High definition multimedia interface (HDMI) connector and manufacturing method thereof

A manufacturing method and a technology of connectors, which are applied in connection, fixed connection, parts of connection devices, etc., can solve problems such as the distance between soldering pins of connectors, too close bending, and easy bending of soldering pins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

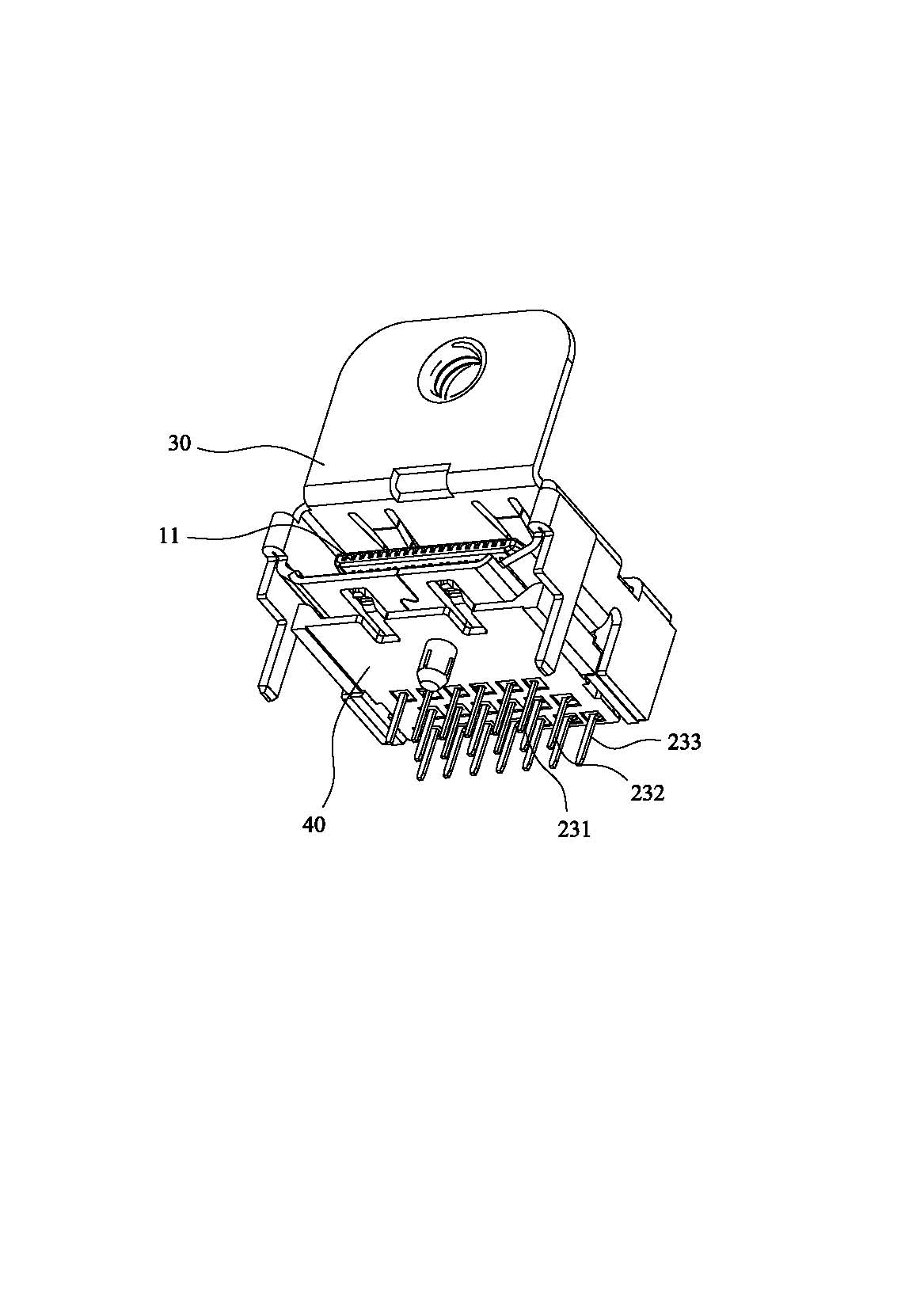

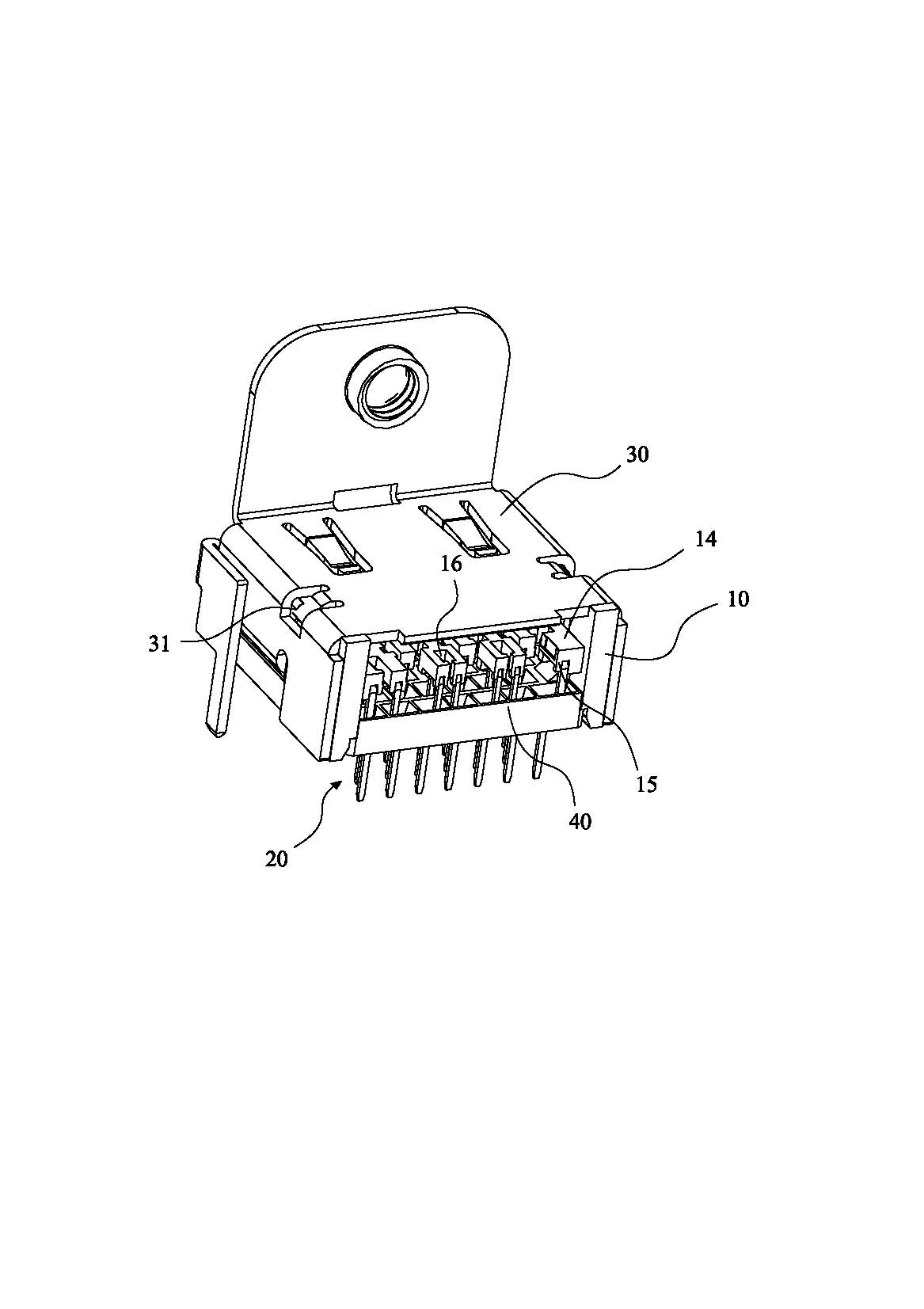

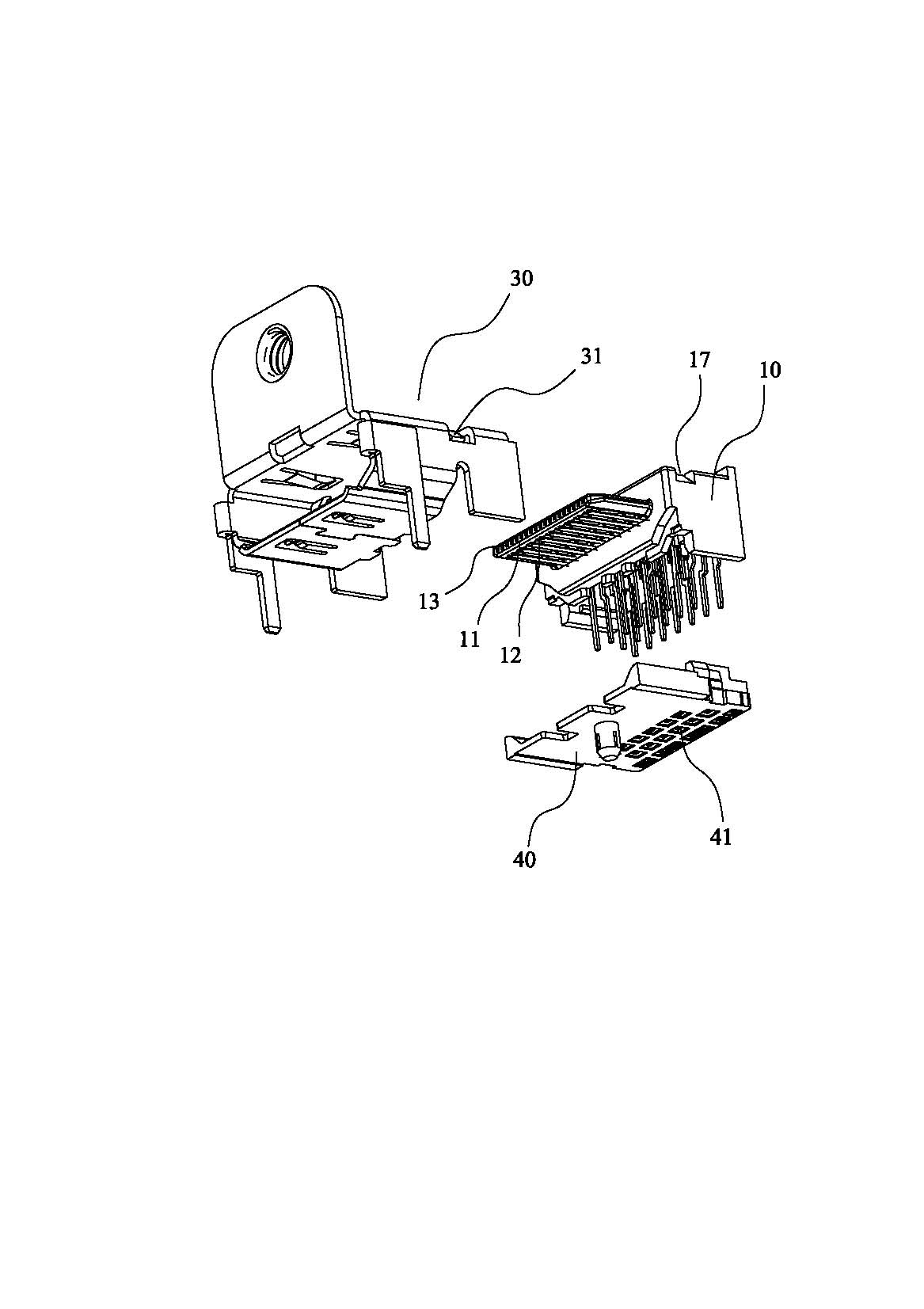

[0045] First, please refer to Figure 1 to Figure 3As shown, it shows the specific structure of the preferred embodiment of the present invention, an HDMI connector, this embodiment is described by taking the 19PIN terminal as an example, including the insulating body 10, the 19PIN conductive terminal 20, the shielding shell 30 and the bottom Cover 40.

[0046] A tongue plate 11 extends from the front of the insulating body 10, and the upper and lower surfaces of the tongue plate 11 are respectively provided with separate grooves 12 between the contact parts of the conductive terminals, so as to prevent the conductive terminals from approaching each other during the injection molding process; the tongues A groove 13 is provided on the front surface of the plate 11, so that the broken part of the conductive terminal sinks into the insulating body, so as to prevent the burr formed at the front end of the conductive terminal from being exposed after the strip is broken; a baffle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com