Device for processing longhole

A processing device and deep hole technology, applied in the direction of feeding device, metal processing, automatic control device, etc., can solve the problems of tool damage, unreliable structure, high processing scrap rate, etc., to improve processing accuracy, work efficiency, and dynamic The effect of stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Refer to the attached figure 1 In today's mechanical structure design, if you want to achieve the best use effect, you must design around a processing technology as the core, so that all the functions of the device serve the core of the process to achieve good results.

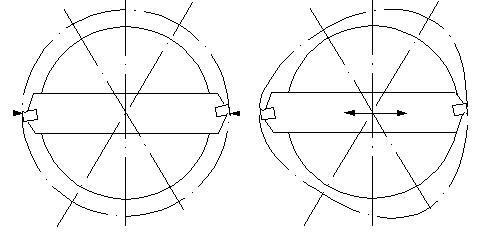

[0048] Refer to the attached figure 1 , figure 2 , image 3 , you can understand the processing technology used in this patent.

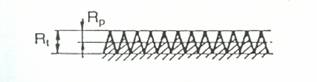

[0049] Refer to the attached Figure 4 , Figure 5It is possible to see the difference in accuracy using the two quantities of skiving tools.

[0050] Refer to the attached Figure 6 The schematic diagram of the main sectional structure of the deep hole processing device shown includes a compound cutter, a boring bar 28 connected with the compound cutter, a boring bar box for driving the boring bar, and a control device for driving the compound cutter to advance and retreat;

[0051] The composite cutter is formed with a center hole, and the composite cutter includes:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com