Gas online detection device in protective gas heat treatment furnace

A technology of heat treatment furnace and protective gas, which is applied to measuring devices, furnace control devices, furnaces, etc., can solve the problems of increasing gas consumption and affecting the brightness of workpieces, and achieve the effect of improving production safety and improving the processing quality of pipe fittings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific embodiments and drawings, but the present invention is not limited to this embodiment.

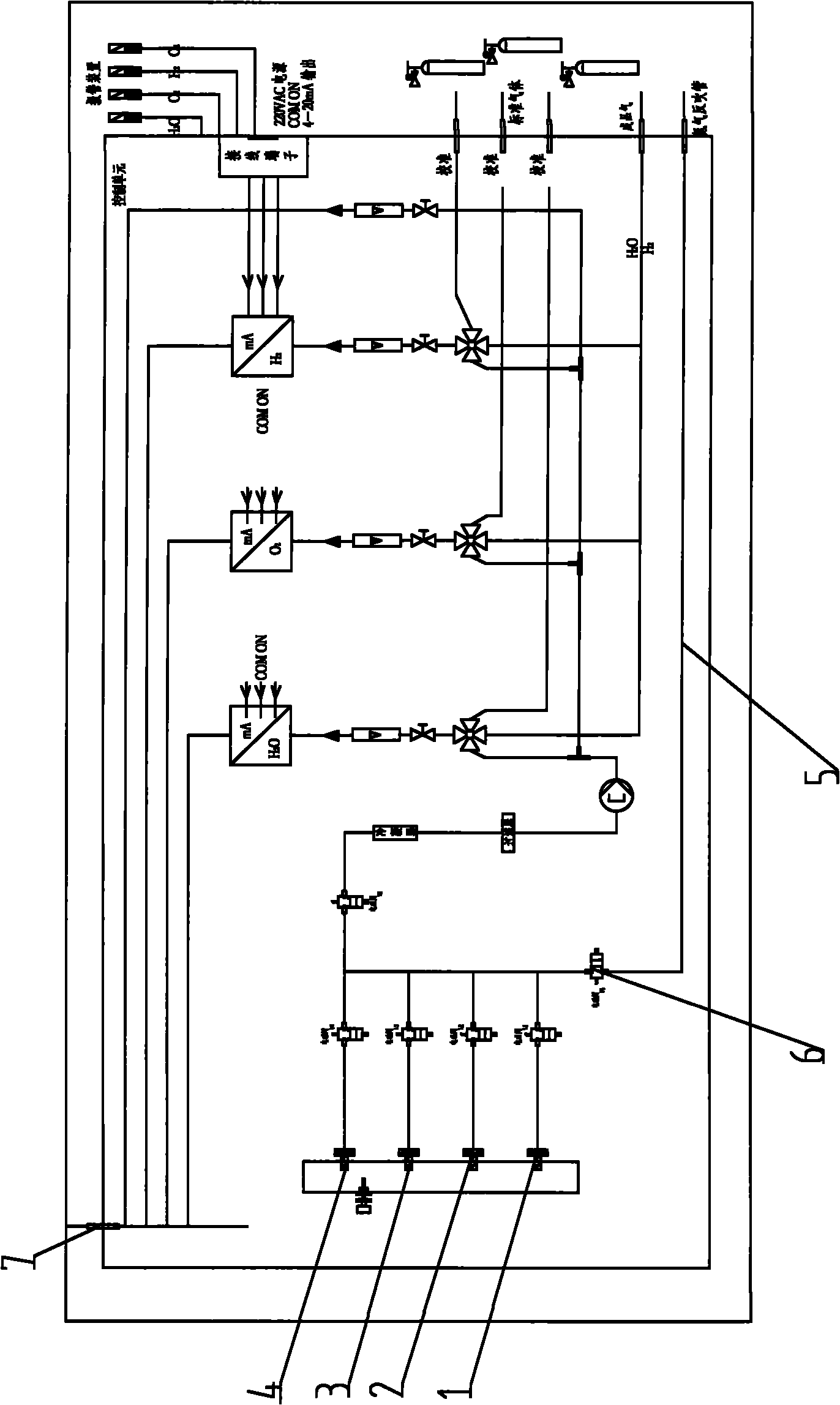

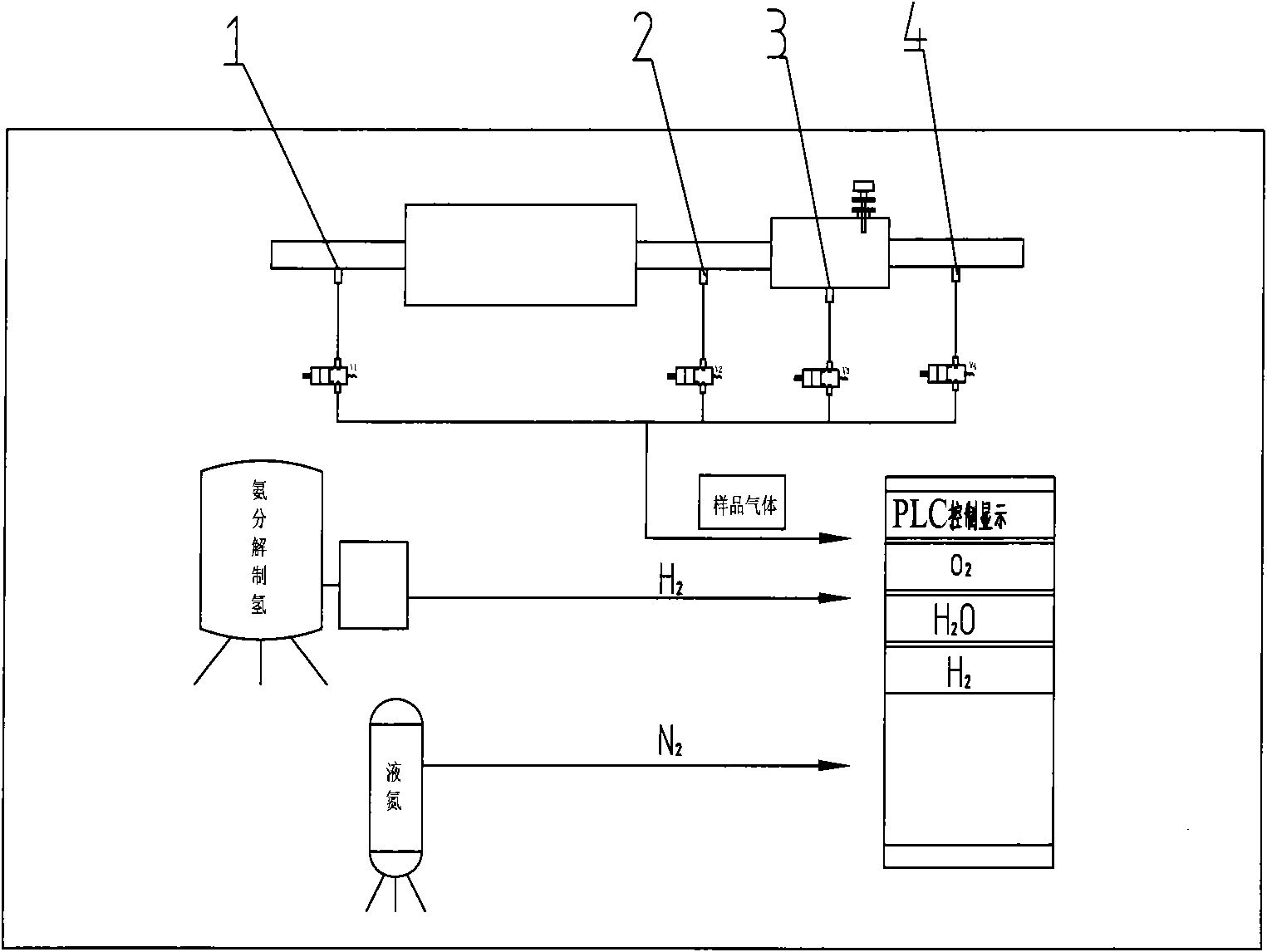

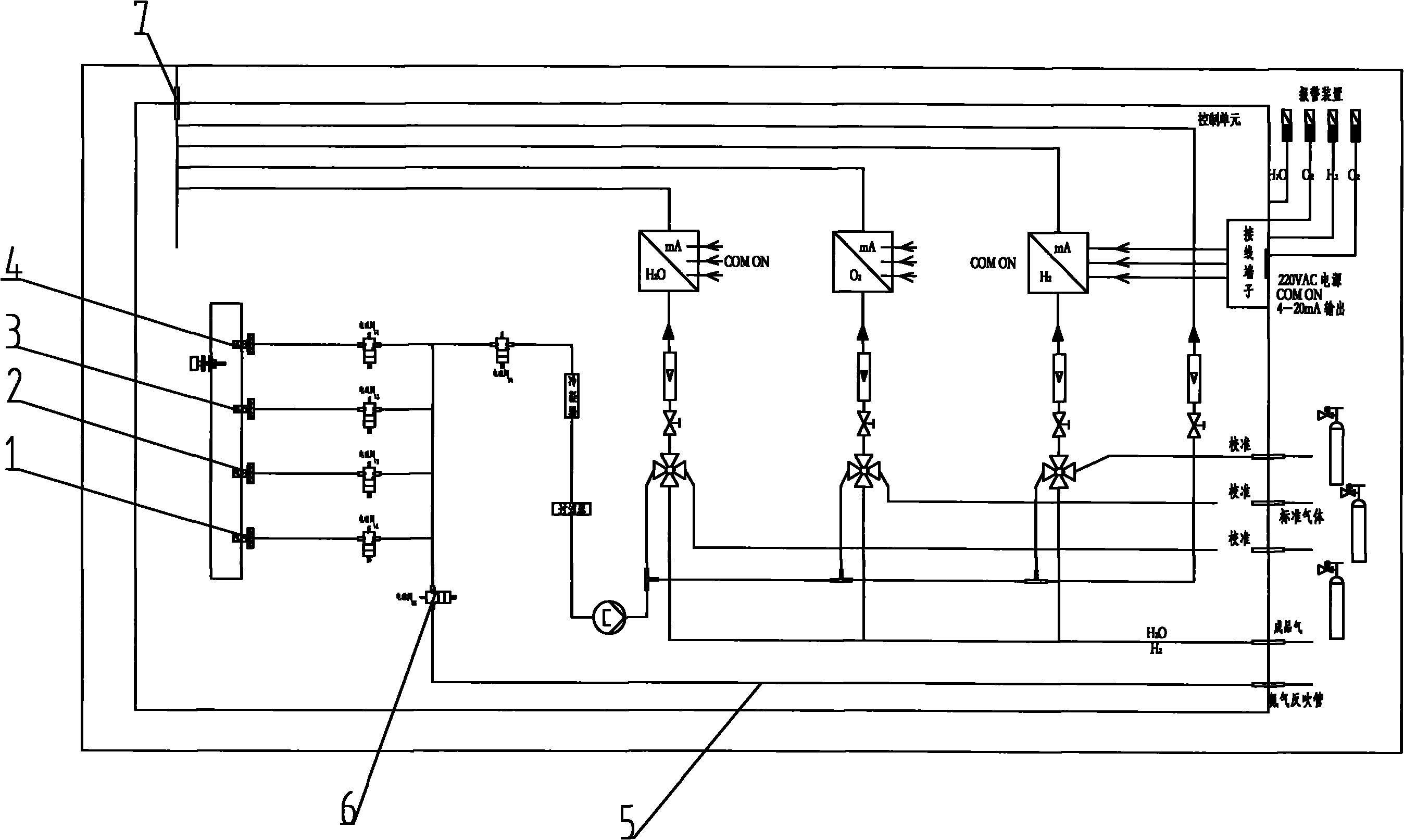

[0020] Such as figure 1 and 2 As shown, according to the working principle of the gas on-line detection device in the shielding gas heat treatment furnace of this embodiment, from the first sampling port 1 located in the preheating passage area of the shielding gas heat treatment furnace, to the heating chamber area of the shielding gas heat treatment furnace Sample gas is collected in the second sampling port 2, the third sampling port 3 located in the spray cooling zone, and the fourth sampling port 4 located in the cooling channel area of the protective gas heat treatment furnace. After mixing, the sample gas is cooled by a condenser and filtered by a filter , under the action of the air pump, respectively enter the water analyzer (CI2000-DP), oxygen analyzer (CI2000-DH) and hydrogen analyze...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com