Metal etching liquid composition and etching method

A metal etching and composition technology, applied in the field of metal etching liquid composition, can solve the problems of restricting the use of etching liquid composition, difficult removal of molybdenum residue, unfavorable manufacturing process, etc., so as to reduce the risk of defects, facilitate stability, prolong The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 20

[0042] Embodiment 1 to 20: Preparation and use of etching solution composition

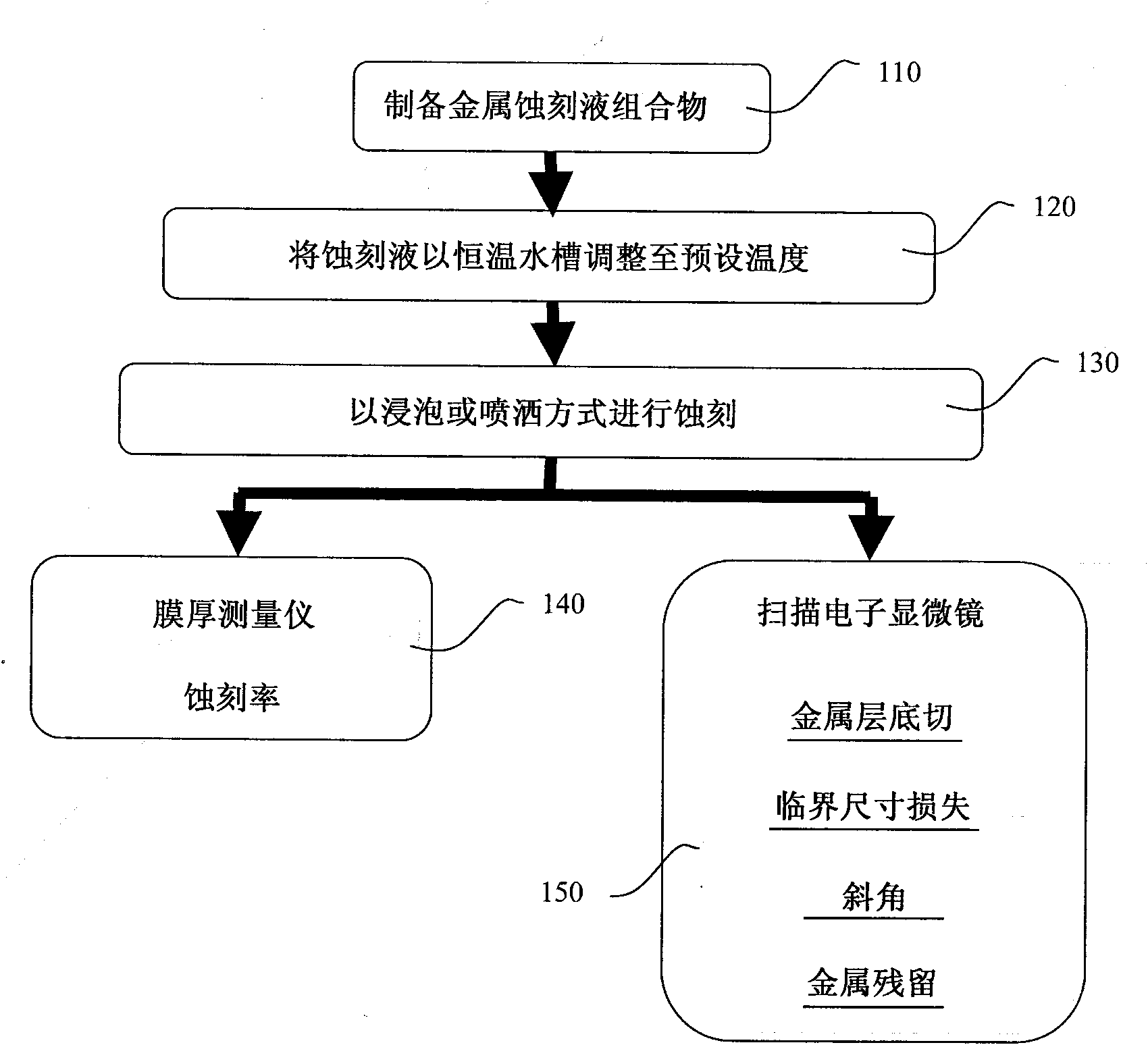

[0043] Such as image 3 As shown in step 110, an etching solution composition containing the ingredients shown in Table 1 and the weight percentage concentrations listed in Table 2 was prepared, wherein the aqueous medium used was deionized water. Subsequently, if image 3 As shown in step 120, the temperature of the etching solution composition is adjusted to a preset 30° C. in a constant temperature water bath.

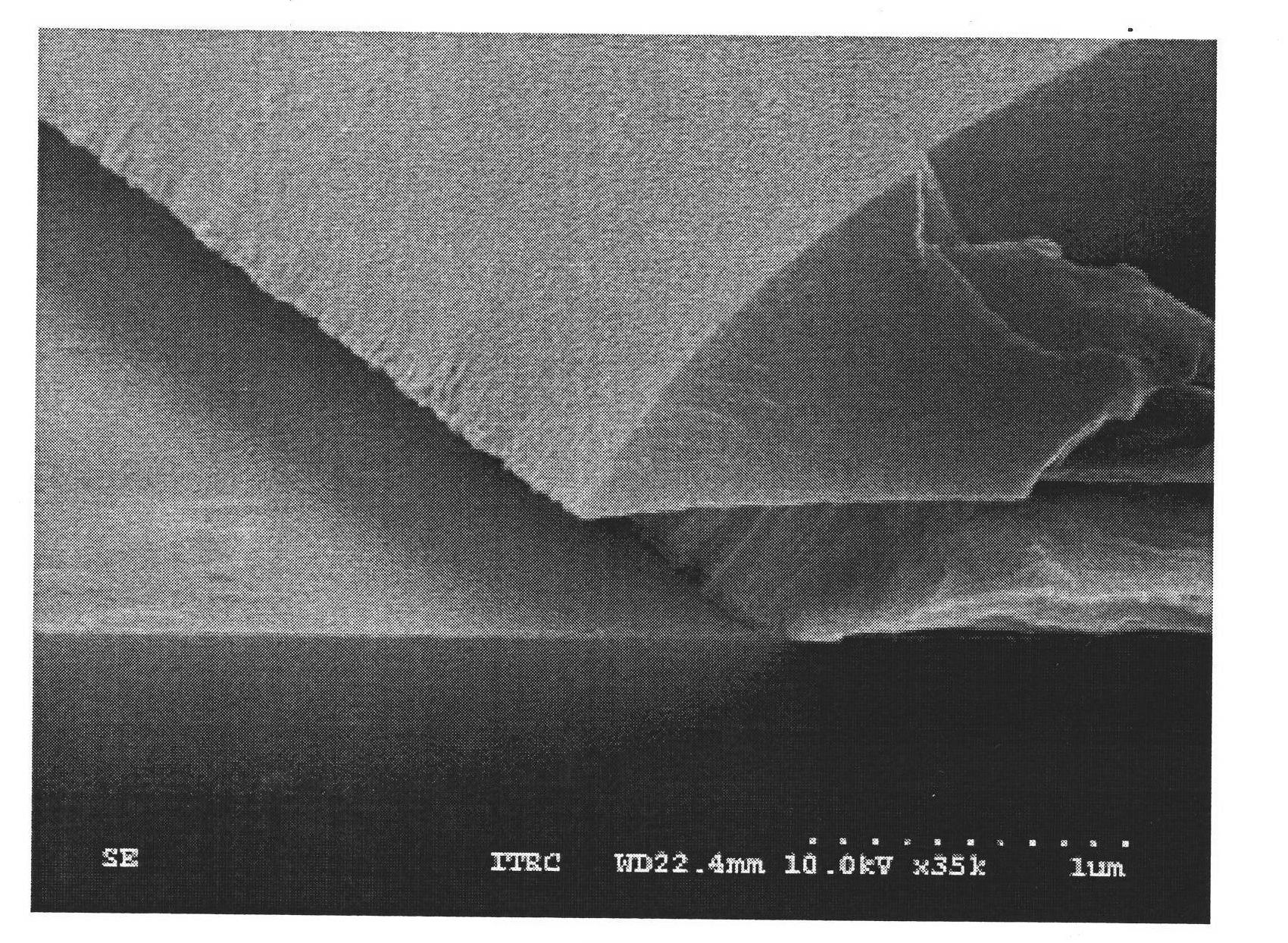

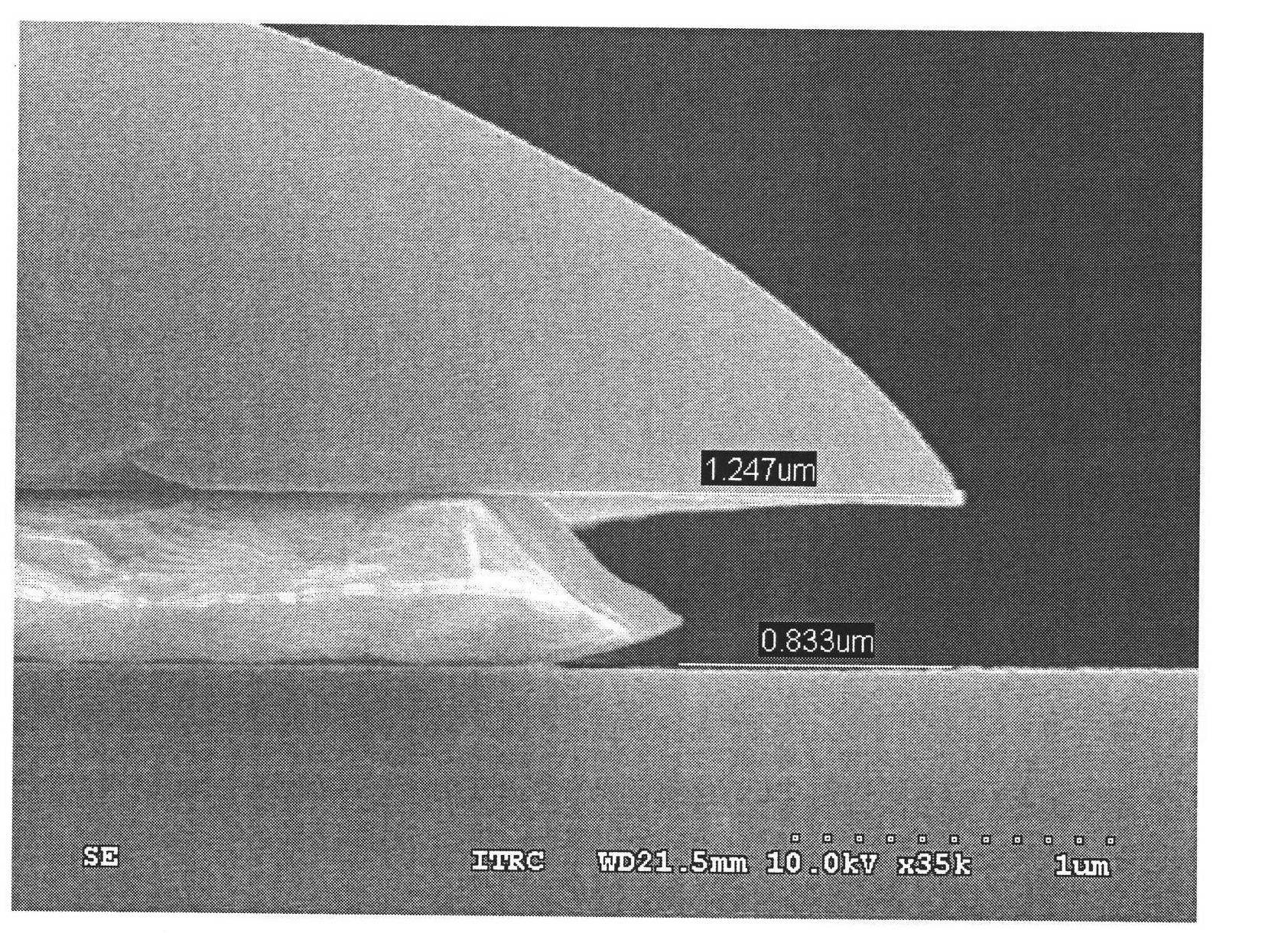

[0044] Then, using the known vapor deposition method in the technical field of the present invention, such as Figure 4 As shown, a multilayer metal 30 containing a molybdenum metal layer 31 and a copper metal layer 32 is sequentially formed on a glass substrate 20, wherein the formed multilayer metal 30 has a thickness of 2150 to And wherein, the thickness of the molybdenum metal layer 31 is 150 to And the thickness of copper metal layer 32 is 2000 to or as Figure 11 As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com