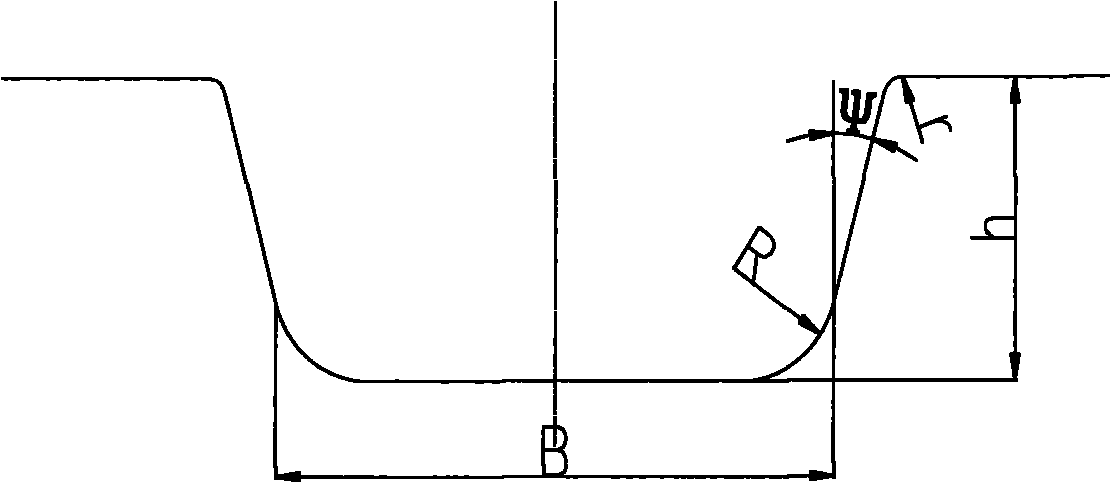

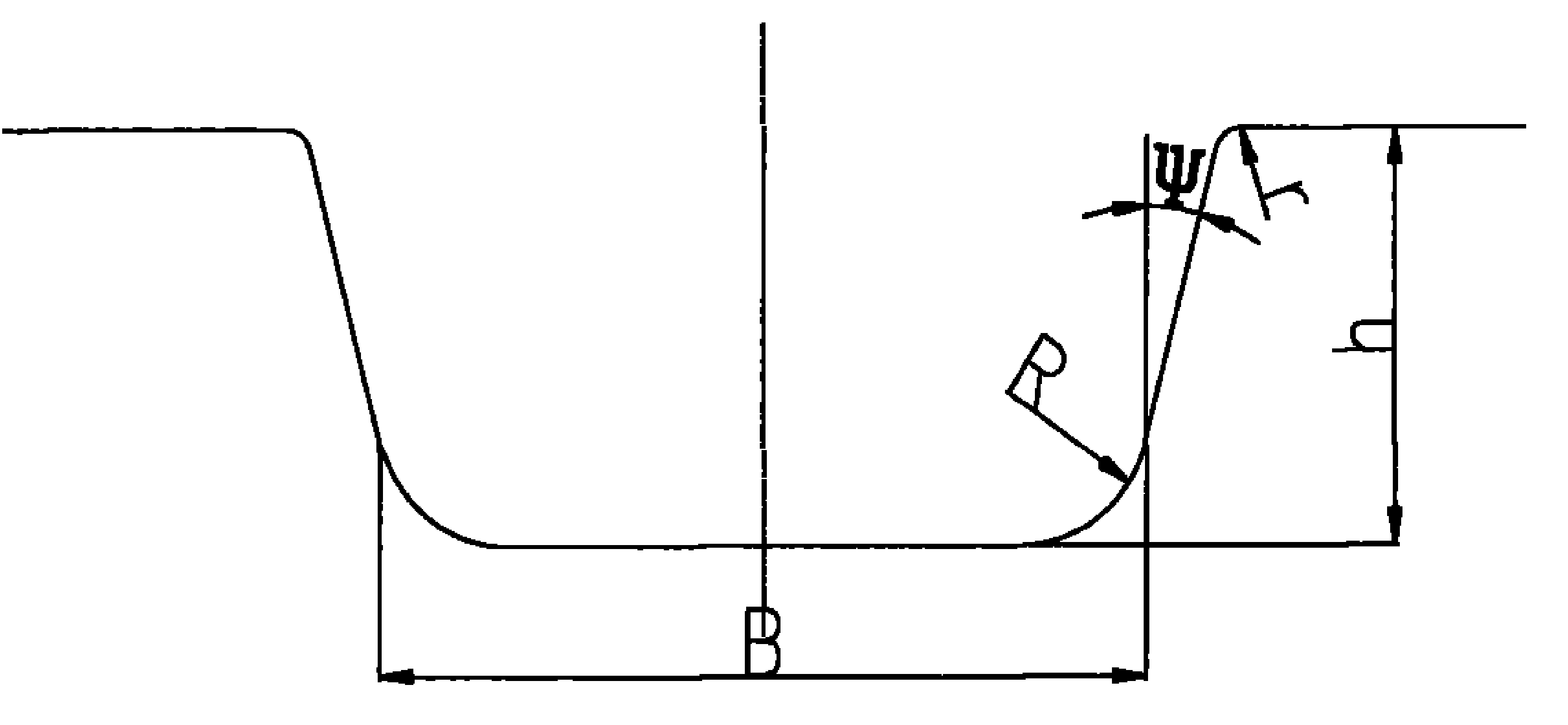

Production method for eliminating edge defects of hot rolled strip steel

A production method and technology of hot-rolled strip steel, applied in metal rolling and other directions, can solve problems such as edge defects, achieve the effects of improving plasticity, saving energy, and eliminating edge defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

[0039] Example 2 The casting speed of the continuous casting machine is 1.75m / min, and the secondary cooling water volume of the continuous casting machine is 232.88m 3 / h, close the two side nozzles at the end of the horizontal section of the continuous casting machine.

example 3

[0040] Example 3 The casting speed of the continuous casting machine is 1.75m / min, and the secondary cooling water volume of the continuous casting machine is 228.68m 3 / h, close the two side nozzles at the end of the horizontal section of the continuous casting machine.

[0041] 5. Heating process

[0042]The heating production process corresponding to the components of the examples is as follows: the continuous casting slab is directly hot-charged, the heating temperature of the continuous casting slab in Example 1, Example 2, and Example 3 is 1150-1300 ° C, the example 1 stays in the heating furnace for 100 minutes, and the example 2 and Example 3 Stay in the heating furnace for 120min.

[0043] 6. Hot rolling rough rolling process

[0044] According to the corresponding hot rolling rough rolling production process of embodiment composition, the vertical roll gap value and the side pressure of example 1 are: the first pass vertical roll gap 1508mm, side pressure 17mm; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com