Method for smoothing feed speed of multi-axis numerical control (NC) machining

A technology of feed speed and smoothness, applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems that restrict the surface processing quality of parts, achieve high part surface processing quality and processing efficiency, fast calculation speed, Improvement of processing quality and processing efficiency

Inactive Publication Date: 2011-06-15

HUAZHONG UNIV OF SCI & TECH +1

View PDF2 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In addition, although the constant Cartesian space synthesis speed can be realized by the CNC system, for the continuous high-speed processing of small line segment programs, the completion of the above tasks requires the CNC system to have a strong processing ability, and the general CNC system does not have this ability

There is a contradiction between the joint space and the Cartesian space in terms of speed stability, and the general CNC system cannot make up for this defect, which seriously restricts the improvement of the surface processing quality of parts

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

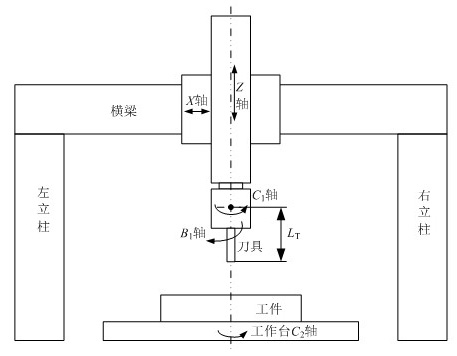

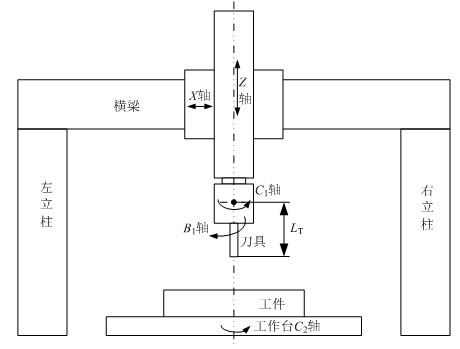

The invention discloses a method for smoothing the feed speed of multi-axis numerical control (NC) machining, which can be applied to multi-axis linkage NC machines with any standard or different structures so as to realize the feed-speed smoothing in the process of machining complicated curved surfaces of the multi-axis linkage NC machines. The method disclosed by the invention comprises the following steps: constructing a kinematics model of a multi-axis linkage NC machine at the post-processing stage of multi-axis NC machining, calculating the generalized motion distance of a cutter by using the Jacobean matrix, and then calculating the nominal feed speed of each row of G codes according to an expected surface cutting speed. In the process of carrying out multi-axis linkage NC machining, the multi-axis linkage NC machine moves according to the nominal feed speed, the actual cutting speed of a cutting blade of the cutter relative to the machined surface of a workpiece is the expected surface cutting speed, and the speed is constant, thereby realizing the feed speed smoothing of the cutter, and significantly improving the surface machining quality of parts.

Description

A Feed Speed Smoothing Method for Multi-Axis NC Machining technical field The invention belongs to the technical field of numerical control machining, and specifically relates to a method for smoothing the feed speed of multi-axis numerical control machining by post-processing, which can be used for standard and heterogeneous multi-axis linkage numerical control metal cutting machine tools and multi-axis linkage numerical control welding machine tools The feed rate is smooth when processing complex surfaces with multi-axis linkage CNC grinding machines. Background technique Multi-axis CNC machining technology can effectively improve machining accuracy, shorten production cycle, reduce labor costs, and improve corporate competitiveness. It is the latest development trend in complex parts processing and is widely used in aviation, aerospace, energy, power, automobiles, molds, etc. Cutting-edge industrial fields. Compared with the traditional three-axis CNC machining, the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23Q15/013

Inventor 杨建中彭芳瑜王宝山黄科杜璇陈吉红唐小琦屈文晓张栋李江威

Owner HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com