Method for identifying properties of heavy metal concentrate, heavy metal calx and tailing

A technology for smelting slag and heavy metals, which is applied in the field of heavy metal inspection to save time, ensure national border safety, and avoid environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] analysis to judge. That is to say, the copper concentrate suspected of being artificially mixed with copper slag cannot be judged only from the results of component analysis. Even if the composition results are completely consistent with the elemental range of copper concentrate in Table 3, it cannot be judged that there is no copper slag mixed in it.

[0084] Table 4 Changes in composition of copper concentrate after mixing smelting slag

[0085]

[0086] X-ray diffraction comparative study results: When more than 10% of residues are mixed into the copper concentrate, the X-ray diffraction spectrum can clearly identify all the characteristic peaks of iron silicate, that is, it can effectively identify the smelting residues mixed in the sample;

[0087] When the copper concentrate is mixed with less than 10% residue, the X-ray diffraction spectrum cannot give all the characteristic peaks of iron silicate. However, according to the X-ray diffraction pattern analysis...

Embodiment 3

[0101] Using X-ray diffraction spectrum analysis: X-ray diffraction spectrum analysis is carried out on the selected samples, and it is found that the selected materials contain a large amount of iron silicate and elemental iron, and have characteristic peaks of iron silicate.

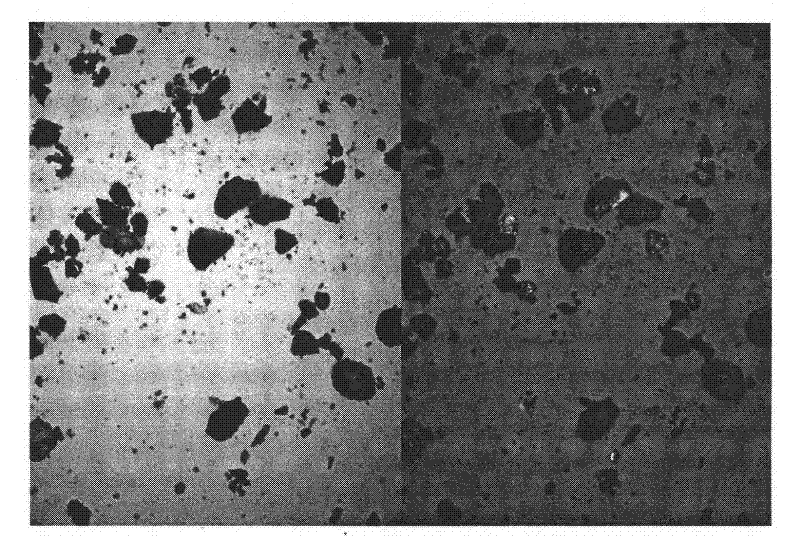

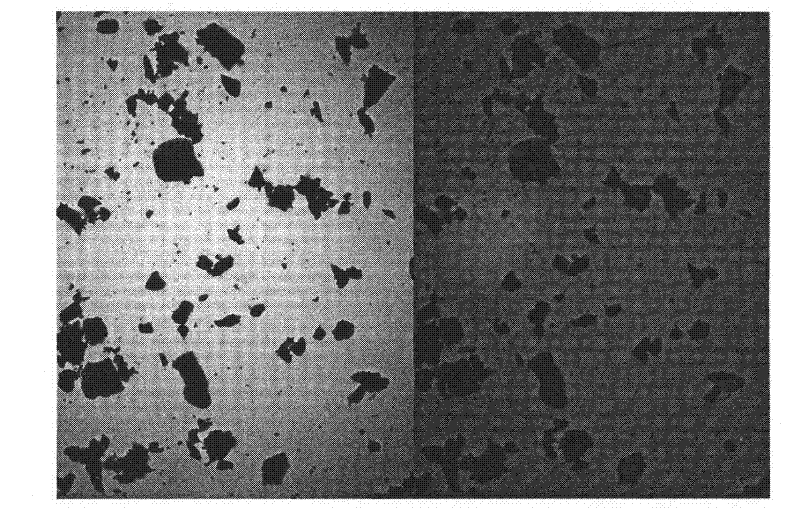

[0102] Mineral phase microscope analysis: observe the selected samples under a mineral phase microscope, and it can be seen that there are obvious molten bead-like objects.

[0103] Through X-ray diffraction and mineral phase microscope analysis, it can be judged that the sample contains smelting slag.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com