Three-station actuator cylinder structure

An actuator and three-position technology, applied in the direction of fluid pressure actuating devices, etc., can solve the problems of complex structure, high economic cost, and inability to realize mechanical limit, and achieve the effect of simple operation control and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

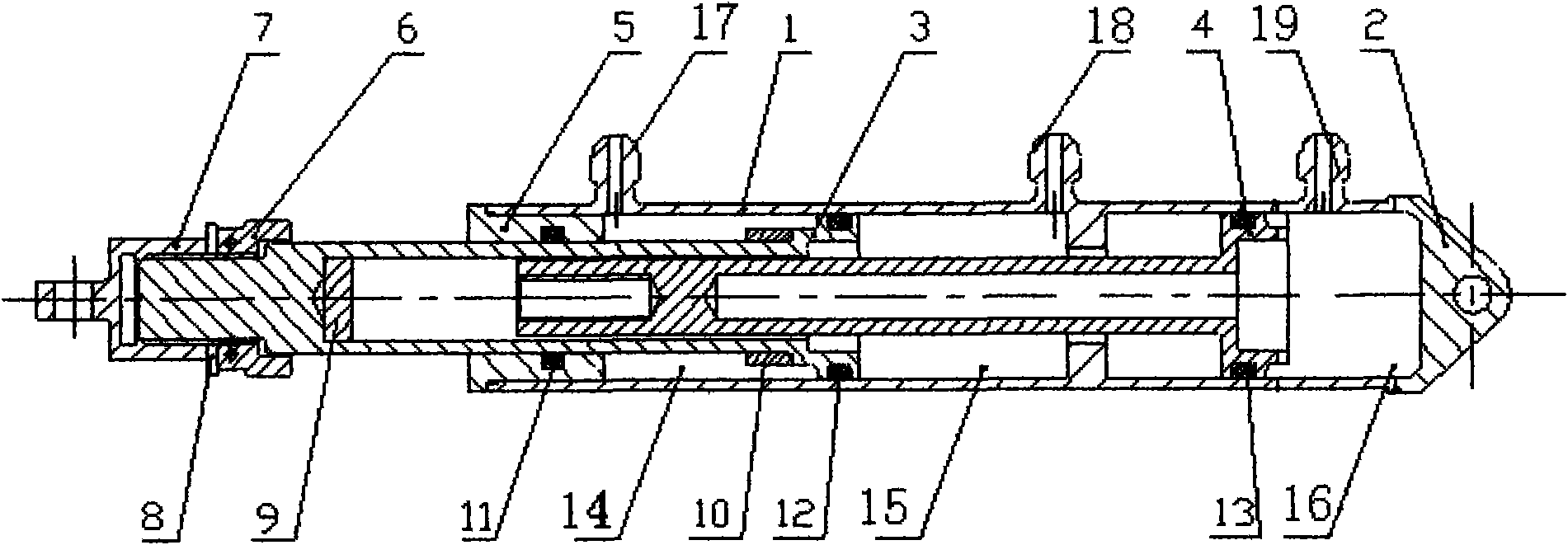

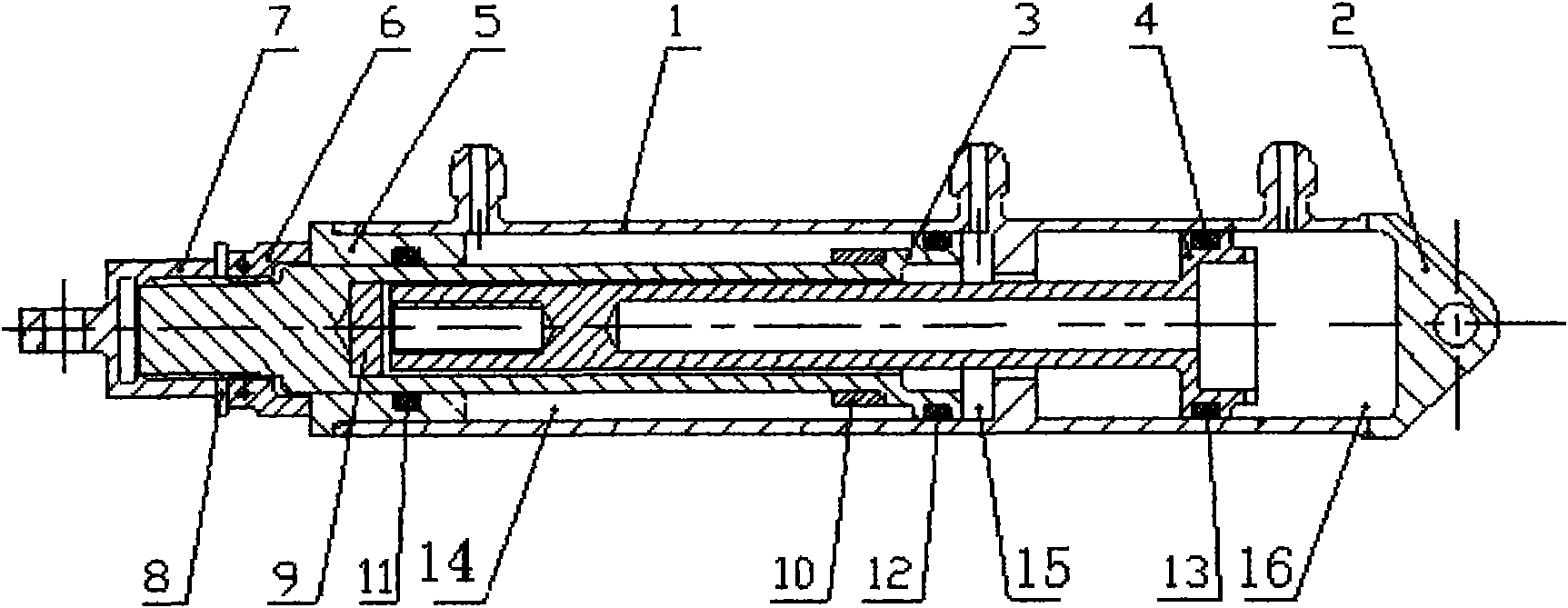

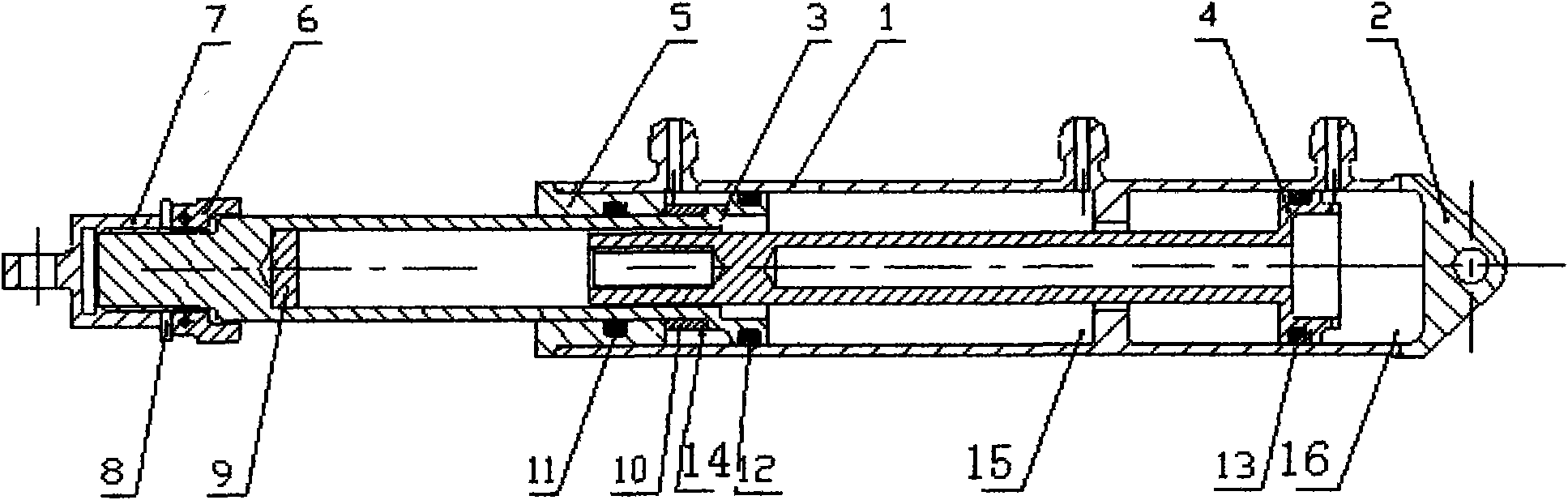

[0021] This embodiment provides a three-station actuator structure, which is characterized in that: the three-station actuator structure includes an actuator cylinder 1, a tail cover 2, an active piston 3, and a limiting piston 4. Sealing section 5, reserve nut 6, tail handle 7, adjusting cushion one 8, adjusting cushion two 9, adjusting cushion three 10, sealing rubber ring one 11, sealing rubber ring two 12, sealing rubber ring three 13;

[0022] Among them: the actuating cylinder body 1 is equipped with the active piston 3 and the limiting piston 4, the actuating cylinder body 1 and the limiting piston 4 are equipped with a sealing rubber ring 313, the actuating cylinder body 1 and the active piston 3 Sealing rubber ring two 12 is installed between, and sealing rubber ring one 11 is installed between the cylinder body 1 and the sealing section 5;

[0023] The left side of the actuating cylinder body 1 is connected with the sealing section 5, and the right side of the actuating c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com