Automatic depalletizing and stacking machine for line stack-type containers

A depalletizer and stacking type technology, applied in the field of logistics operation equipment, can solve the problems of large operating radius of the mechanical arm, high use and maintenance costs, high labor intensity of workers, etc., and achieve a compact structure, high operation efficiency and high cost performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

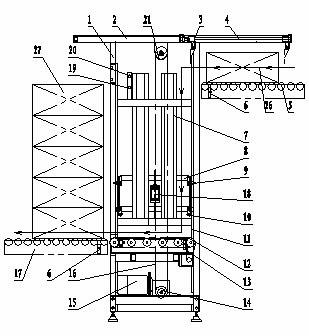

[0018] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

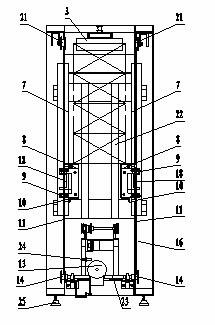

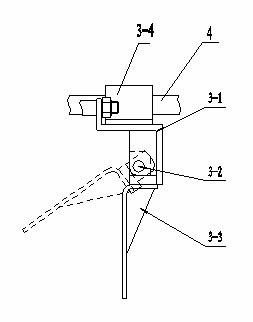

[0019] by attaching figure 1 It can be seen that this scheme provides an in-line stacking type container automatic depalletizer, including a frame 1, a high conveyor 5, a low conveyor 17, a case stack conveyor 12, and sensors on the frame 1 Set up the lifting device. Push box mechanism 3 is also set on frame 1

[0020] by attaching figure 1 attached figure 2 It can also be seen that the lifting device includes a lifting frame 8, a lifting drive mechanism and a lifting channel.

[0021] by attaching figure 1 attached figure 2 It can be seen that the lifting frame 8 is a vertically placed rectangular steel frame, and an opening is left in the direction of the low conveyor 5, and the side guide wheel groups 9 and the front and rear guide wheel groups 10 are respectively installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com