Method for regulating distribution of metal nano granules in resin carrier

A metal nanoparticle, resin carrier technology, applied in chemical instruments and methods, metal material coating process, ion exchange of chelate compounds, etc., can solve problems such as the influence of the performance of the method for regulating the distribution of inorganic metal particles is not explained.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

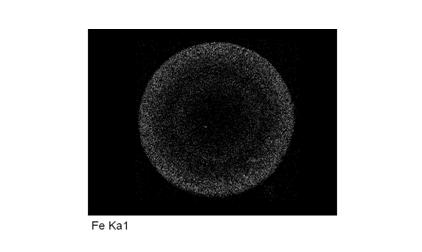

[0031] Add 5g of D-201 resin to 2mol / L of FeCl 4 - In the solution, the solid-to-liquid ratio is 10g / L. Shake to make FeCl 4 - And resin ion exchange reaction 4h, filter. The concentration (weight percentage) is 0.9% NaBH 4 or KBH4 The solution was mixed with it, reacted under ultrasonic vibration for 15 minutes, and then washed with anaerobic water. Vacuum dry at 40°C for 24h. The prepared nano-zero-valent iron is distributed on the periphery of the resin carrier, and its thickness accounts for about 25% of the radius of the carrier section. A scanning electron micrograph of this material is shown in figure 1 shown.

[0032] This composite material reduces 50mg / LNO at the initial pH of the solution=2 3 - The conversion rate of -N is 40%, and the loss rate of Fe is 90%; when pH=6, the product NH 4 + The generation rate is 0.010min -1 .

Embodiment 2

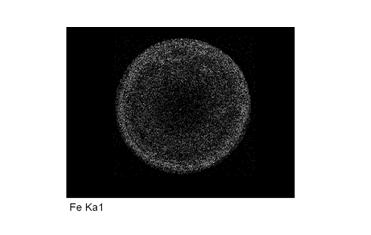

[0034] Add 5g of D-201 resin to 2mol / L of FeCl 4 - In the solution, the solid-to-liquid ratio is 10g / L. Shake to make FeCl 4 - And resin ion exchange reaction 4h, filter. NaBH with a concentration of 1.8% 4 or KBH 4 The solution was mixed with it, reacted under ultrasonic vibration for 15 minutes, and then washed with anaerobic water. Vacuum dry at 40°C for 24h. The prepared nano-zero-valent iron is distributed on the periphery of the resin carrier, and its thickness accounts for about 50% of the radius of the carrier section. A scanning electron micrograph of this material is shown in figure 2 shown.

[0035] This composite material reduces 50mg / LNO at the initial pH of the solution=2 3 - The conversion rate of -N is 44%, and the loss rate of Fe is 76%; when pH=6, the product NH 4 + The generation rate is 0.018min -1 .

Embodiment 3

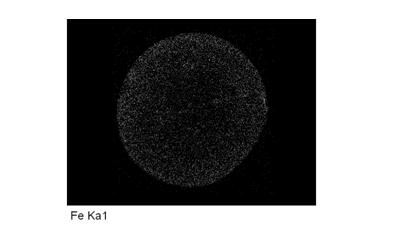

[0037] Add 5g of D-201 resin to 2mol / L of FeCl 4 - In the solution, the solid-to-liquid ratio is 10g / L. Shake to make FeCl 4 - And resin ion exchange reaction 4h, filter. NaBH with a concentration of 3.6% 4 or KBH 4 The solution was mixed with it, reacted under ultrasonic vibration for 15 minutes, and then washed with anaerobic water. Vacuum dry at 40°C for 24h. The prepared nano-zero-valent iron is distributed on the periphery of the resin carrier, and its thickness accounts for about 80% of the radius of the carrier section. A scanning electron micrograph of this material is shown in image 3 shown.

[0038] This composite material reduces 50mg / LNO at the initial pH of the solution=2 3 - The conversion rate of -N is 45%, and the loss rate of Fe is 73%; when pH=6, the product NH 4 + The generation rate is 0.021min -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com