Method for measuring water content in a compound and water content measuring device

A measurement method and technology of raw materials, applied in the direction of material analysis, measurement device, analysis material, etc. by optical means, can solve the problems of inability to obtain moisture changes, difficult correction, and inability to measure moisture, and achieve accurate and rapid determination of moisture content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

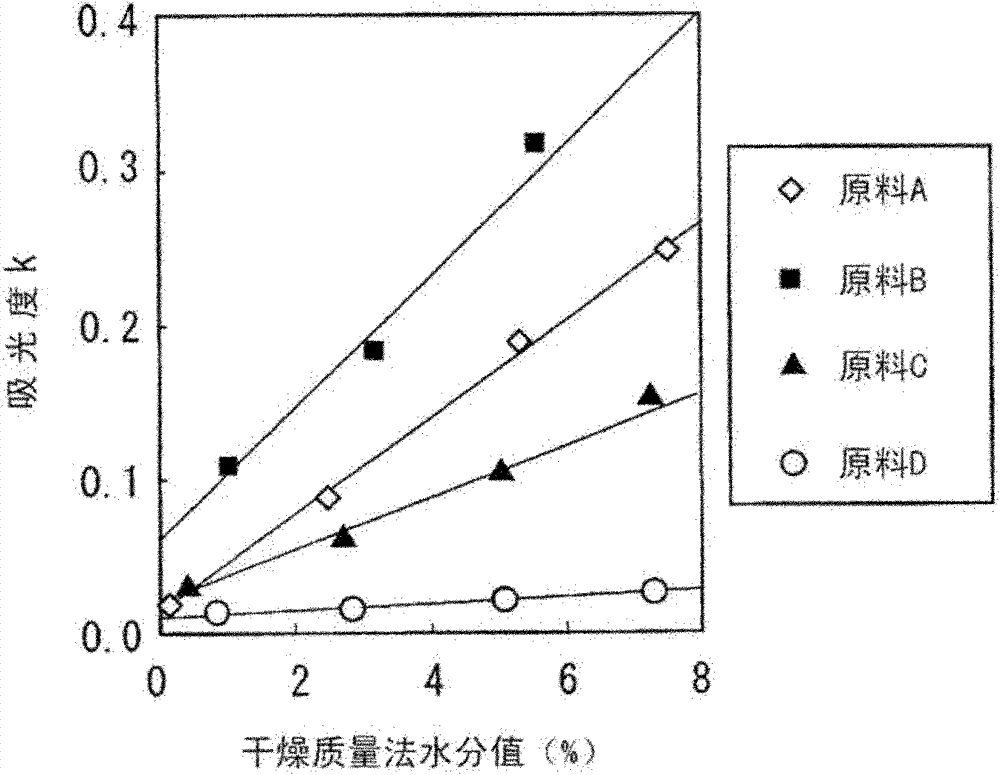

[0059] In the measurement of the water content w of the blended raw material (sintered raw material) using infrared absorption by water, the relationship between k and w (calibration curve) when the raw material is blended is changed as described above, and the constants in the above formula (4) a and b change together. Therefore, in order to obtain the correct constants a and b after changing the raw material blend, it is necessary to collect two or more samples of blended raw materials with different moisture content, and measure the water content w of each sample. C and absorbance k C . In this way, two or more measured values of different water content can be obtained, and therefore accurate constants a and b after changing the raw material composition can be obtained.

[0060] Here, if b does not change even if a changes in the formula (4) when the raw material mix is changed, the constant to be corrected is only the constant a. Therefore, the absorbance k measured...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com