Welding Process of Aluminum Alloy Roof Beam for Subway

A roof edge beam and welding process technology, applied in the field of aluminum alloy welding, can solve the problems affecting the qualified rate of products, complicated procedures, and high comprehensive cost, and achieve the effects of optimizing welding process parameters, reducing product repair rate, and optimizing welding sequence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

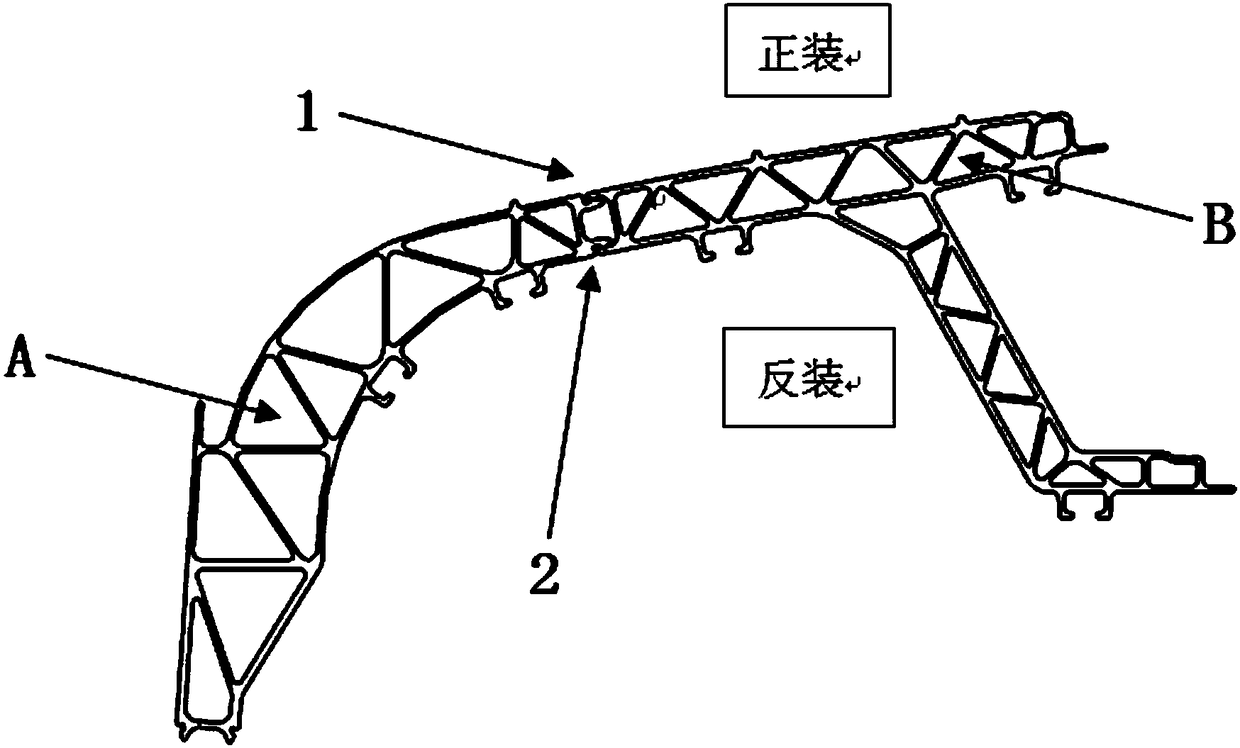

[0028] Such as figure 1 As shown, the aluminum alloy roof side beam for the subway in this embodiment is welded by the side beam profiles A and B.

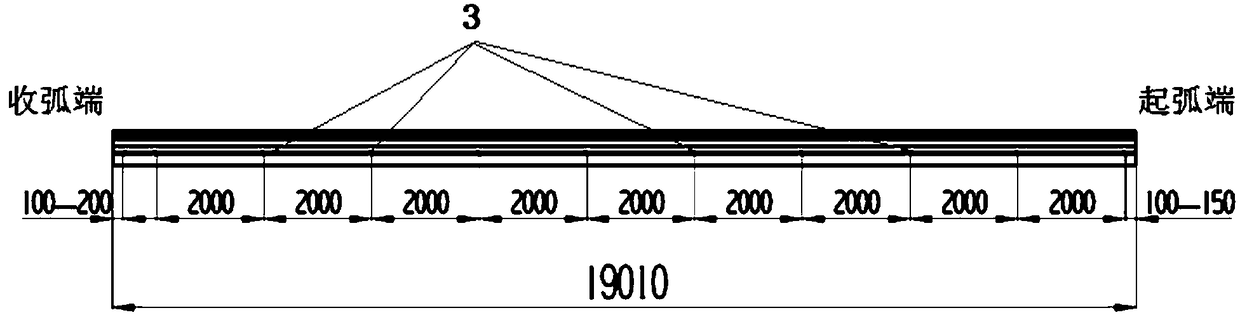

[0029] In this embodiment, the roof side beam is welded in two stages, first by manual spot welding, and then by robot automatic welding, as follows:

[0030] 1), manual spot welding

[0031] 1.1) Formal assembly and assembly: the hollow side beam profiles A and B are installed in the corresponding positions of the special tooling (not shown) and then pressed and fixed;

[0032] 1.2) Front spot fixing: manually spot weld the convex weld 1 of the roof side beam that has been assembled, the welding current is 210A, the weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com