Direct distillation technology for 2-methylnaphthalene

A technology of methyl naphthalene and mixed methyl naphthalene, applied in the field of distillation technology, can solve problems such as increasing solvent recovery process, increasing solvent consumption, increasing cost, etc., and achieves improved thermal efficiency and energy utilization rate, guaranteed product quality, and zero emissions. The effect of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

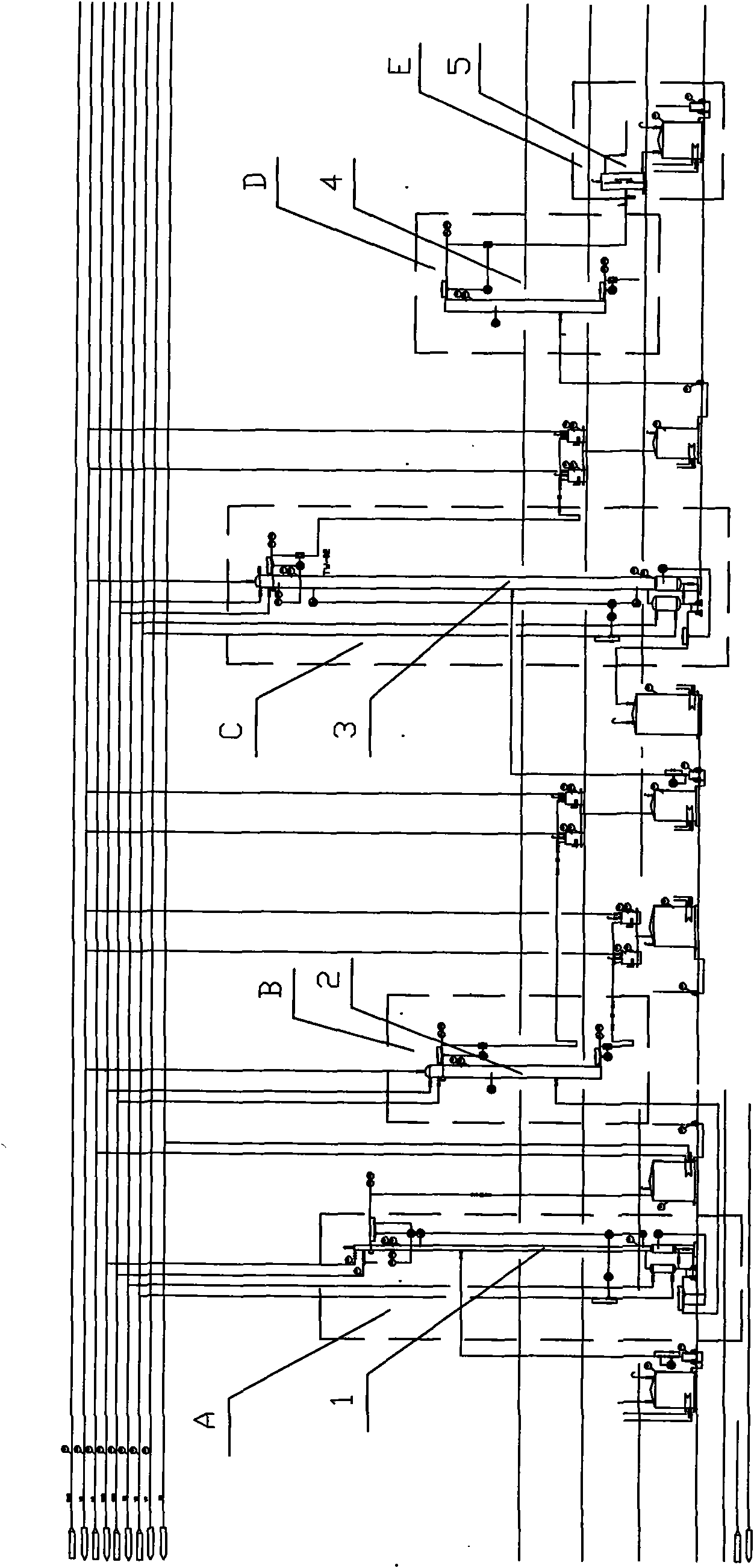

[0021] A kind of direct distillation technique of 2-methylnaphthalene, process step is as follows:

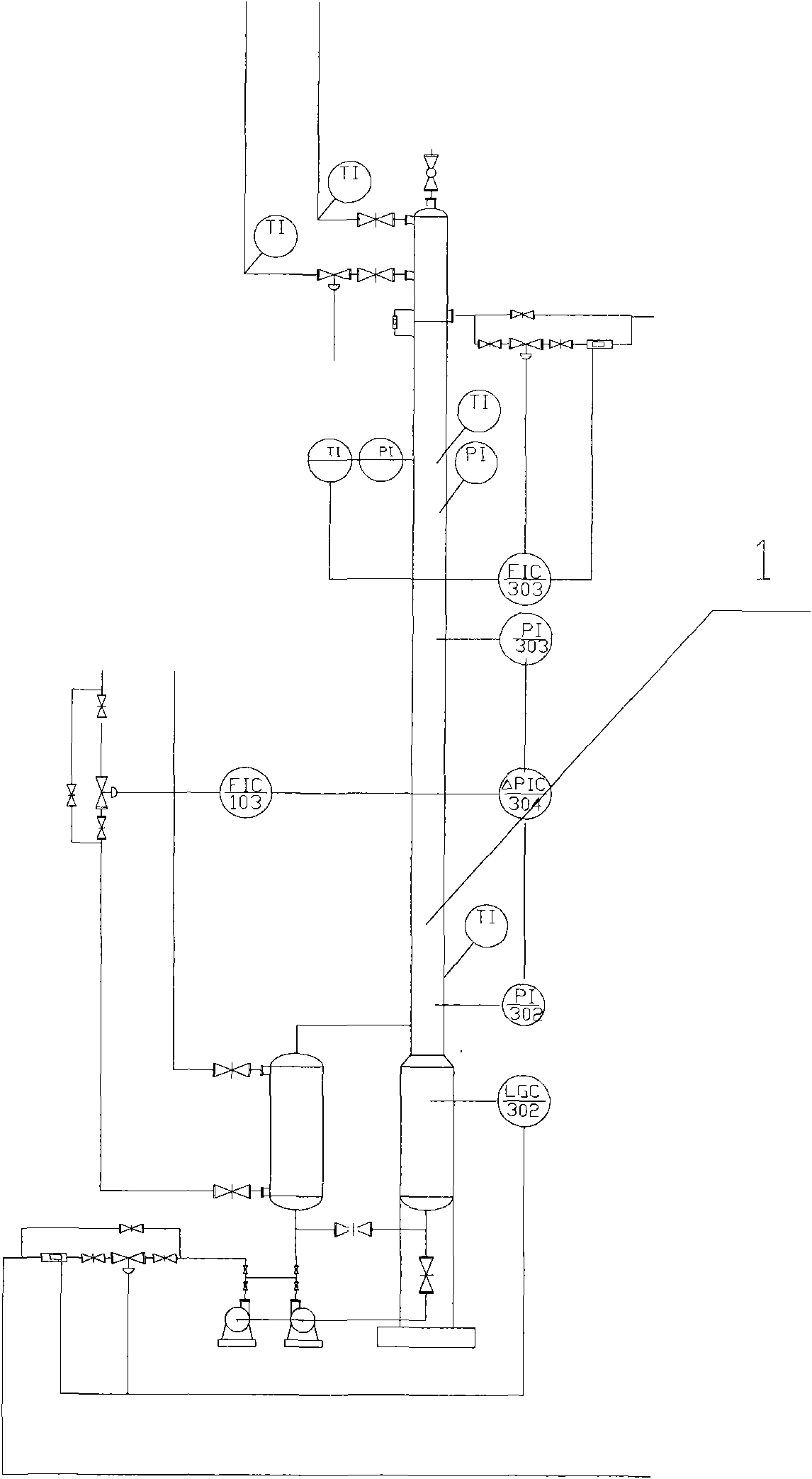

[0022] After A, mixed methyl naphthalene cuts the naphthalene cut from the top of the atmospheric pressure primary distillation tower (1), the tower bottom liquid directly enters the negative pressure flash evaporator (2) to separate under the heat preservation state;

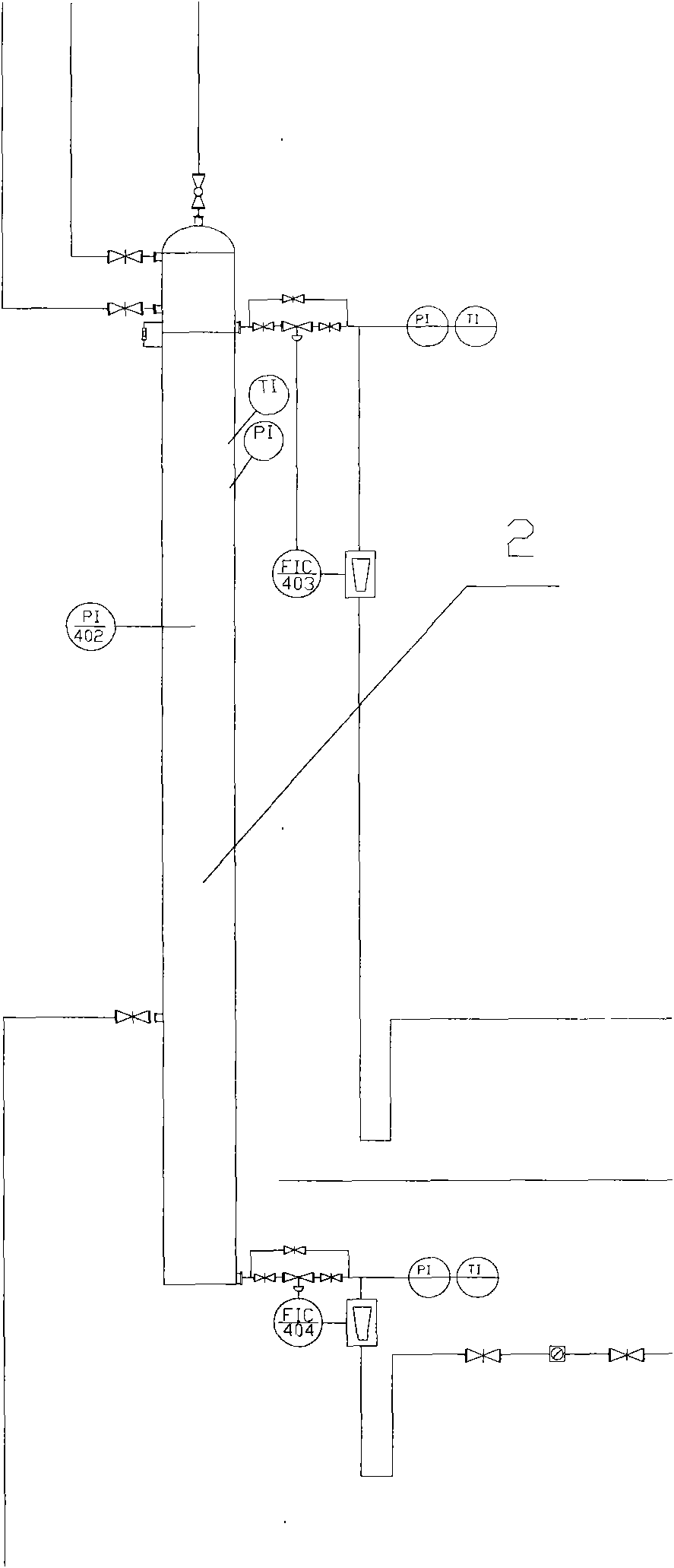

[0023] B, extract the mixed methylnaphthalene from the bottom of the negative pressure flash evaporator (2), and extract the 2-methylnaphthalene cut from the top of the negative pressure flash evaporator (2);

[0024] C, extract the 2-methylnaphthalene cut from the top of the negative pressure flash evaporator (2) and enter the negative pressure rectification tower (3), carry out negative pressure rectification, and extract the mixed fraction from the bottom of the negative pressure rectification tower (3) tower Methylnaphthalene enters the raw material tank for reuse, and 2-methylnaphthalene is extracted from t...

Embodiment 2

[0028] A kind of direct distillation technique of 2-methylnaphthalene, process step is as follows:

[0029] After A, mixed methyl naphthalene cuts the naphthalene cut from the top of the atmospheric pressure primary distillation tower (1), the tower bottom liquid directly enters the negative pressure flash evaporator (2) to separate under the heat preservation state;

[0030] B, extract the mixed methylnaphthalene from the bottom of the negative pressure flash evaporator (2), and extract the 2-methylnaphthalene cut from the top of the negative pressure flash evaporator (2);

[0031] C, extract the 2-methylnaphthalene cut from the top of the negative pressure flash evaporator (2) and enter the negative pressure rectification tower (3), carry out negative pressure rectification, and extract the mixed fraction from the bottom of the negative pressure rectification tower (3) tower Methylnaphthalene enters the raw material tank for reuse, and 2-methylnaphthalene is extracted from t...

Embodiment 3

[0034] The process steps of this embodiment are the same as those in Example 1. The pressure at the top of the atmospheric initial distillation tower (1) is normal pressure, the temperature at the top of the tower is 215° C., and the reflux ratio is 10. The vacuum degree of the negative pressure rectification tower (3) tower top pressure is 90%, the tower top temperature is 160 ℃, and the reflux ratio is 15.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com