Polyamic acid resin composite and polyimide film and laminated material prepared from same

A technology of polyamic acid resin and composition, which is applied in the field of polyamic acid resin composition and polyimide film prepared therefrom, and can solve the problems of film embrittlement, film shrinkage, difficult control of reproducibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

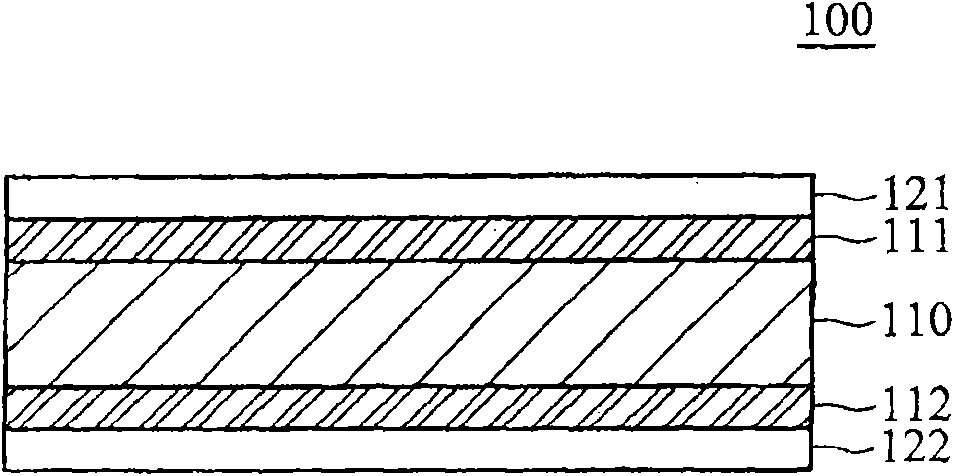

Image

Examples

Synthetic example 1

[0039] Synthesis example 1, have the preparation of the nanoscale silicon dioxide DMAc solution that contains hydroxyl group (-OH) through the surface of modification

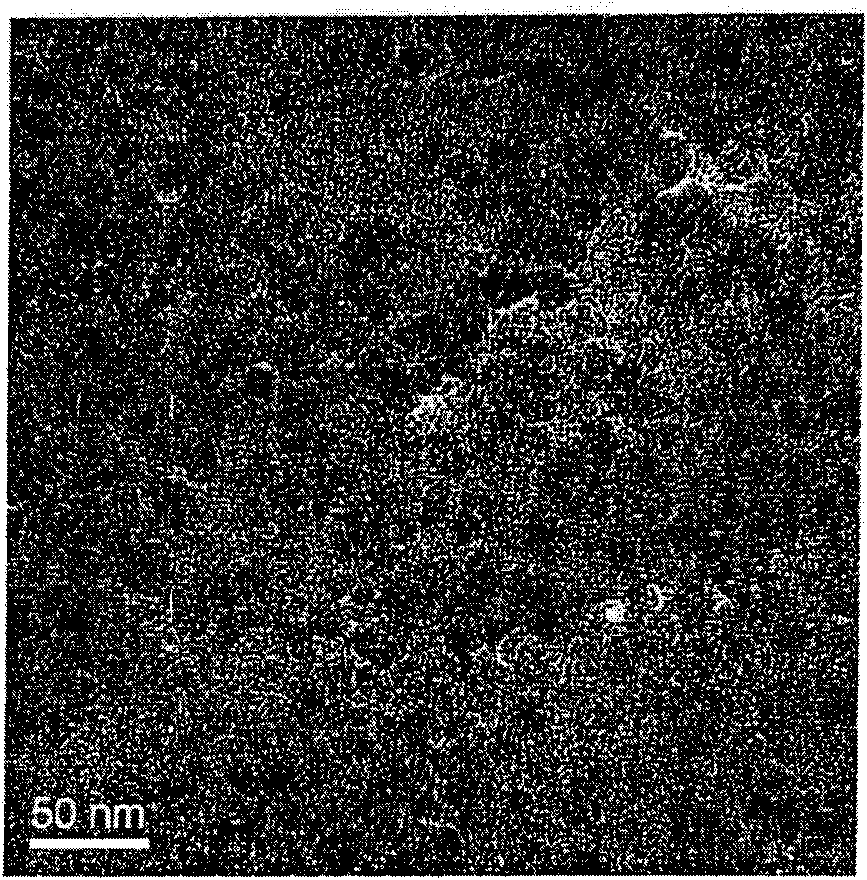

[0040] 100g solid content of 20% has the isopropanol sol (Jingming Chemical Industry) of nano-scale silicon dioxide containing hydroxyl (-OH) on the surface, 1g N-phenyl-3-aminopropyltrimethoxysilane modifier and Add 80g of N,N-dimethylacetamide (DMAc) into a 500ml reaction bottle, react at 40°C for 6 hours, use vacuum distillation to distill 80g of isopropanol and a small amount of water, and replace it with DMAc solution , to obtain a nano-scale silica DMAc solution (DMAc-sol) with a modified surface containing hydroxyl (-OH) with a solid content of 20%, and the average particle diameter of its silica through dynamic light scattering particle size analysis 20nm.

Synthetic example 2

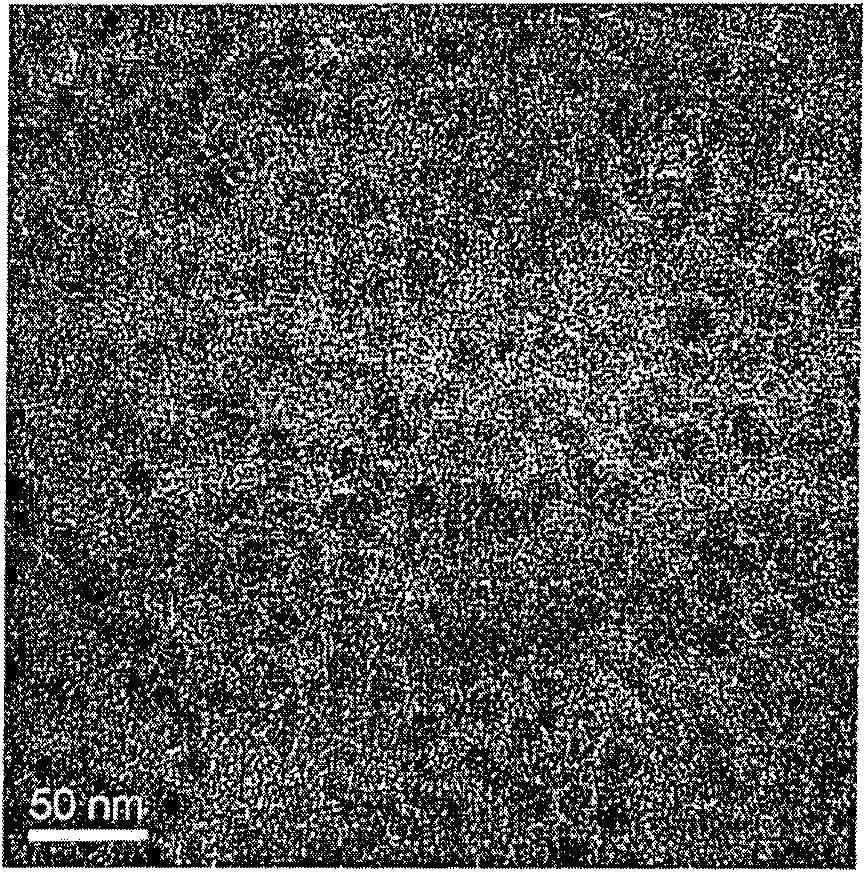

[0042] The isopropanol sol (Jingming Chemical Industry) with the nano-scale silicon dioxide of surface containing hydroxyl (-OH) of 100g solid content 20%, 1g 3-aminopropyltrimethoxysilane modifier and 80g of N, N - Dimethylacetamide (DMAc) was added to a 500ml reaction bottle, and after reacting at 25°C for 6 hours, 80g of isopropanol and a small amount of water were distilled off by vacuum distillation, and replaced with DMAc solution to obtain a solid content of 20 % of nano-scale silicon dioxide DMAc solution (DMAc-sol) with modified surface containing hydroxyl group (-OH), the average particle size of silicon dioxide is 40nm through dynamic light scattering particle size analysis.

Synthetic example 3

[0044] With the isopropanol sol (Jingming chemical industry) of the nano-scale silicon dioxide that has surface containing hydroxyl (-OH) of 100g solid content 20%, 1g 3-propyl isocyanate trimethoxysilane modifier and 80g N, N- Add dimethylacetamide (DMAc) into a 500ml reaction bottle, react at 25°C for 6 hours, use vacuum distillation to distill 80g of isopropanol and a small amount of water, and replace it with DMAc solution to obtain a solid content of 20%. The nano-scale silica DMAc solution (DMAc-sol) with modified surface containing hydroxyl group (-OH) on the surface (DMAc-sol for short), the average particle diameter of silica is 60nm as a result of dynamic light scattering particle size analysis.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com