Belt of rotor blade of wind power plant

A technology for wind rotor blades and wind energy equipment, which is applied to the belt field of wind rotor blades, can solve the problems of expensive belts, and it takes a lot of time to manufacture the main belt, and achieves the effect of avoiding the problem of delamination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In the following drawings, the same or similar components or corresponding parts are always marked with the same reference numerals, so corresponding repeated explanations are omitted.

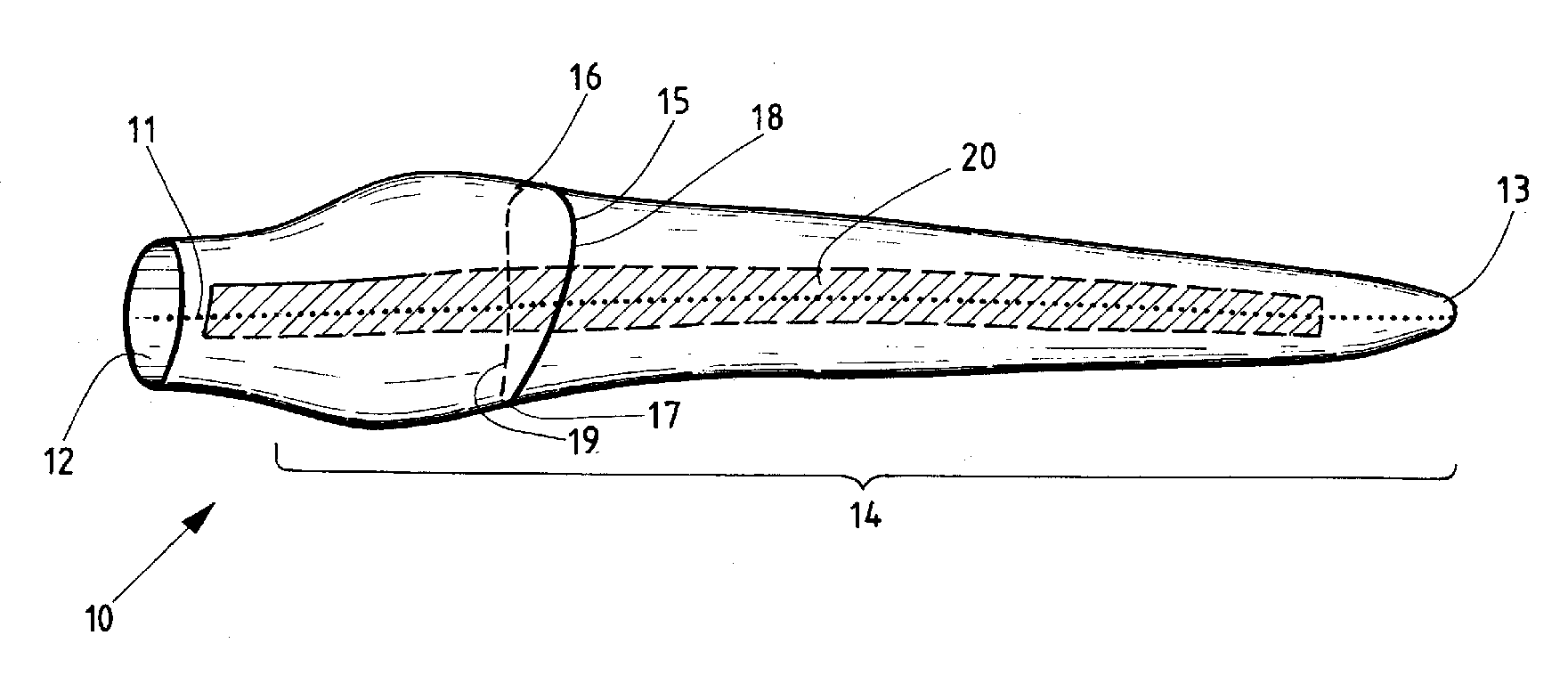

[0031] figure 1 A rotor blade 10 of a wind energy installation is shown schematically. The rotor blade 10 extends along its longitudinal extension 11 from the rotor blade root 12 to the rotor blade tip 13 . In the aerodynamic area 14 there is a cross-sectional structure (Querschnittsprofile) 15 which extends from a structural leading edge 16 (flange) to a structural trailing edge 17 , wherein the structural leading edge 16 and the structural trailing edge 17 make the rotor blade The suction side 18 and the pressure side 19 of 10 are separated from each other.

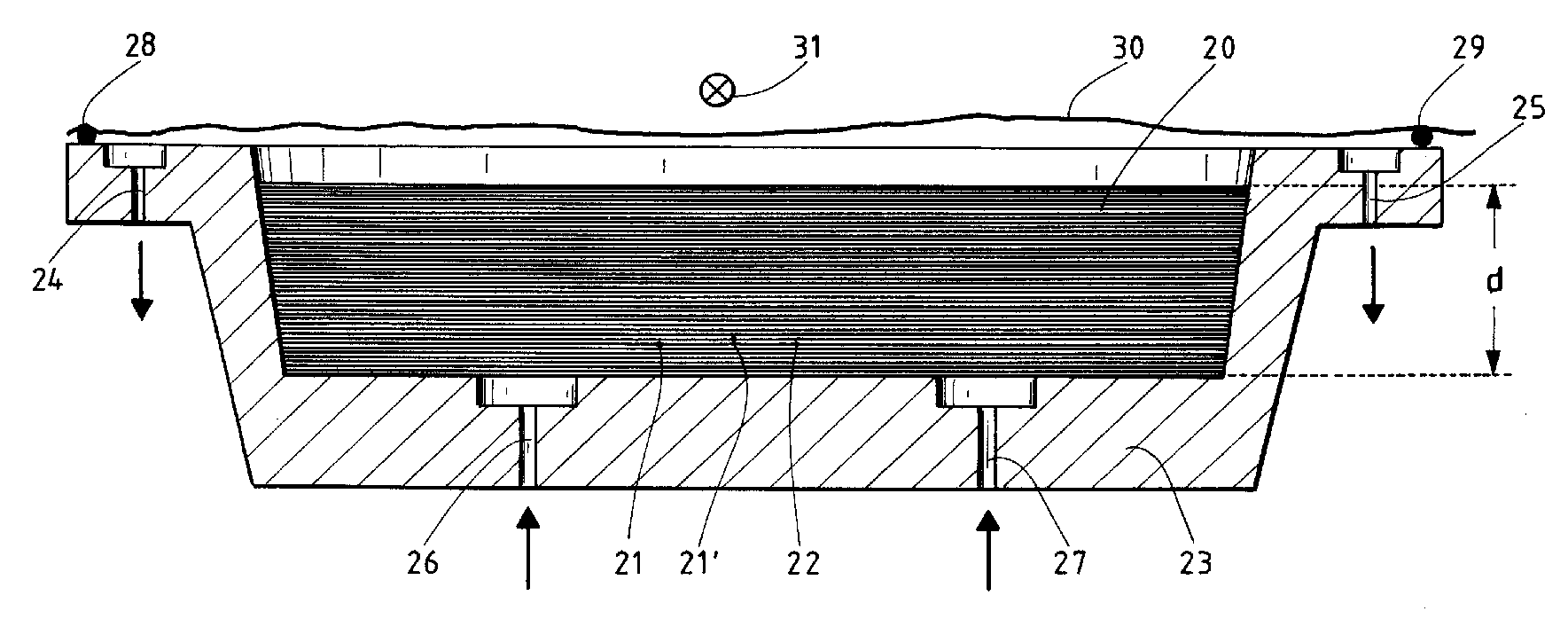

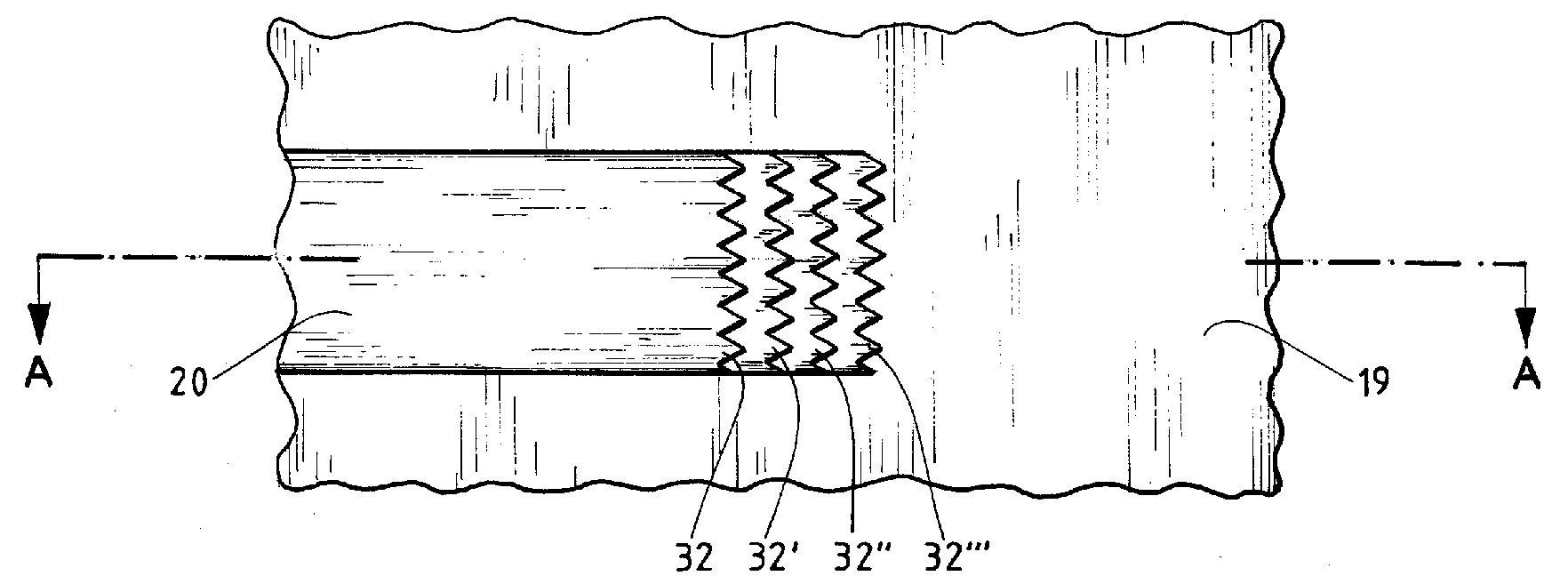

[0032] In order to stabilize the rotor blade 10, a belt 20 is provided, which absorbs most of the forces acting on the rotor blade. The band 20 extends substantially from the rotor blade root 12 to the rotor blade tip 13 . Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com