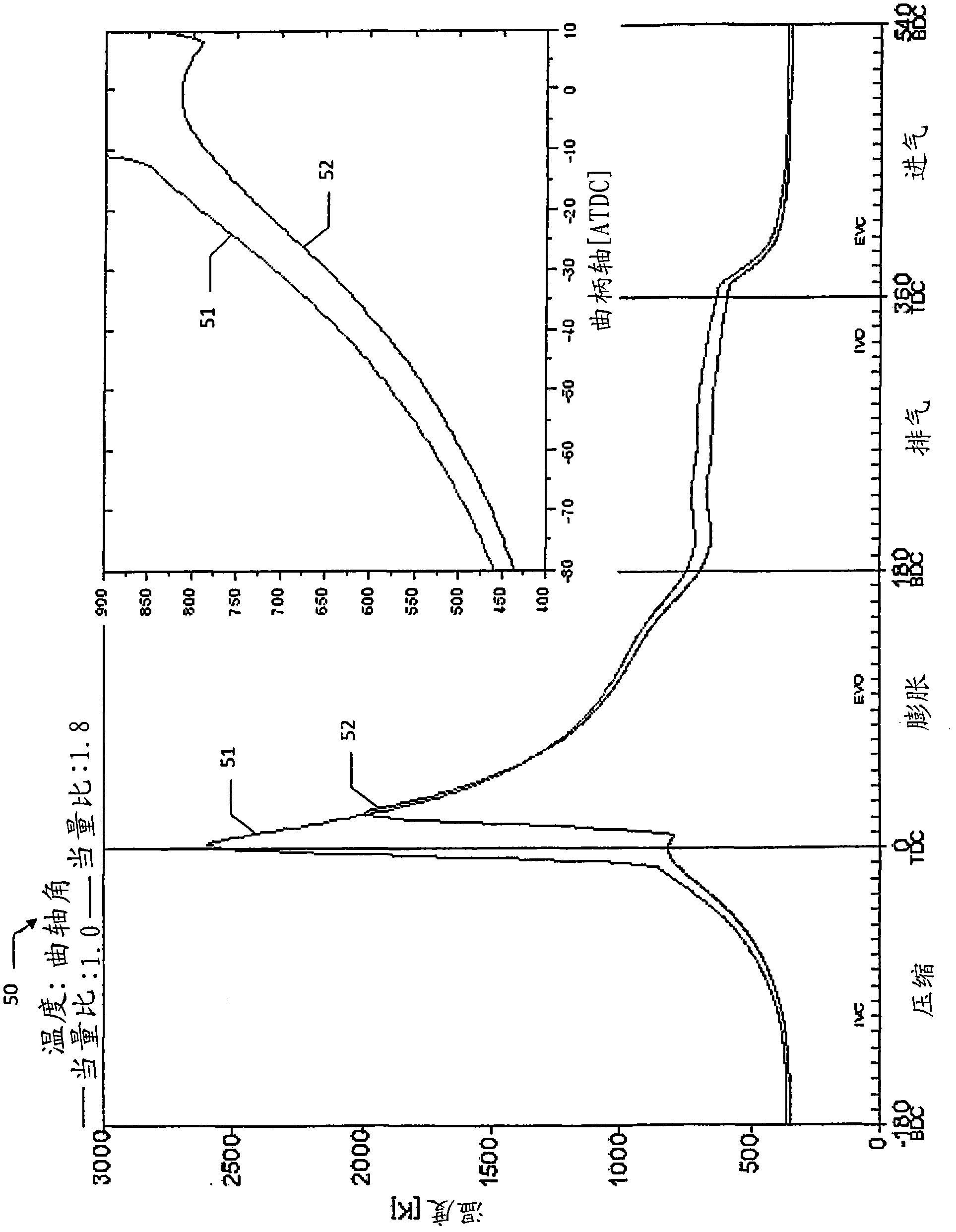

[0036] figure 1 is a graph 50 showing how increasing the amount of premixed fuel in rich conditions can induce low temperature combustion with only 10% EGR. The data used for graph 50 was generated by computer simulations assuming n-heptane as the fuel and a compression ratio of 16. In Comparative Example 51, the premixed fuel provided an oil-air ratio of 1.0, and the gas temperature reached 2500K through the combustion process. This temperature is too high and the low temperature combustion mode cannot be obtained for the comparative example. In Example 52, the oil to air ratio is 1.8. The peak gas temperature is below 2000 K, indicating that the combustion temperature has been reduced considerably enough to induce a low temperature combustion mode.

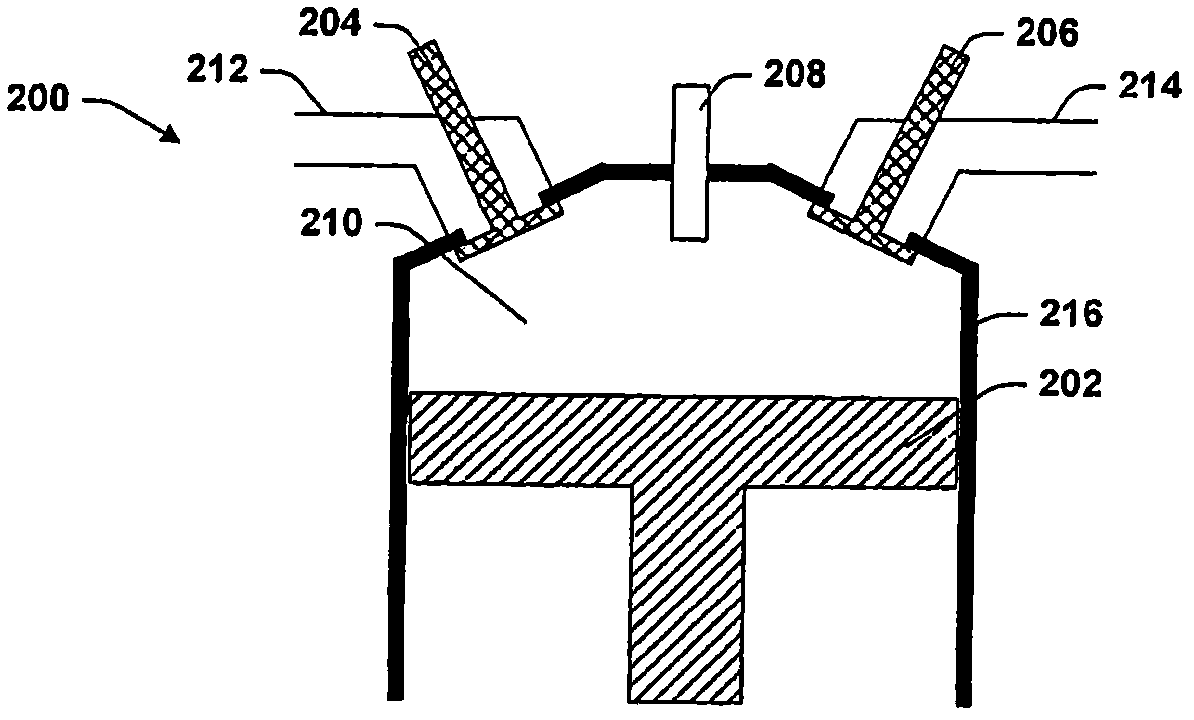

[0037] figure 2 A schematic diagram of a combustion chamber 200 of a diesel engine 300 that may be designed for the low temperature combustion mode of the present invention is provided. Combustion chamber 200 is equipped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com