Aerating device for oxidizing desulfurated waste liquid

A technology of aeration device and oxidative desulfurization, which is used in oxidation water/sewage treatment, gaseous discharge wastewater treatment, etc., which can solve the problem of easily blocking the aperture of aeration system, high solid content of desulfurization waste liquid, and small particle size of solid particles, etc. problems, to achieve the effect of preventing sedimentation, easy cleaning, and fast mass transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

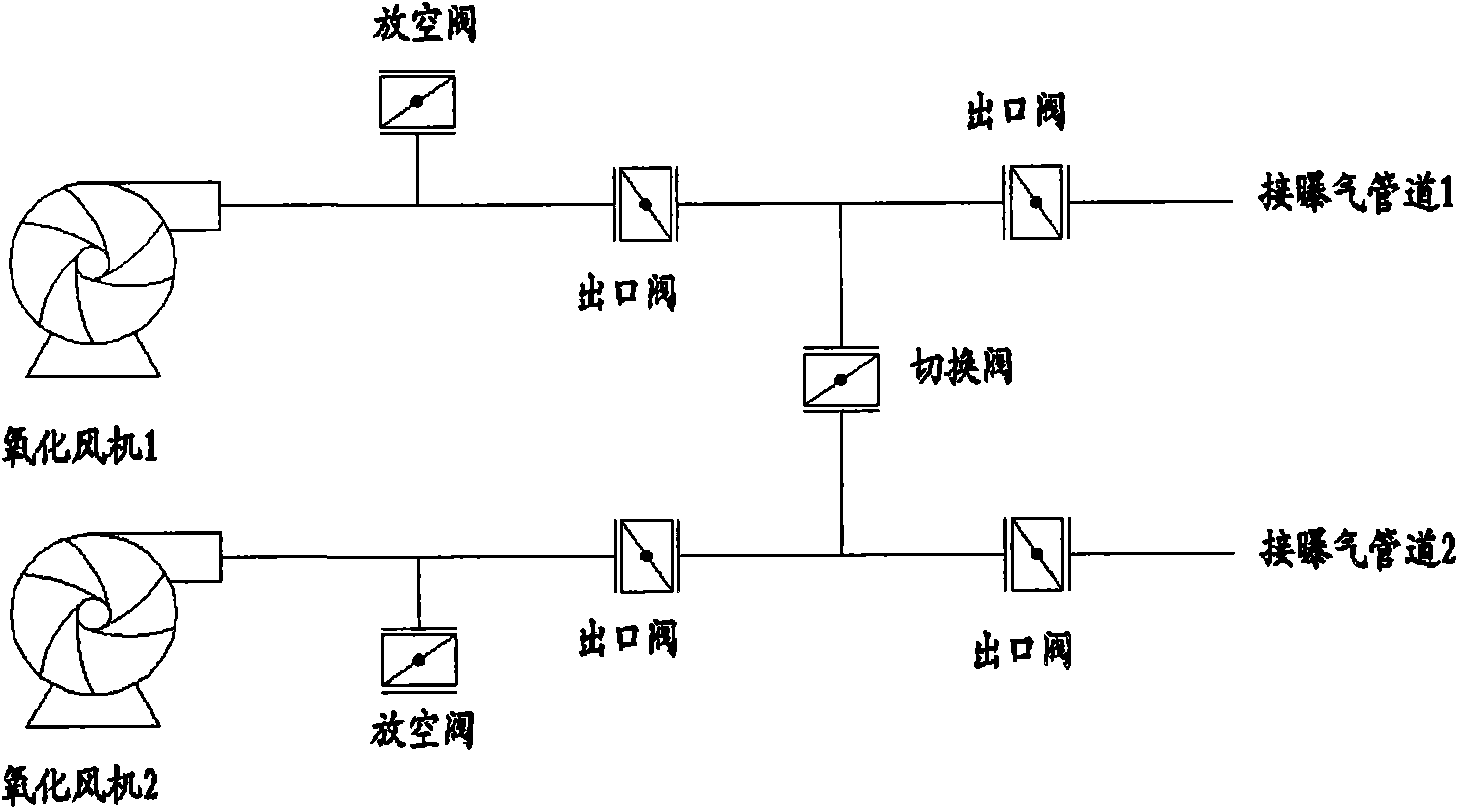

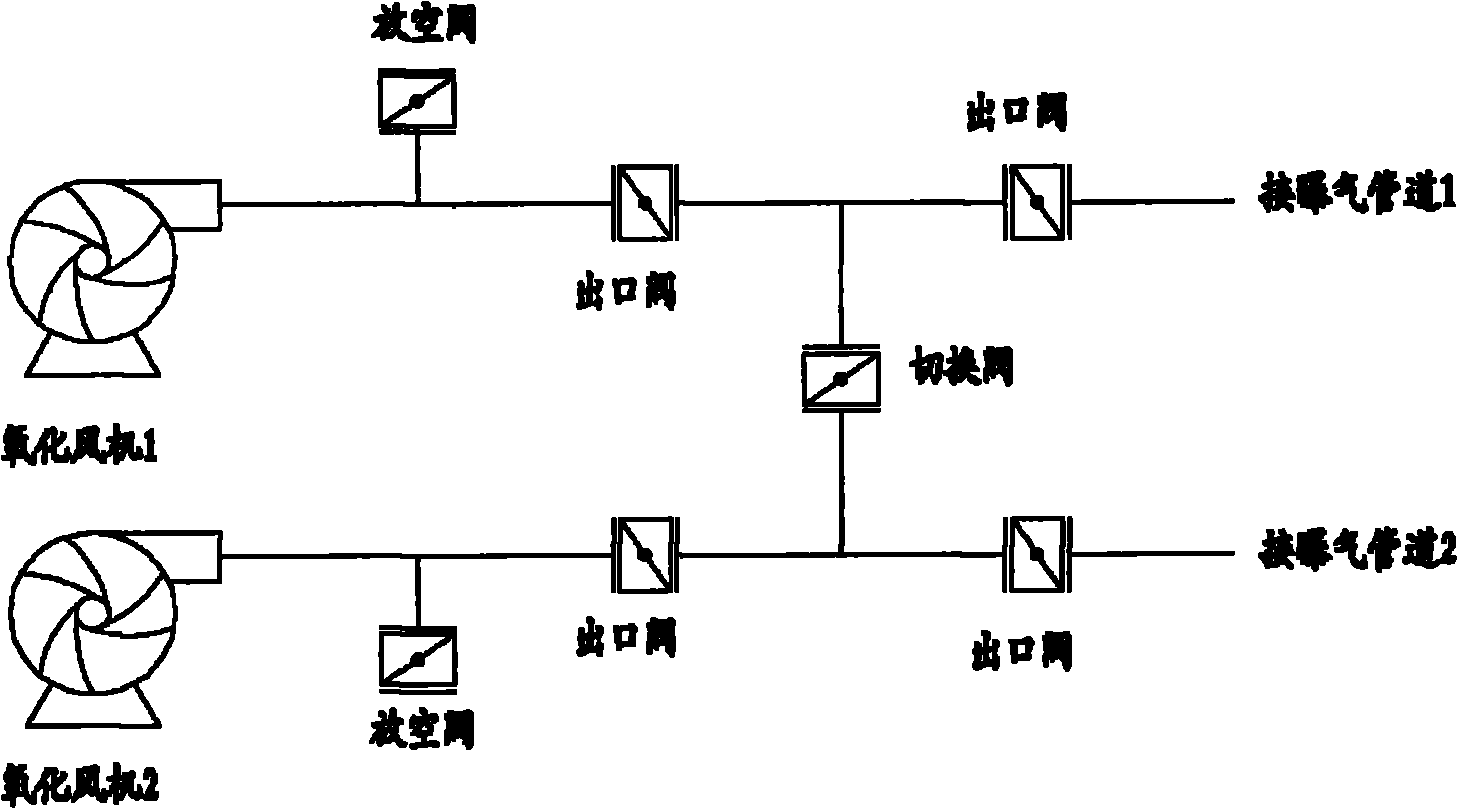

[0012] Depend on figure 1 It can be seen that an aeration device for oxidative desulfurization waste liquid includes an aeration oxidation tank, an oxidation fan, and an aeration pipeline. The aeration oxidation tank is a fixed pool (not shown in the figure), and the oxidation fan includes an upper oxidation fan 1 and a lower oxidation fan. Fan 2, the upper oxidation fan corresponds to the aeration pipe 3 on the upper layer, the outlet pipe is designed as an aeration pipe with a small diameter, which is arranged in the upper layer of the aeration oxidation tank, and the lower oxidation fan corresponds to the aeration pipe 4 on the lower layer, and the outlet pipe is in the tank. The bottom part is designed as an aeration pipe with a slightly larger aperture, which is arranged in the lower layer of the aeration oxidation tank. The outlet pipes of the two oxidation fans are connected. Switching of the gas system.

[0013] In the figure, 6 is the vent valve, which releases the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com