Distributed optical fiber temperature measurement-based fire early warning method for belt conveyor

A technology of belt conveyor and distributed optical fiber, applied in the direction of fire prevention, earthwork drilling, underground transportation, etc., can solve the problems of high false alarm rate, poor use effect, inability to realize distributed and continuous monitoring of transportation lanes, etc. , to achieve the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

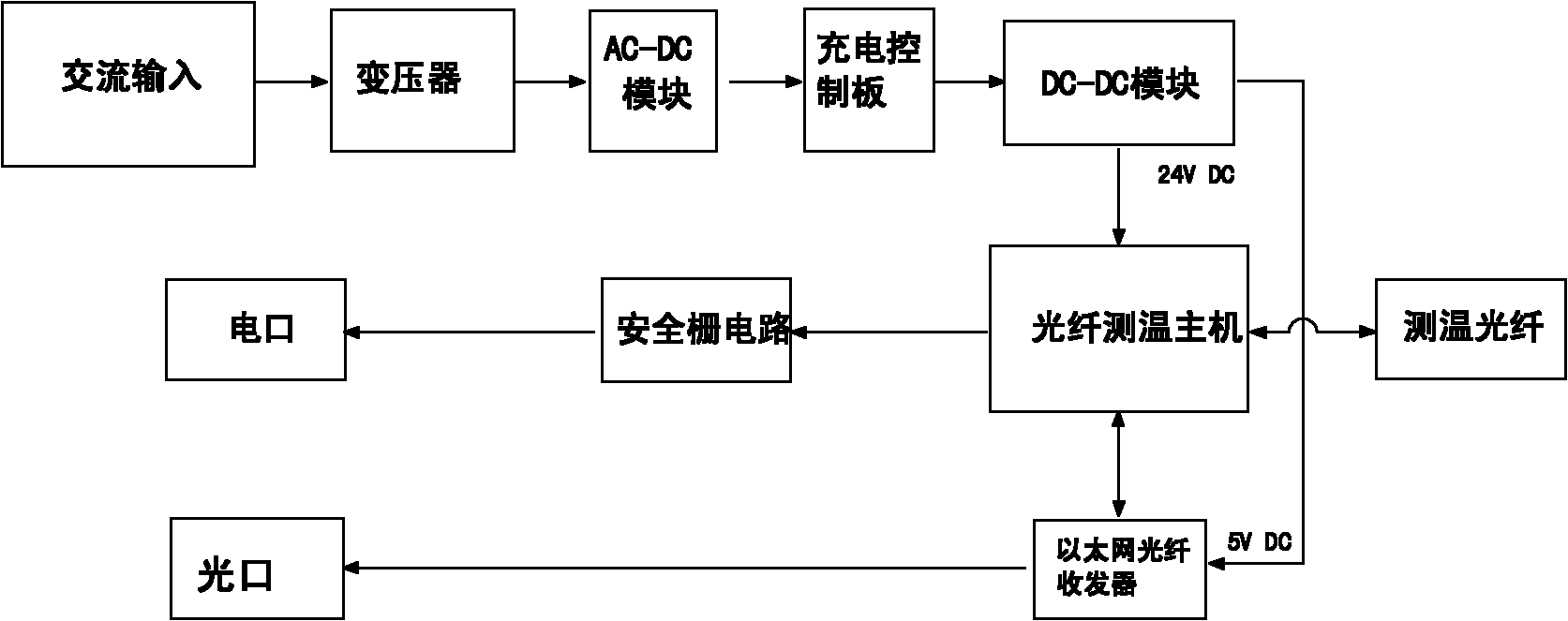

[0046] figure 1 It is a schematic diagram of the electrical connection of distributed optical fibers in the belt conveyor fire warning method based on distributed optical fiber temperature measurement, as shown in figure 1 As shown, the temperature measurement fiber optic host has an intrinsically safe optical port / electrical port output and a power input port. The optical port is connected to the host through the Ethernet optical fiber transceiver; the electrical port is isolated by the safety barrier and outputs intrinsically safe signals. The host has two optical fiber input measurement channels, namely 1 and 2 channels. The power input interface can be connected to 50Hz AC voltage levels: 127V / 220V / 380V / 660V AC; the power supply is divided into two outputs, one output is 24VDC for the internal DTS host, and the other is 24VDC for the Ethernet fiber optic transceiver.

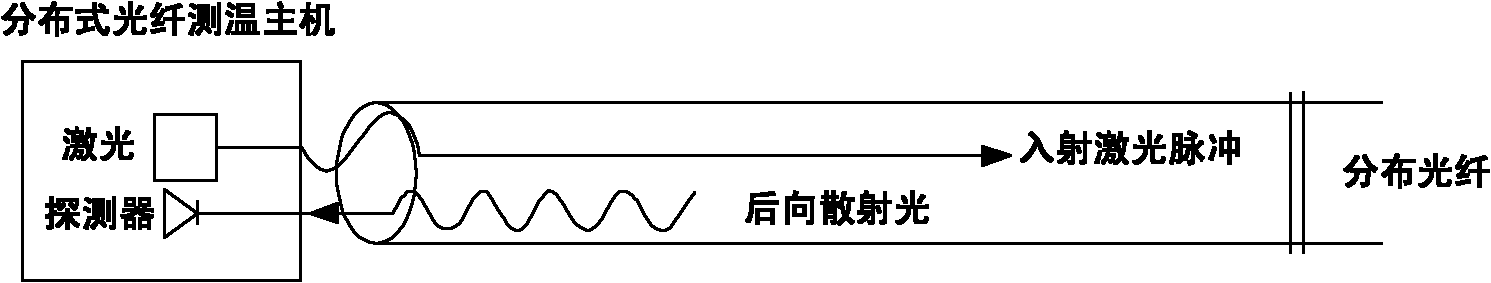

[0047] The optical fiber temperature measurement host in this embodiment adopts the Raman time domain r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com