Method for producing coconut-taste coconut oil powdered grease

A technology of powdered oil and production method, applied in the direction of edible oil/fat, food science, application, etc., can solve the problems of inconvenient food processing, easy oxidative deterioration, poor fluidity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

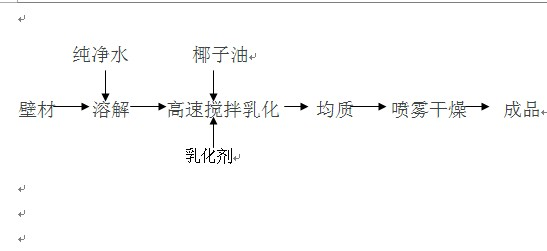

Method used

Image

Examples

Embodiment Construction

[0011] 1. While stirring, add 50Kg of microporous starch, 60Kg of maltodextrin, 16.7Kg of gum arabic, and 5.4Kg of sucrose lipid into 800Kg of water and stir to dissolve.

[0012] 2. Add 1.3 Kg of distilled monoglyceride to 200Kg of edible coconut oil, and stir to dissolve.

[0013] 3. Mix the above two solutions, stir and emulsify at 85°C for 30 minutes.

[0014] 4. Homogenize the emulsion twice with a pressure of 40Mpa on the homogenizer.

[0015] 5. Spray-dry the emulsion on a spray dryer with an inlet temperature of 190°C and an outlet temperature of 95°C to obtain coconut oil powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com