Piezoelectric switch type valve positioner control method and piezoelectric switch type valve positioner control system

A valve positioner, piezoelectric switch technology, applied in the direction of valve details, valve devices, valve operation/release devices, etc., can solve the problems of long adjustment time, large duty cycle, overshoot, etc., and achieve smooth control and suppression The effect of valve position disturbance and overshoot prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

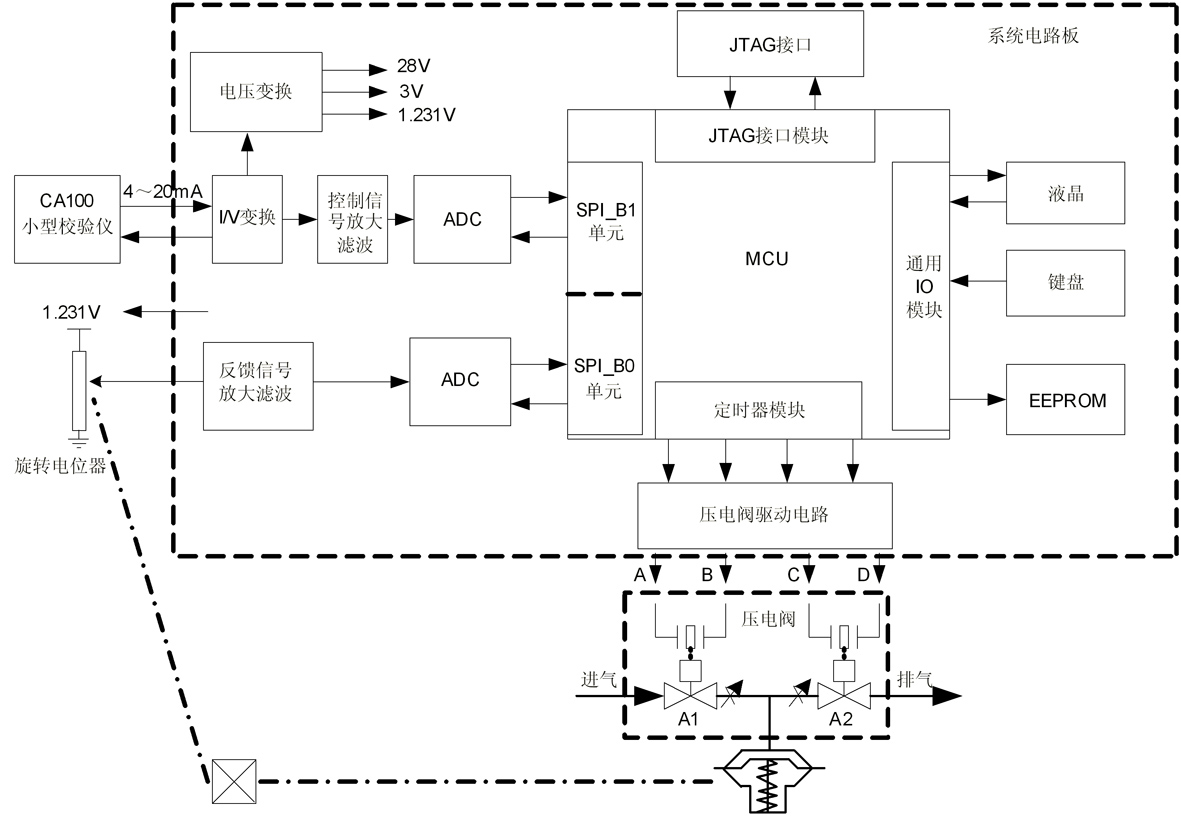

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

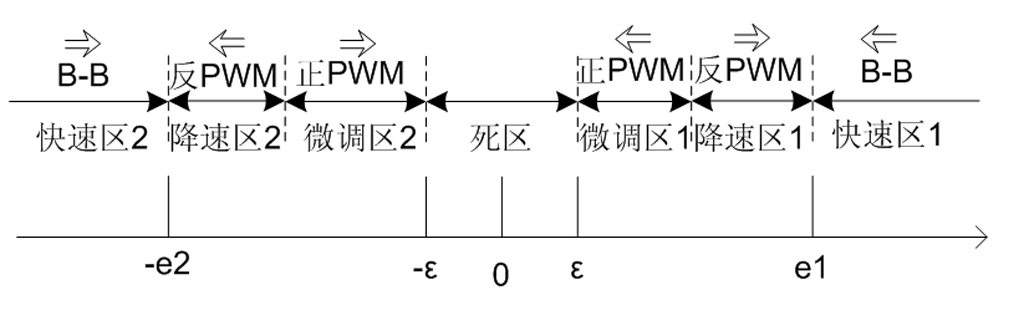

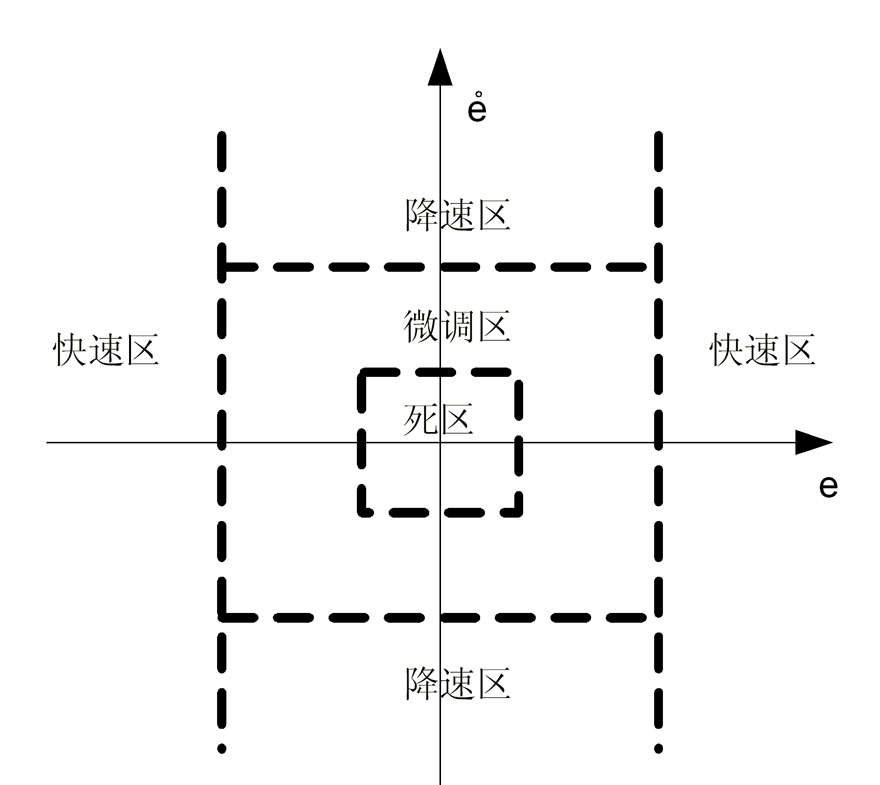

[0032] The schematic diagram of the five-step switching method with reverse PWM in the system of the present invention is as follows figure 1 shown. The direction of the arrow in the figure indicates the direction of the gas force. When the absolute value of the error is large, use B-B control to quickly reduce the error; when the absolute value of the error is small but the rate of error change is large, use reverse PWM control to quickly reduce the rate of error change; when the absolute value of the error When the error rate is small and the error change rate is small, the positive PWM control is used to slowly approach the target value; when the valve position enters the dead zone smoothly, the control valve position is maintained. The phase plane graph of the algorithm is as follows figure 2 Shown, where the derivative of the error represents the rate of chang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com