Identification method for distinguishing iron ore from oxide scale

A technology of iron oxide scale and iron ore, which is applied in the direction of material analysis using wave/particle radiation, material analysis, and material analysis using radiation diffraction. Achieve the effect of saving time, avoiding environmental pollution and ensuring border security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Example 1: Sample composition: Select Indian iron ore (No. 1-37022) as the parent body, mix 1%, 10%, and 50% iron oxide scale into it respectively, mix them thoroughly, and put them in a grinder to grind until they all pass 200 Mesh screen, dried at 105℃ for use.

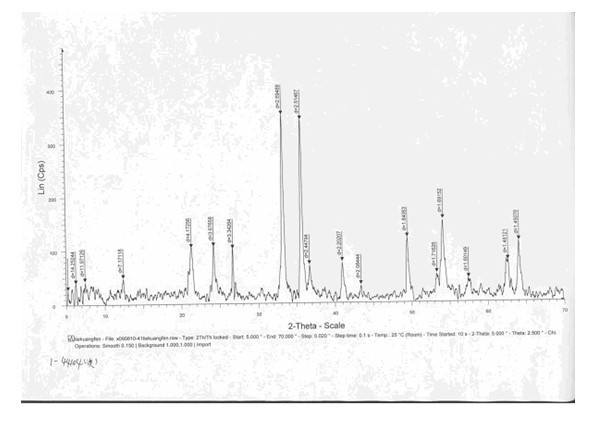

[0067] X-ray diffraction comparison study results: X-ray diffraction spectrum shows that when more than 1% iron oxide scale is mixed in iron ore, there are hematite, magnetite, ferrous oxide, and pure iron peaks, which are in line with the characteristic peaks of iron oxide scale. , But when iron ore is mixed with 1%-10% iron oxide scale, the characteristic peak is not obvious and does not appear as a full spectrum peak. Only when the mixing ratio is greater than or equal to 10% can the full spectrum peak appear and the peak value is significant. Therefore, an accurate judgment can be made for iron ore mixed with more than 10% iron oxide scale, and other methods are needed to assist confirmation for iron ore mi...

Embodiment 2

[0077] Example 2: Identification of doped iron oxide scale in imported iron ore

[0078] The sample is dried first, then prepared, and passed through a 200 mesh screen.

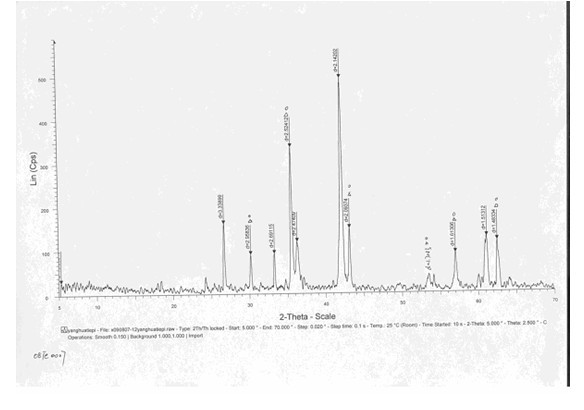

[0079] X-ray diffraction spectrum analysis: X-ray diffraction spectrum analysis of the selected samples found obvious hematite, magnetite, ferrous oxide, and pure iron peaks in the sample, so the sample is judged to be iron oxide scale or iron There is oxide scale in the mine, such as Figure 7 .

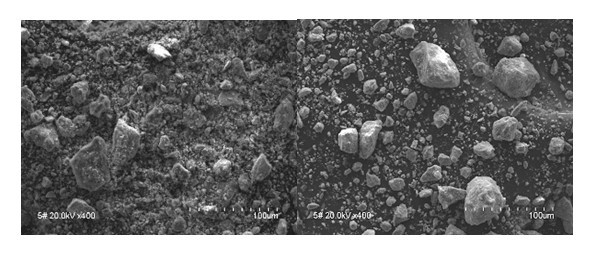

[0080] Analysis by scanning electron microscope: Observing the sample under a scanning electron microscope, it can be seen that there are particles with characteristics of iron ore and particles with obvious characteristics of iron oxide scale, such as Figure 8 .

[0081] Through X-ray diffraction and mineral phase microscope analysis, it can be determined that the sample contains iron oxide scale.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com