Cigarette smoke aerosol testing device

A technology for testing device and cigarette smoke, applied in measurement devices, particle size analysis, scientific instruments, etc., can solve the problems of error, mutual collision, clogging and other problems in test results, and achieve the effect of reducing the probability of particle deposition and reducing easy clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

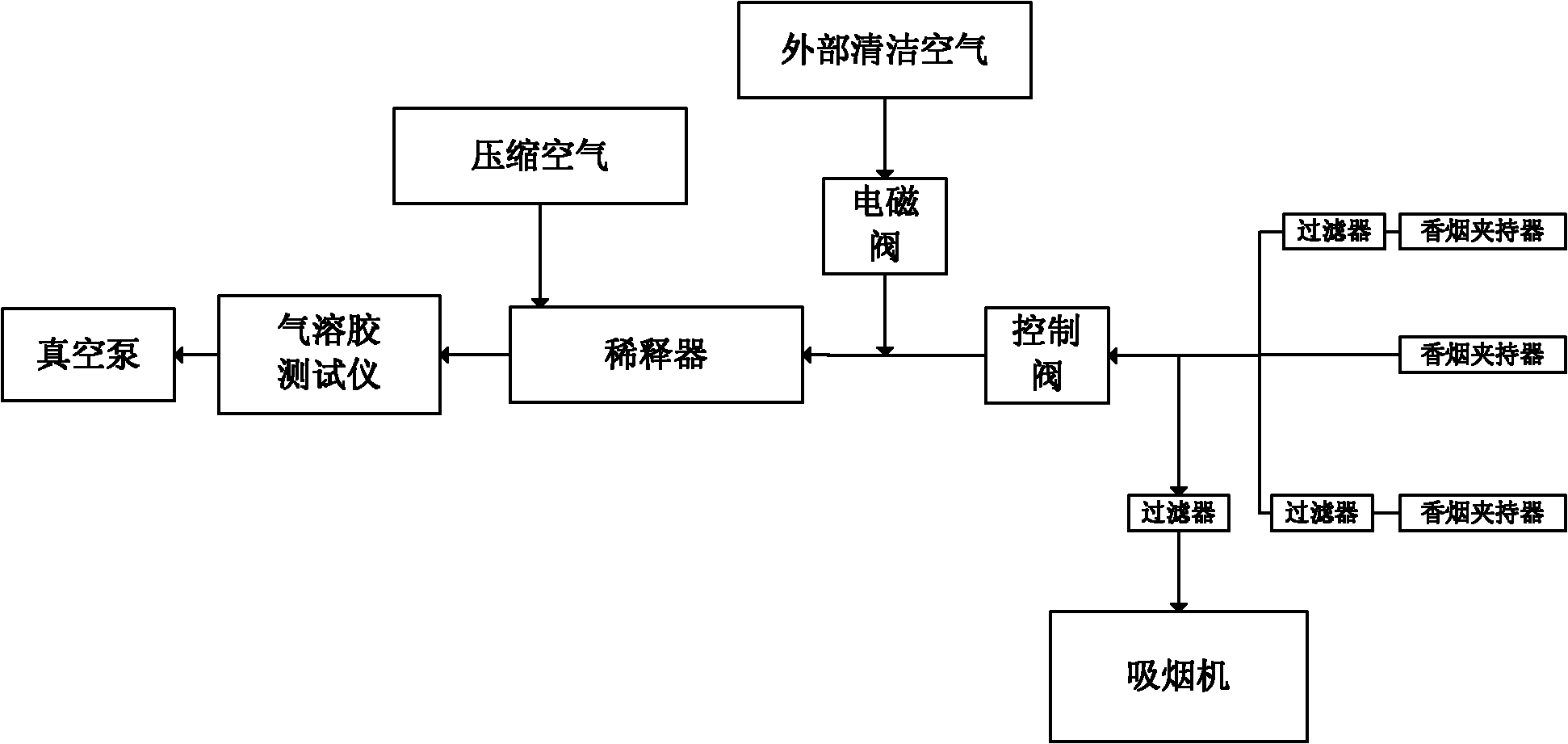

[0021] See figure 1 , figure 2 , image 3 , The structure diagram of the test includes three parts: smoke sampling device, dilution device and aerosol test device. The smoke sampling device includes a cigarette holder, a smoking machine and a control valve connected by a three-way pipe. The number of cigarette holders is three. The three cigarette holders are connected to the three ports of a four-way pipe by a pipe. , Two of the cigarette holders and the four-way pipe are provided with a filter respectively, and the other cigarette holder and the four-way pipe are not provided with a filter. One port of the four-way pipe is connected to the three-way pipe. The smoking machine and There is a filter between the three-way pipes, and the pore size of the filter membrane of the filter is 0.01um. The control valve is connected to the last port of the three-way pipe fitting. The control valve is a pinch valve to solve the problem of easy blockage of ordinary solenoid valves during ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com