Supporting and hanging frame stress monitoring system for main steam line of thermal power generating unit

A technology for main steam pipes and thermal power units, which is applied in the direction of measuring the change force of optical properties of materials when they are stressed, and can solve the problems that the stress status of the main steam pipe system of thermal power units cannot be detected and monitored. Achieve accurate and effective monitoring data, avoid accidents, and save maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

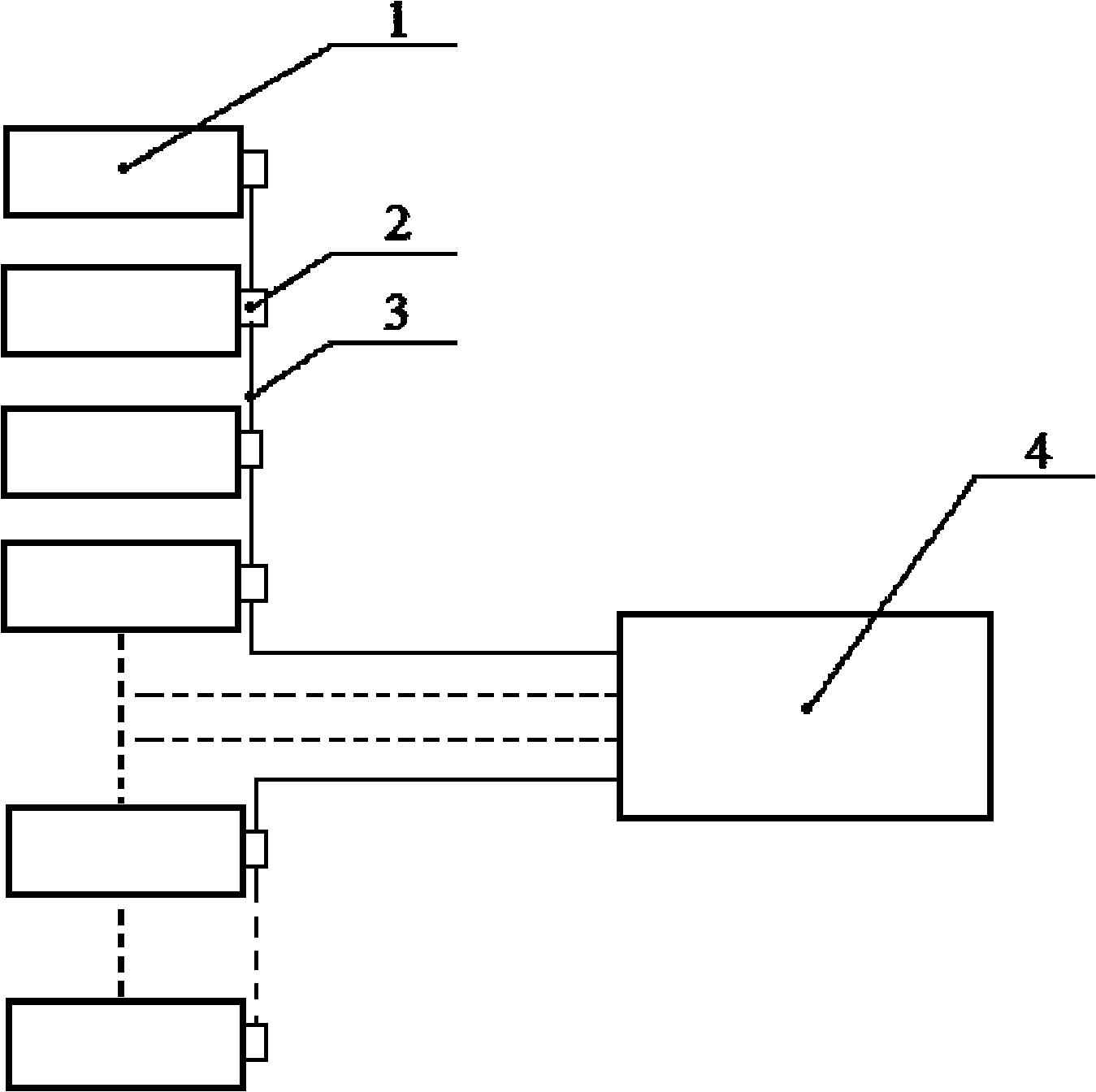

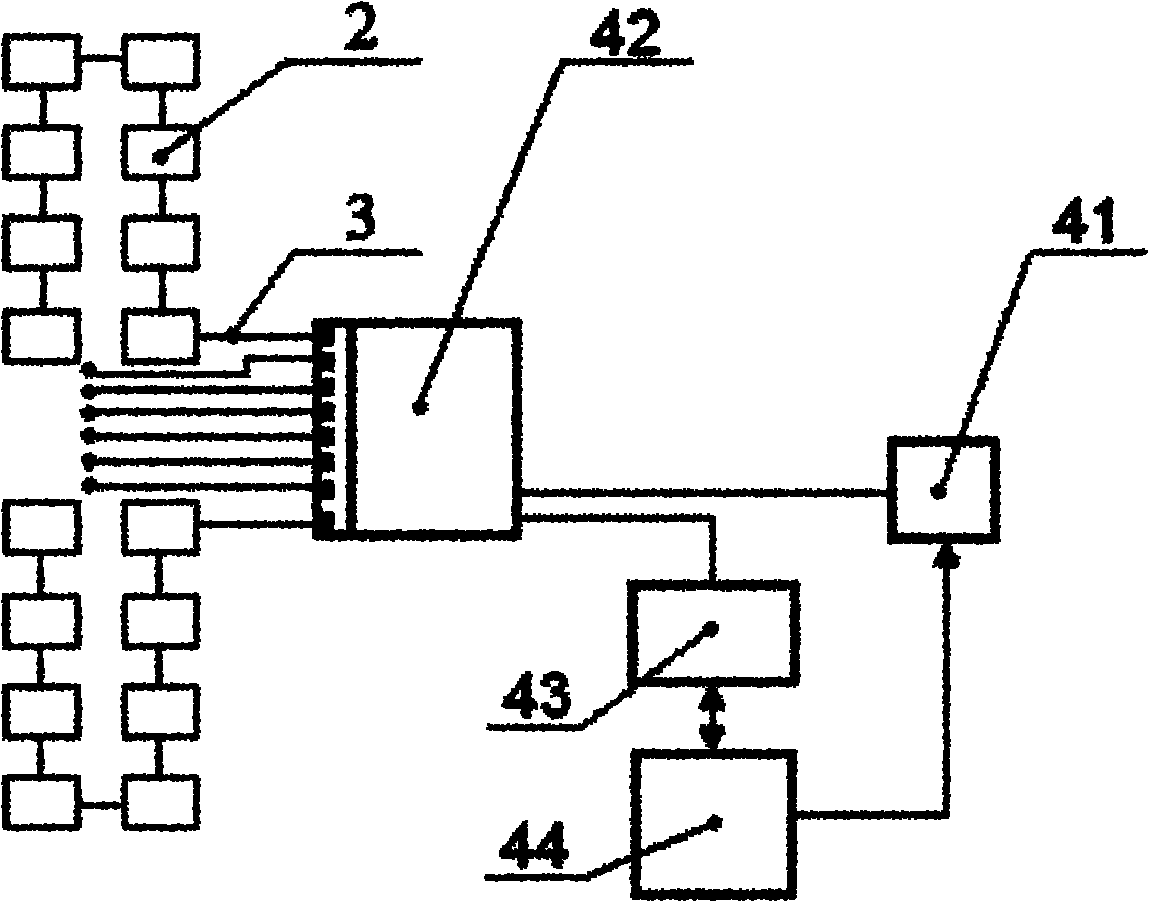

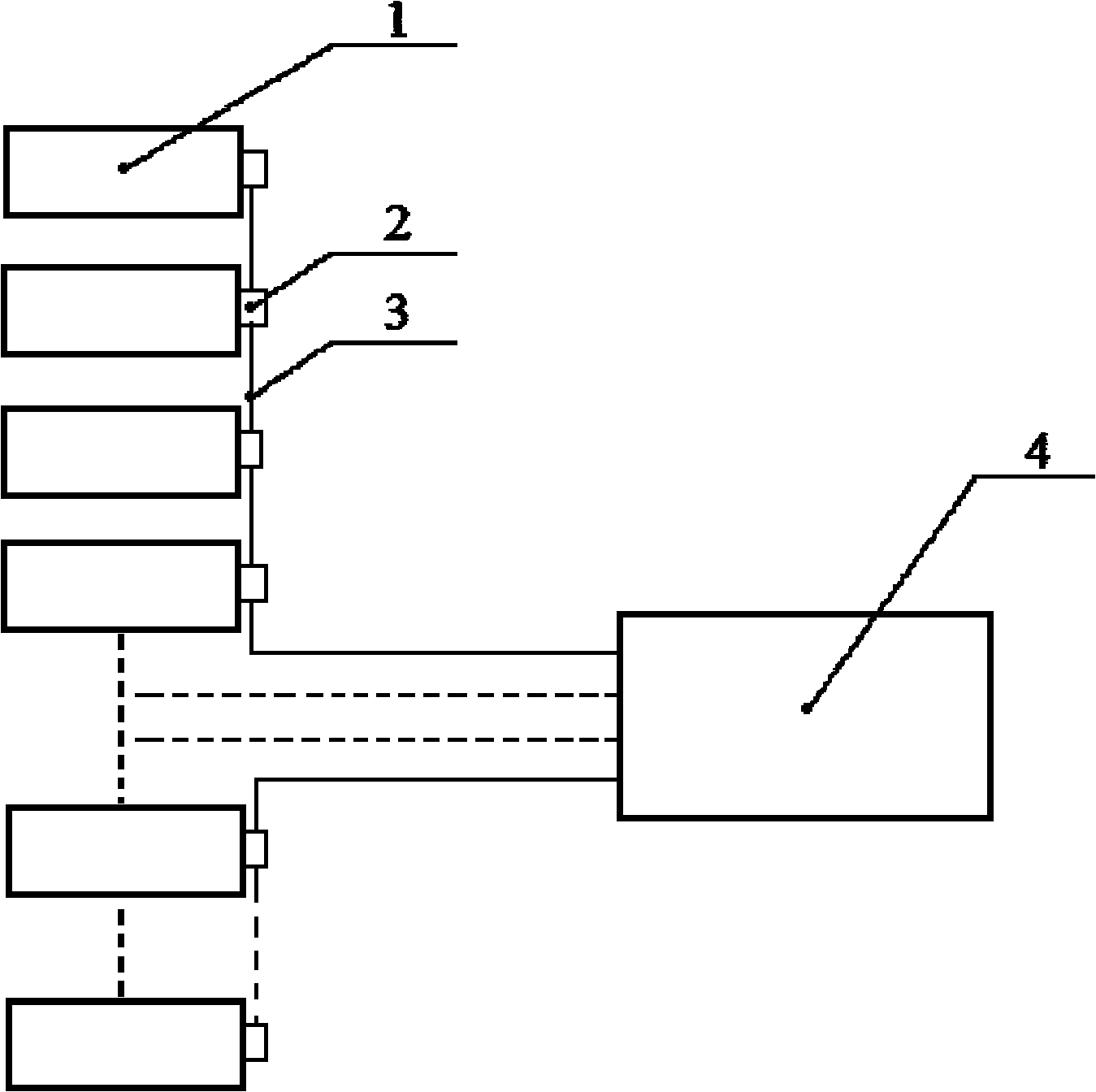

[0024] Such as figure 1 As shown, the present invention discloses a stress monitoring system for the support and hanger of the main steam pipe system of a thermal power unit, including an optical fiber grating stress sensor 2 and an optical fiber sensing demodulation system 4 . The fiber grating stress sensor 2 is installed and fixed on the key part of the main steam pipe support hanger 1 by mounting or welding, and the key part is generally located on the boom of the main steam pipe support hanger 1 . Fiber Bragg grating stress sensor 2 is constructed based on fiber Bragg grating, and the spectral band of fiber Bragg grating covers C band (1525nm~1565nm). The packaging structure of the fiber grating stress sensor 2 will realize the strain conversion, so that the fiber grating can feel the stress and strain, and encode it into the spectrum. The optical fiber grating stress sensor 2 can obtain a strain monitoring range of 0-2% through the desensitization structure processing m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com