General front axle fall detection device

A detection device, a general-purpose technology, applied in measurement devices, mechanical devices, mechanical measurement devices, etc., can solve the problems of inability to monitor the quality of parts in real time, large initial investment, inaccurate measurement, etc. The effect of reducing adjustment time and improving the yield of qualified products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

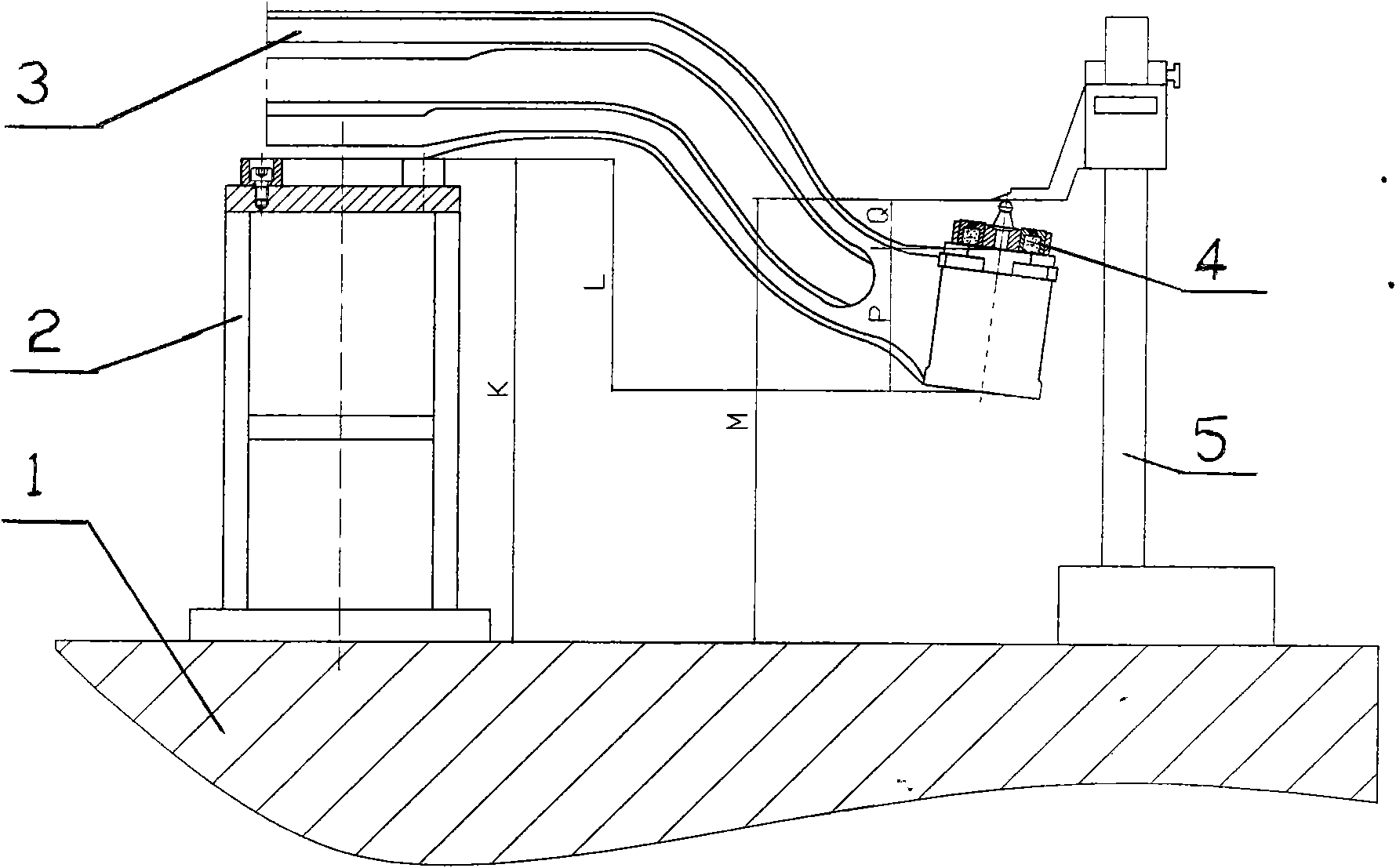

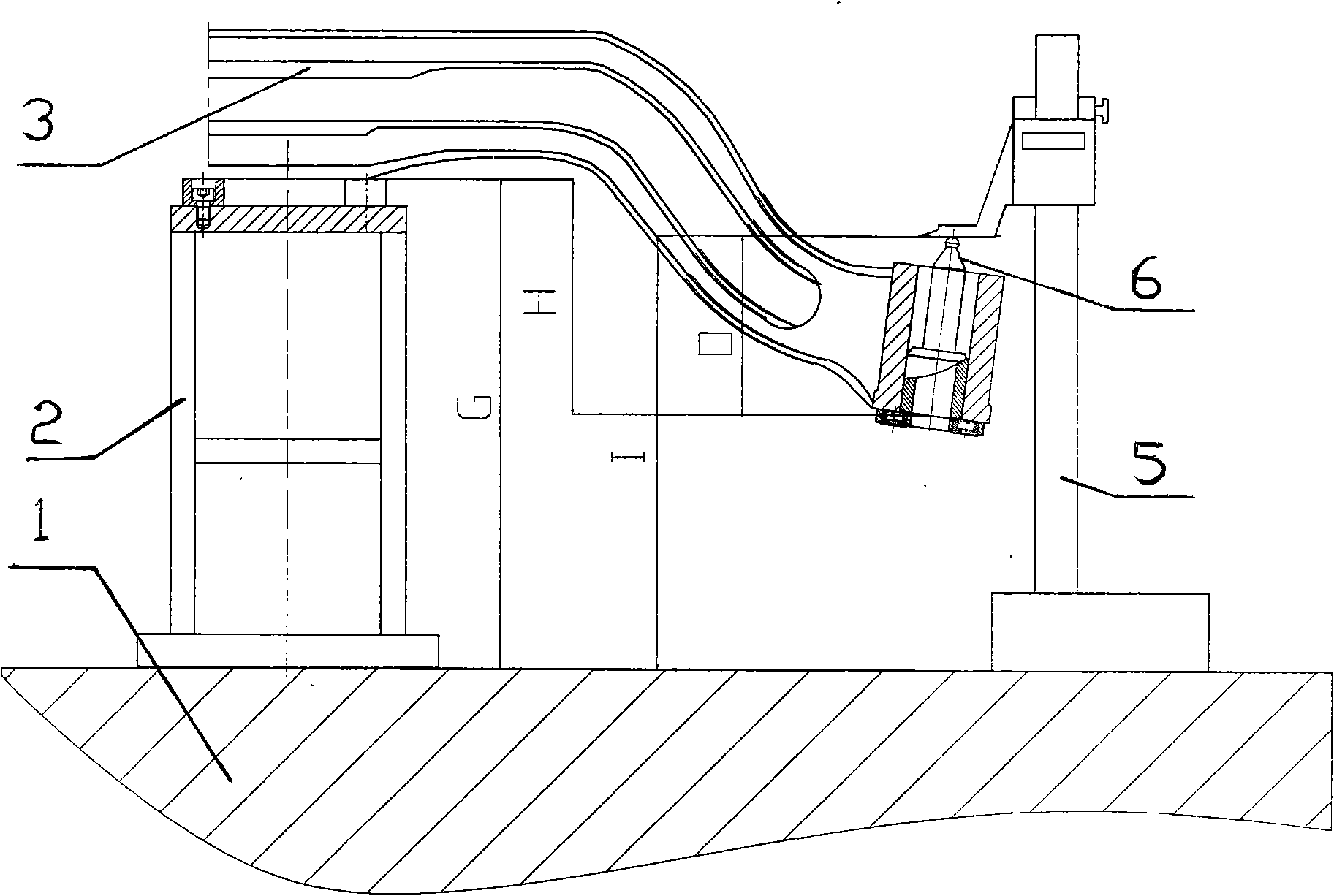

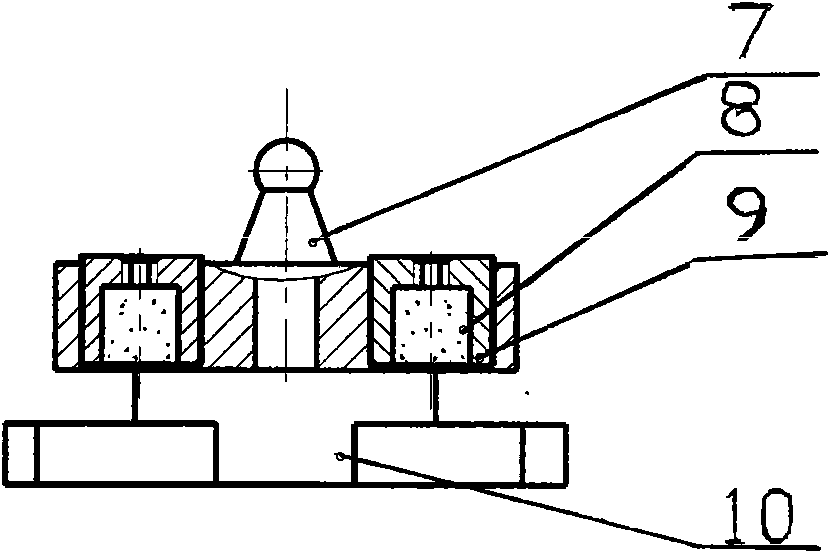

[0020] Such as figure 1 , image 3 , Figure 4 As shown, the inspection table 2 of the rough inspection device is supported on the leaf spring surface of the front axle 3, and the bottoms of the two inspection tables 2 are connected to the flat plate 1 through keys, key grooves and T-shaped screws, so that the distance between the two inspection tables 2 can be adjusted conveniently , to adapt to the detection of different types of front axles; the V-shaped block 10 of the coarse drop gauge 4 is connected with the positioning plate 13 through screws 11 and pins 12, and the two inserts 9 are nuts, which are threaded with the positioning plate 13 and screwed on the positioning plate In the threaded hole of 13, two magnets 8 are set in the insert 9, and the measuring pin 7 is connected with the positioning plate 13 through the pin hole, and the V-shaped block 10 is used for positioning, simulating and extending the center of the fist face after rough milling. During inspection,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com