Short primary DC (direct current) linear motor

A linear motor, short primary technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of poor dynamic characteristics of motors, large flux density fluctuations, low air gap flux density, etc., to achieve small thrust fluctuations, flux density The effect of small fluctuation and high air gap magnetic density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

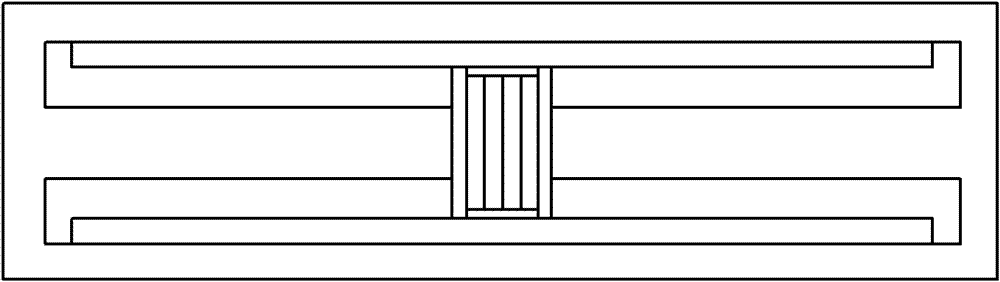

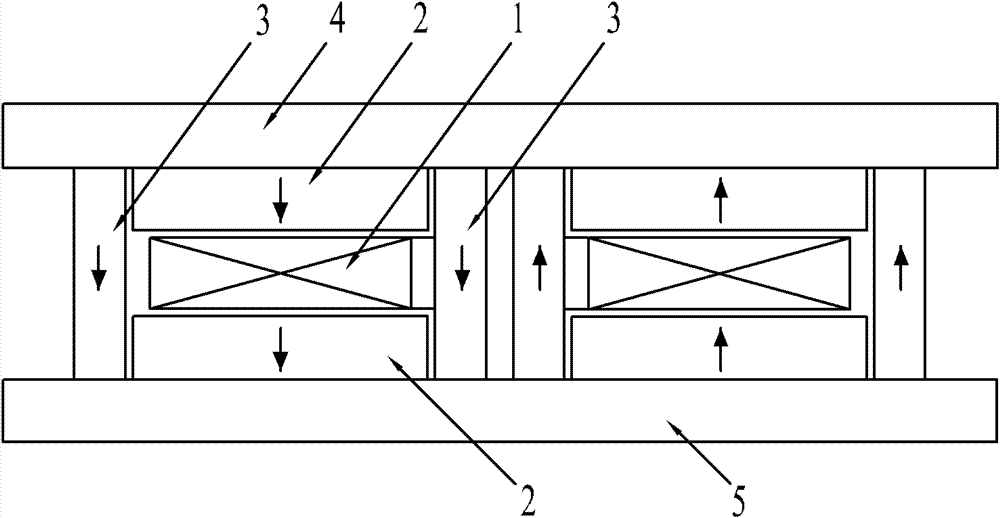

[0014] Specific implementation mode one: combine figure 2 To illustrate this embodiment, it includes a primary and a secondary; an air gap is left between the primary 1 and the secondary;

[0015] The secondary is composed of a plurality of permanent magnet units of the same structure, an upper magnetic yoke 4 and a lower magnetic yoke 5;

[0016] Each permanent magnet unit is composed of two main permanent magnets 2 and two elongated auxiliary permanent magnets 3;

[0017] The two main permanent magnets 2 are planar permanent magnets magnetized in parallel; one main permanent magnet 2 is fixedly arranged on the lower surface of the upper magnetic yoke 4; the other main permanent magnet 2 is fixedly arranged on the lower surface of the lower magnetic yoke 5 on the upper surface;

[0018] The installation positions of the two main permanent magnets 2 correspond to each other;

[0019] The two strip-shaped auxiliary permanent magnets 3 are respectively installed at the two e...

specific Embodiment approach 2

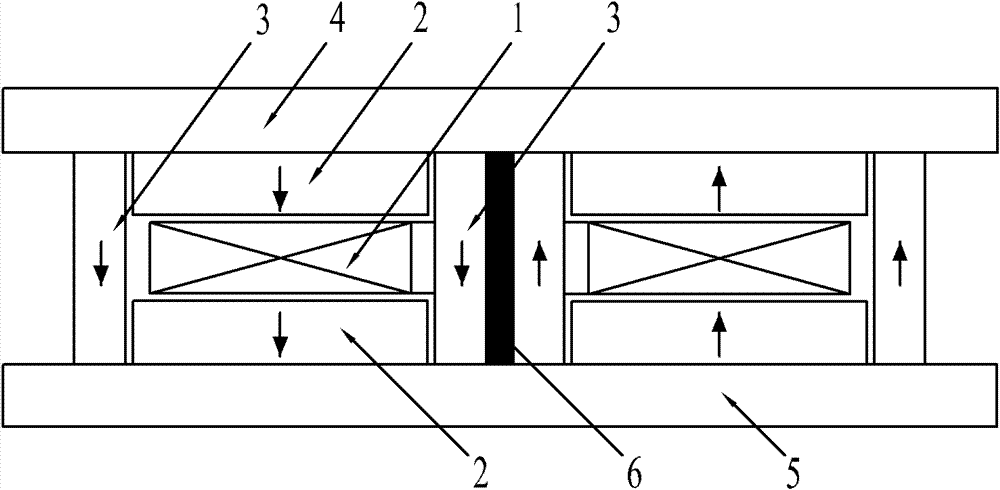

[0024] Specific implementation mode two: combination image 3 Describe this embodiment, the difference between this embodiment and the specific embodiment is that it also increases a plurality of reinforcing plates 6; the reinforcing plate 6 adopts a magnetic material reinforcing plate; Between adjacent permanent magnet units. Other compositions and connection methods are the same as those in Embodiment 1.

specific Embodiment approach 3

[0025] Specific implementation mode three: combination Figure 4 Illustrate this embodiment, it includes primary and secondary; There is an air gap between the primary 1 and the secondary; The secondary consists of a plurality of permanent magnet units of the same structure, an upper magnetic yoke 4 and a lower magnetic yoke 5 composition;

[0026] Each permanent magnet unit is composed of four main permanent magnets 2, two elongated auxiliary permanent magnets 3 and two block auxiliary permanent magnets 7;

[0027] The four main permanent magnets 2 are planar permanent magnets magnetized in parallel;

[0028] The four main permanent magnets 2 are equally divided into an upper main permanent magnet group and a lower main permanent magnet group; the upper main permanent magnet group is fixedly installed on the lower surface of the upper magnetic yoke 4; the lower main permanent magnet group is fixed Installed on the upper surface of the lower magnetic yoke 5; the installation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com