Method for detecting components of flavor substance in milk

A technology of flavor substances and detection methods, which is applied in the field of detection of flavor substances in milk, can solve problems affecting the degree of popularity, affecting the economic benefits of dairy farmers and production enterprises, reducing the nutritional value of raw milk, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

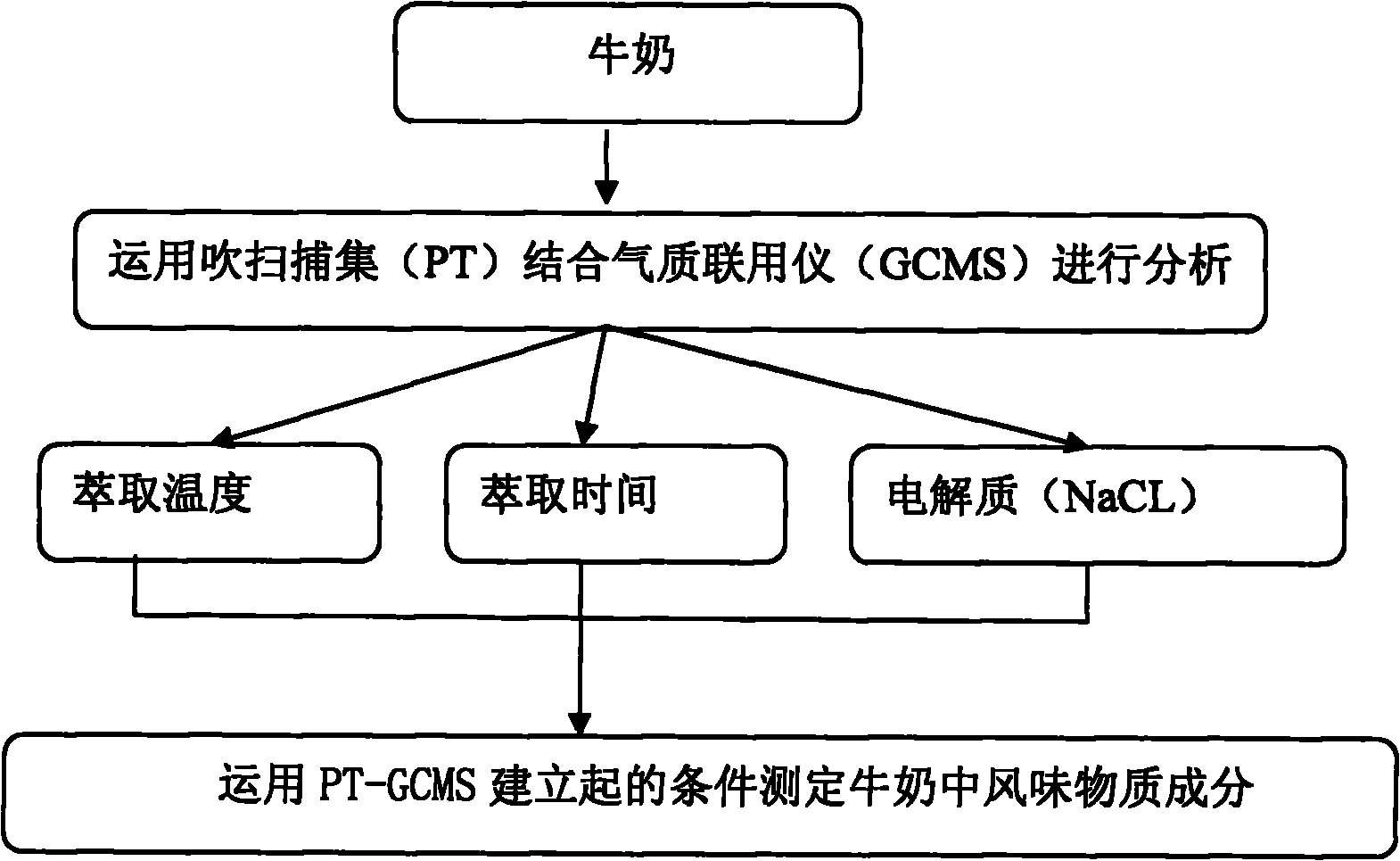

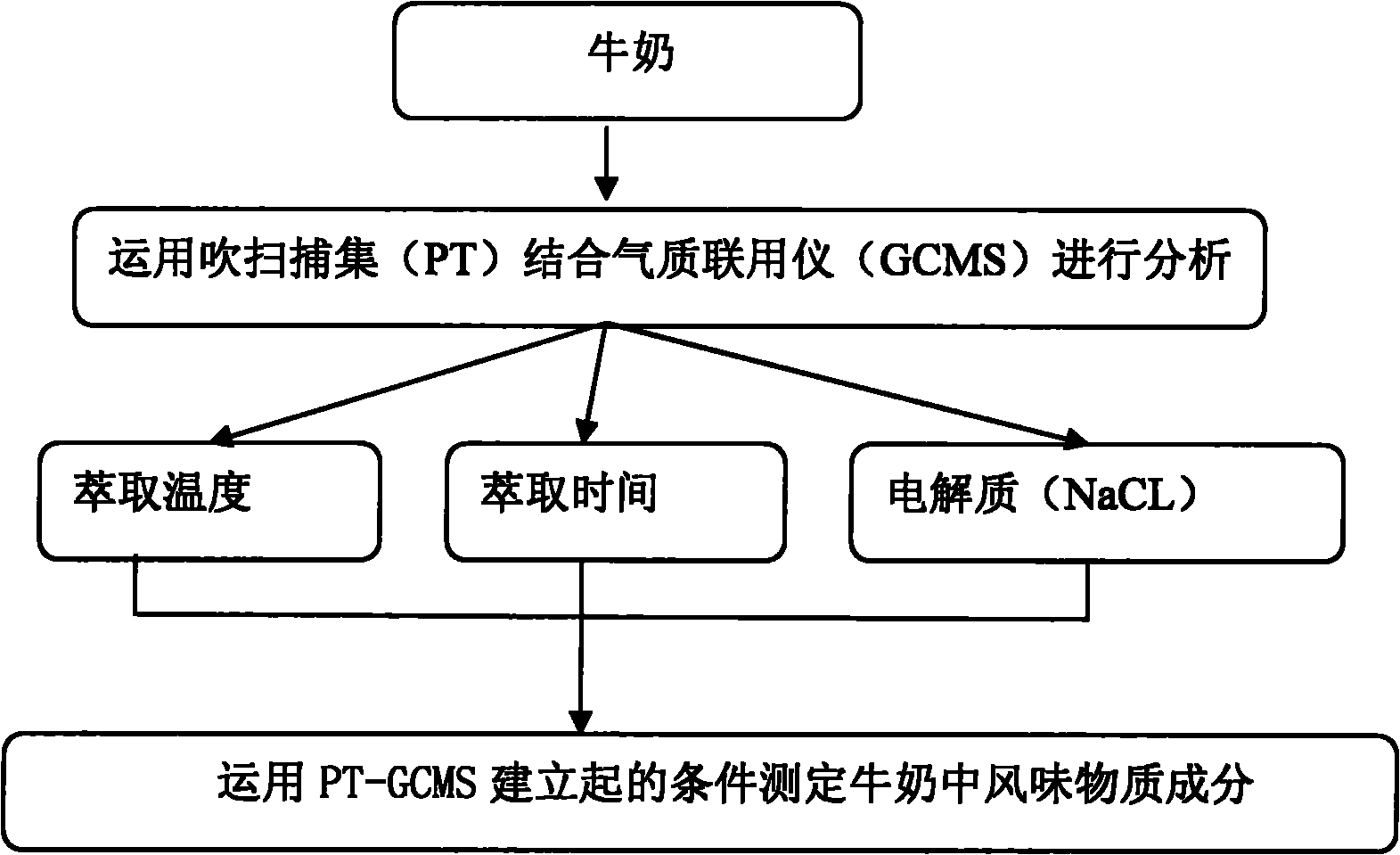

[0011] As shown in Figure 1, this study used purge and trap technology to pre-treat the flavor components in milk, and qualitatively analyzed the flavor components in milk by GC-MS. Compounds were identified against standard mass spectra, thereby determining the composition of flavor components in milk.

[0012] The specific steps are as follows: ①Put 20mL milk sample into a 40mL special sample bottle, add 6.40gNaCl (0.32g / mL), shake well to make it saturated (so that the volatile components are fully blown out), cover and seal; ② Use an automatic purge and trap concentrator to sweep out some volatile flavor substances in the headspace and adsorb them on a capillary trap equipped with Tenax adsorption material; ③ Stir and heat the sample at 40°C and pass it into Helium (40ml / min) purged for 30 minutes, and finally thermal analysis was carried out at 260°C for 2 minutes to decompose the volatile flavor substances, and at the same time start the GC-MS to collect data for automat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com