Method for improving conductive nozzle of submerged arc automatic welder and welding the conductive nozzle in rotating stand shaft

A submerged arc automatic welding machine and contact tip technology, which is applied in arc welding equipment, electrode accessories, welding rod characteristics, etc., can solve the problem of unreachable welding wire, reduce welding volume, control welding deformation, and reduce welding cost and processing cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Take the turret shaft of the ZZDP1250A planetary gear reducer as an example.

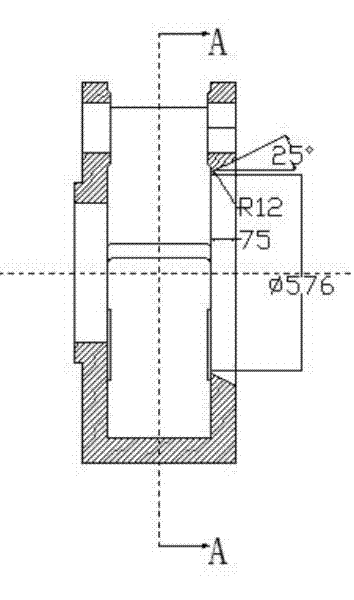

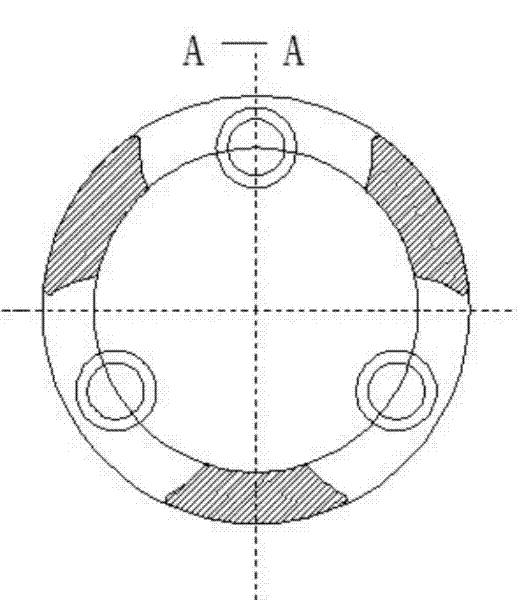

[0030] combine Figure 1-2 , the material of the turret shaft body is ZG35CrMo, the maximum outer diameter is Φ1120mm, and the width is 452mm. The diameter of the positioning hole of the turret shaft body at the single U-shaped annular groove is Φ576mm, and the depth of the U-shaped groove is 79mm (with a machining allowance of 6mm). , U-shaped groove fillet R12mm, U-shaped groove angle 25°, U-shaped groove bottom stop depth 2mm (U-shaped groove bottom stop 2mm+ U-shaped groove design depth 73mm=75mm is the design width) .

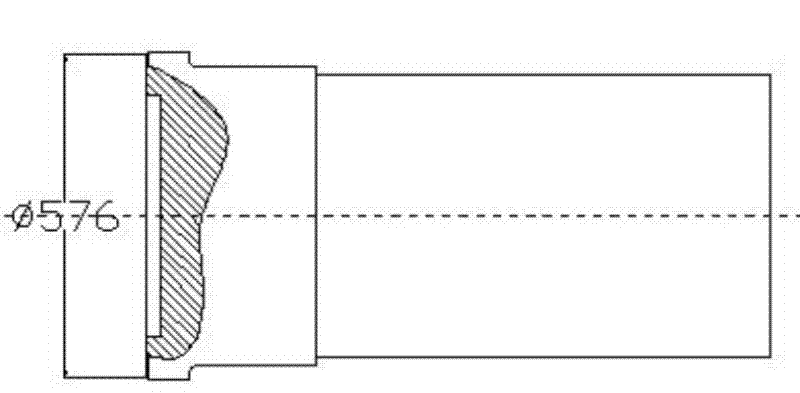

[0031] combine image 3 ,The material of the turret shaft head is 35CrMo, the total length is 1111mm, the diameter of the T-joint is Φ576mm, the width of the T-joint is 79mm (with a machining allowance of 6mm), and the depth of the bottom of the T-joint is 2mm. The machining allowance of the turret shaft body and the turret shaft head is 6mm on one side.

[0032] Befor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com