Fiber bragg grating vibration sensing component, fiber bragg grating vibration sensing device, vibration measuring system and method

A fiber grating and vibration sensing technology, which is used in measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problem of low measurement accuracy, and achieve the effects of strong resolution, good dynamic response and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings. In the specification, the same or similar reference numerals designate the same or similar components. The following description of the embodiments of the present invention with reference to the accompanying drawings is intended to explain the general inventive concept of the present invention, but should not be construed as a limitation of the present invention.

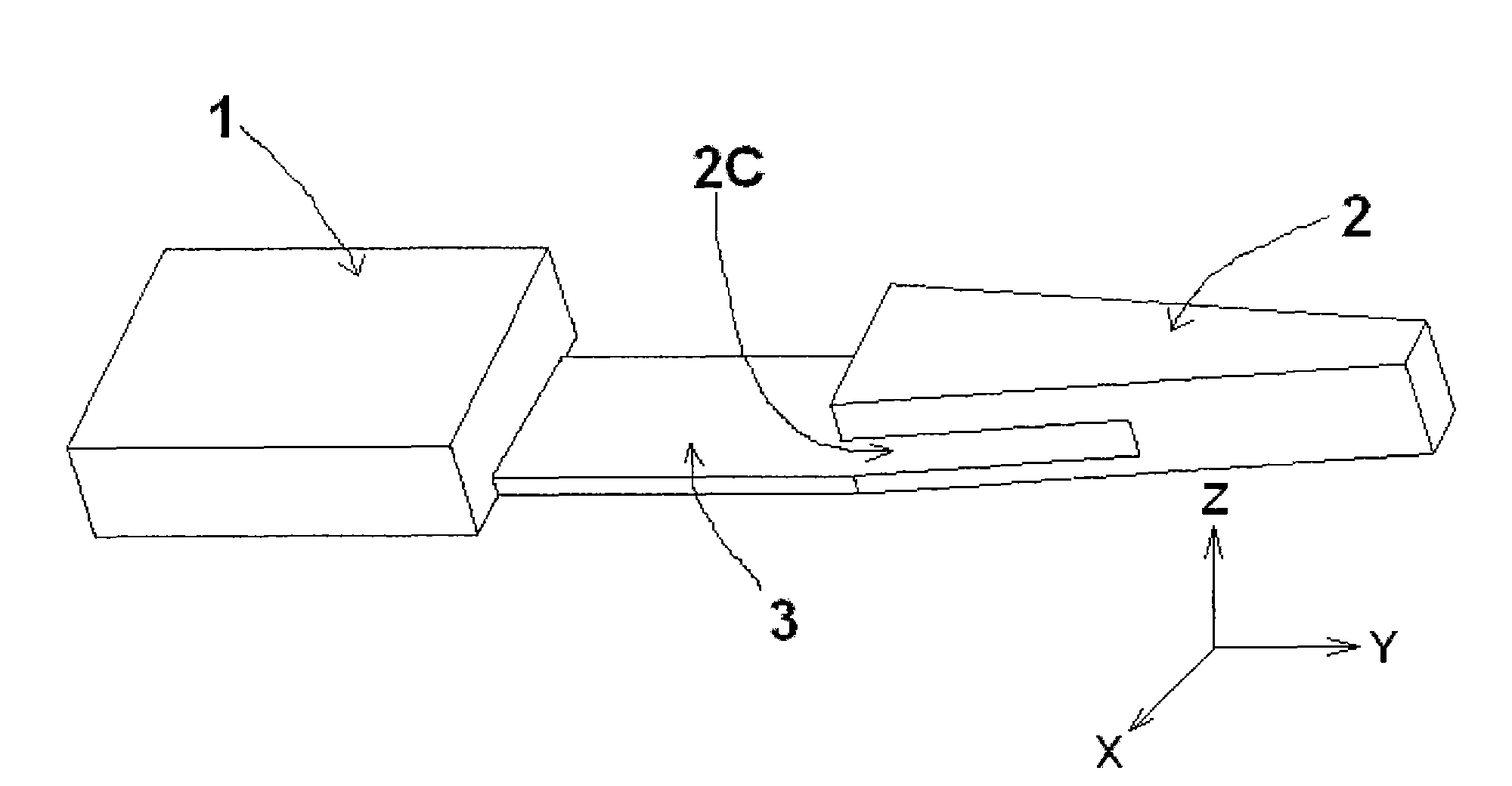

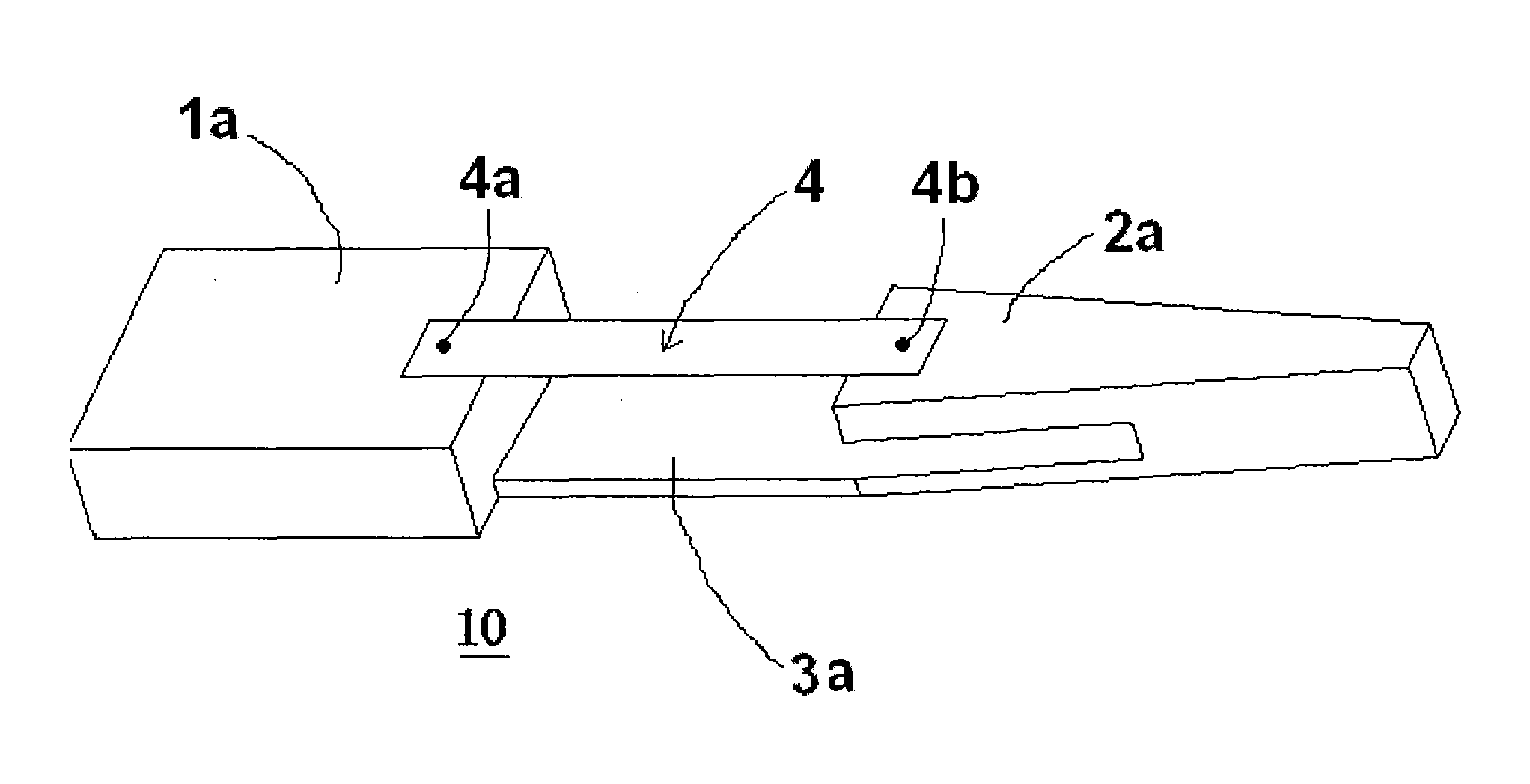

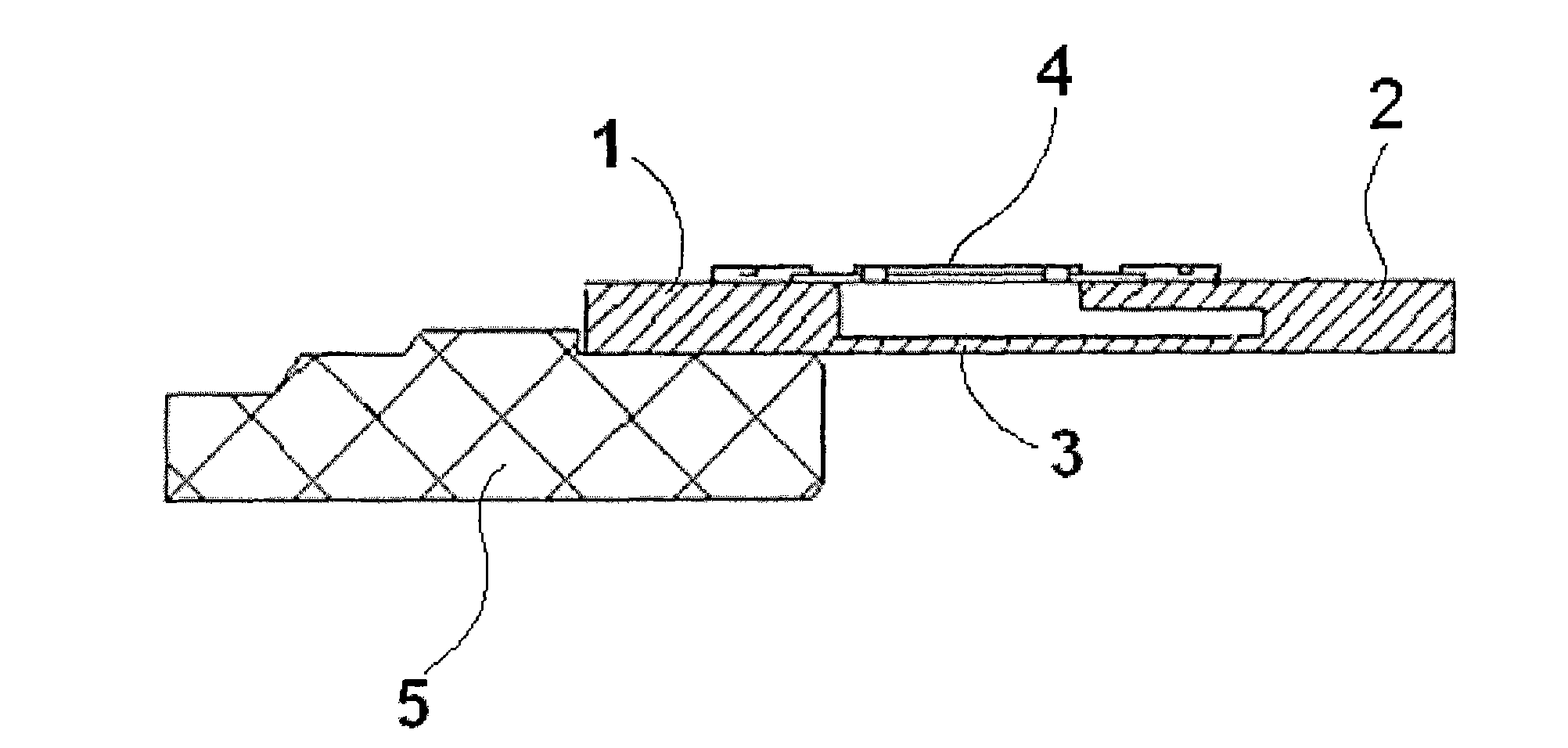

[0026] figure 1 , figure 2 with image 3 A fiber grating vibration sensing component 10 of the present invention is shown. specifically, figure 1 is a schematic diagram of the vibration structure of the fiber grating vibration sensing component of the present invention; figure 2 Shows securing the fiber grating strain gauge to the figure 1 Schematic diagram on the vibrating structure shown; image 3 display will figure 2 Schematic d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com