Self-suction internally-cooled cutter

A self-priming, cutting tool technology, used in the manufacture of tools, metal processing machinery parts, maintenance and safety accessories, etc., can solve problems such as increased operation difficulty and product manufacturing cost, poor cooling effect, and increased equipment volume. High use value, simple structure, good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

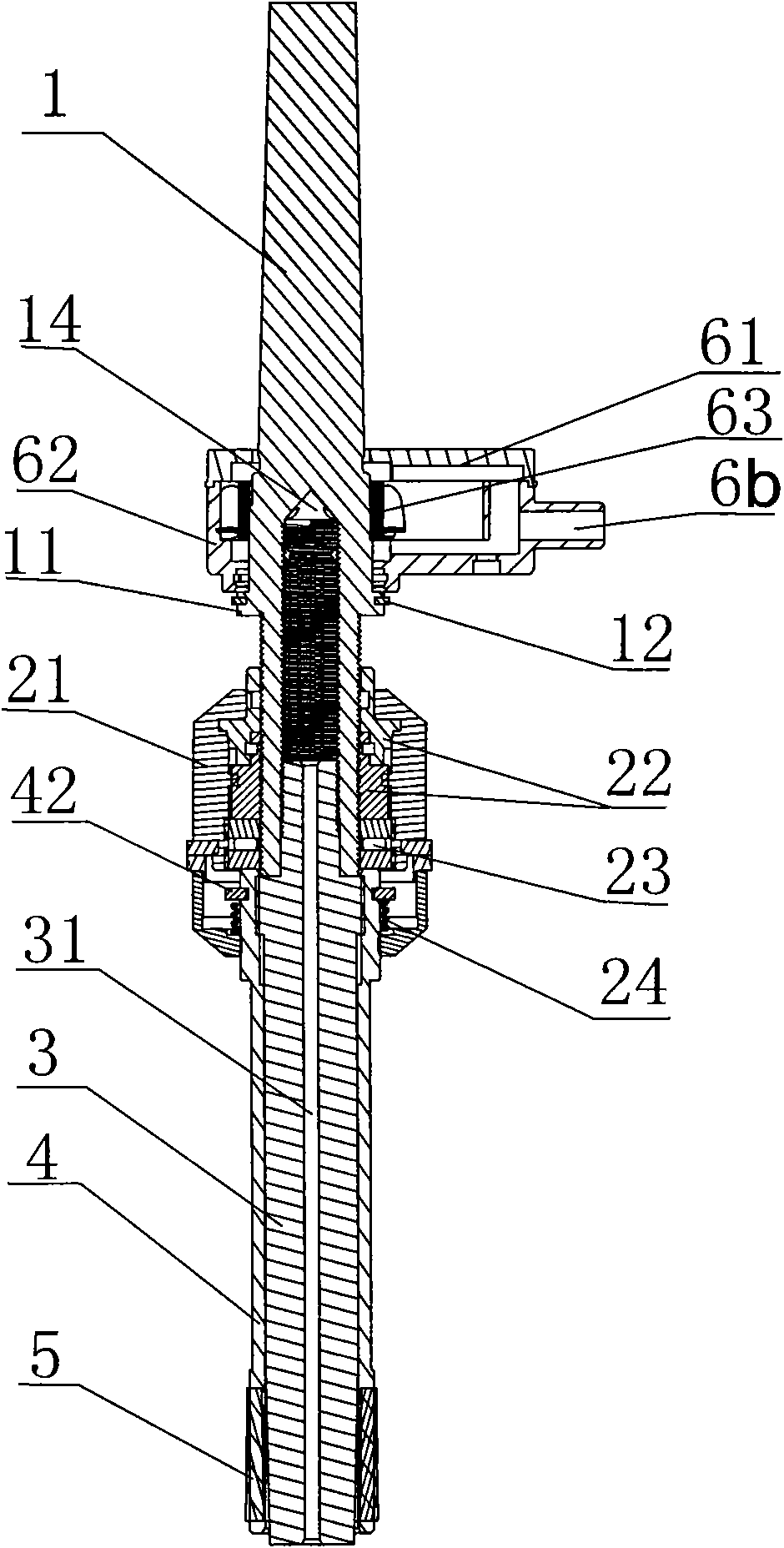

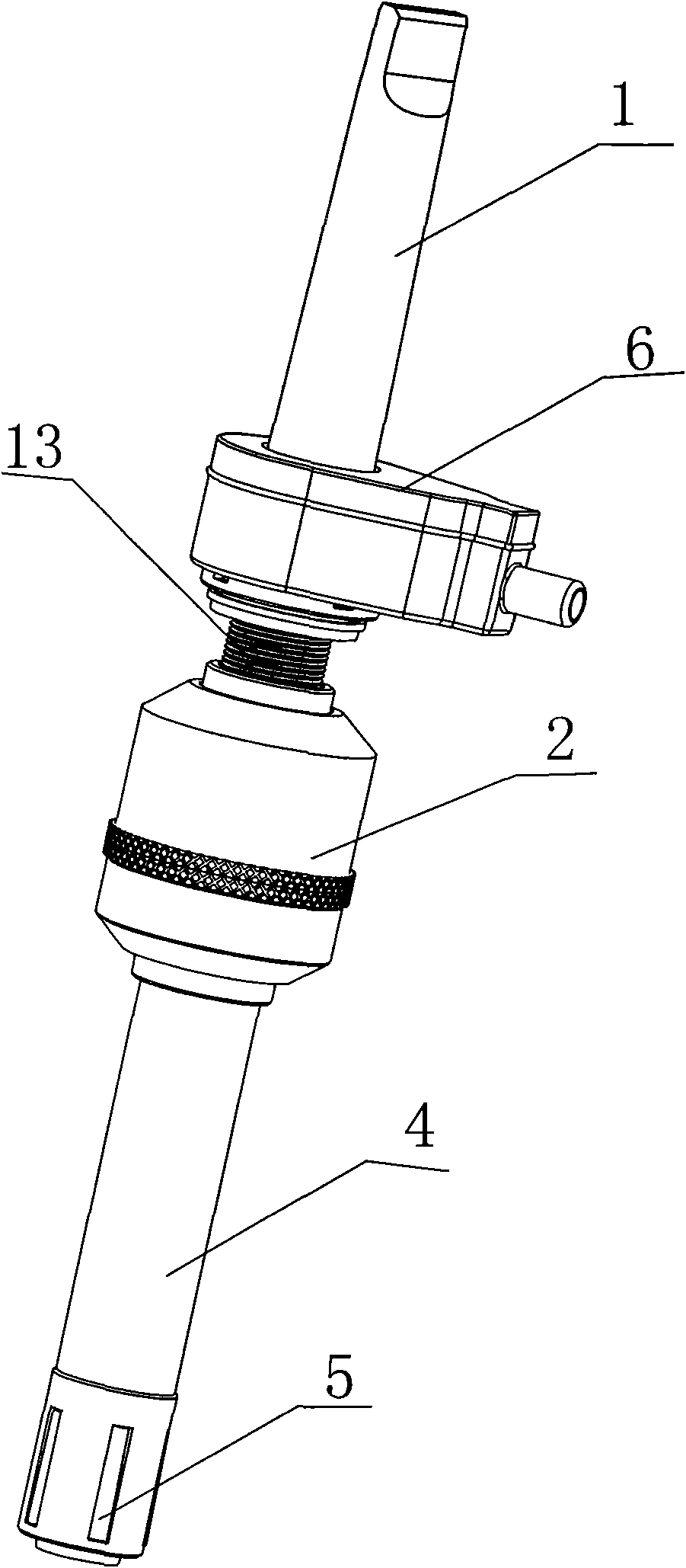

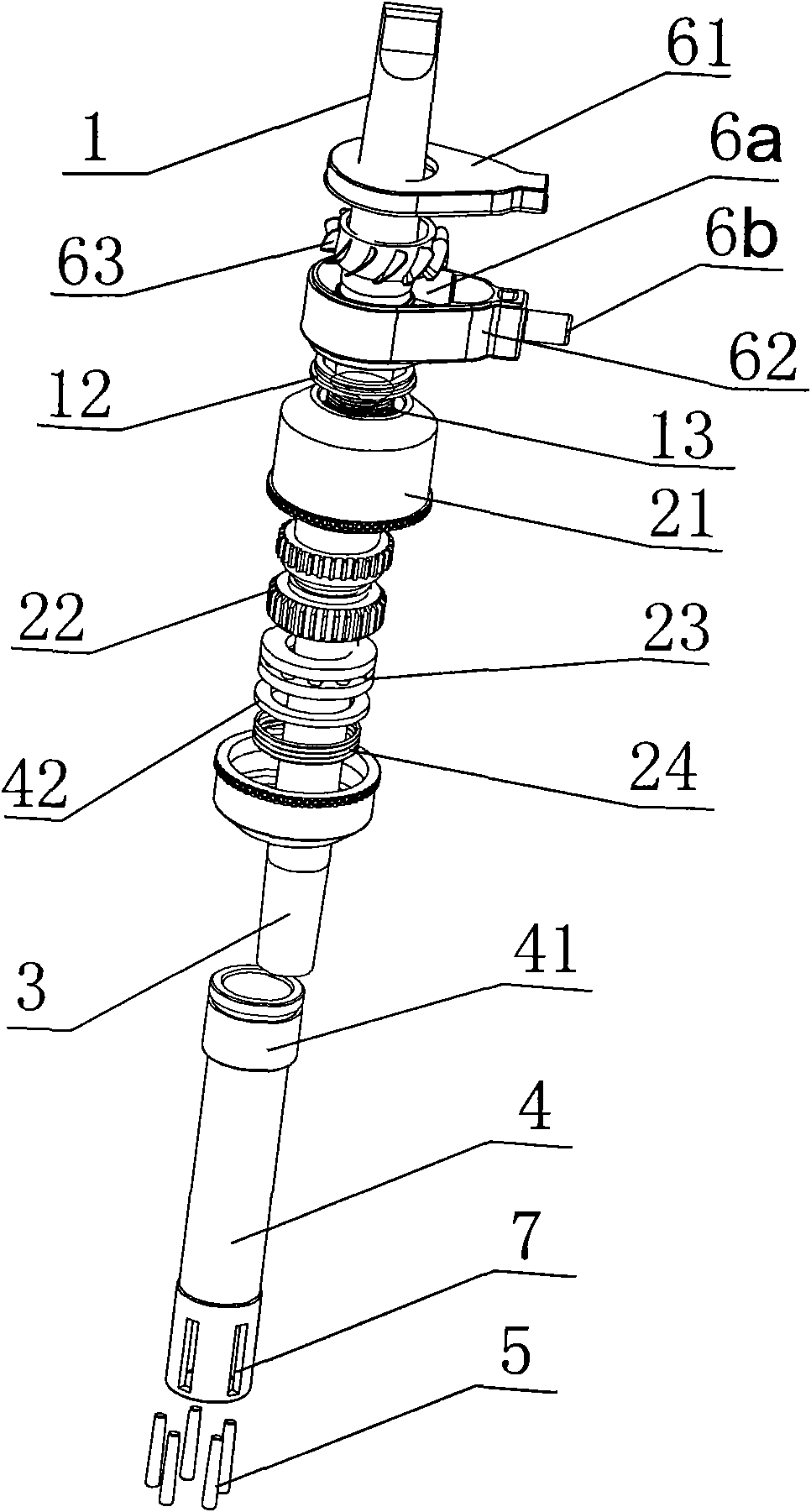

[0017] Figure 1 to Figure 3 Shown is the structural representation of the present invention.

[0018] The reference signs are: connecting part 1, flange body 11, upper gasket 12, adjusting thread 13, connecting part cooling liquid channel 14, size adjusting device 2, size adjusting housing 21, gear set 22, bearing 23, Pressure regulating spring 24, mandrel 3, mandrel coolant channel 31, retaining sleeve 4, assembly flange 41, lower gasket 42, needle roller 5, gear pump 6, working chamber 6a, coolant inlet 6b, Loam cake 61, lower cover 62, spiral worm gear 63, rolling groove 7.

[0019] Such as Figure 1 to Figure 3 As shown, the self-priming internal cooling tool of the present invention includes a connecting part 1 that can be matched with a machine tool, a size adjustment device 2, a mandrel 3, a retaining sleeve 4 and a roller installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com