Production method and device of zinc dust

A technology for production equipment and zinc powder, which is applied in the field of zinc powder production equipment and zinc powder production, and can solve problems such as low efficiency in the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

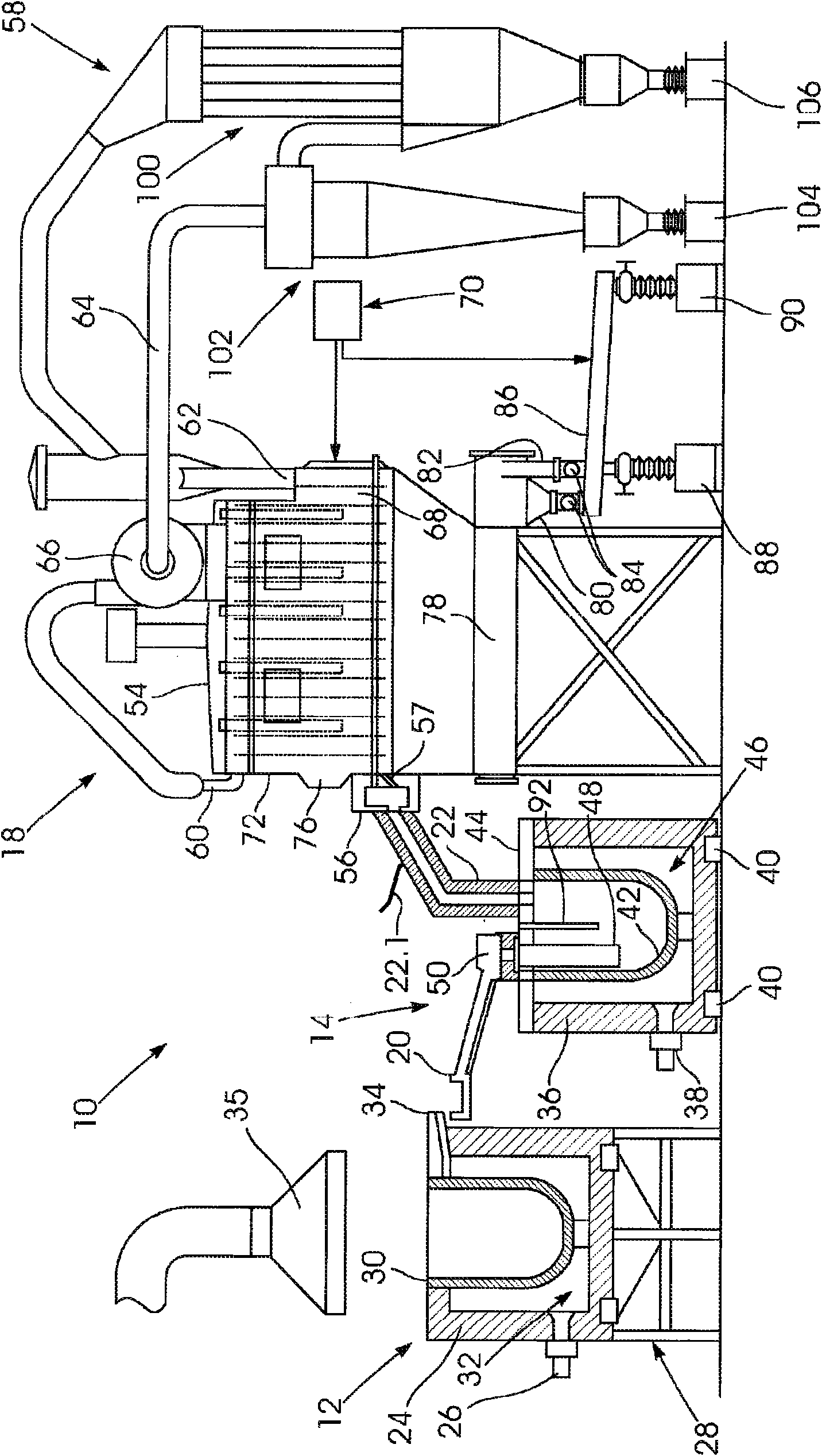

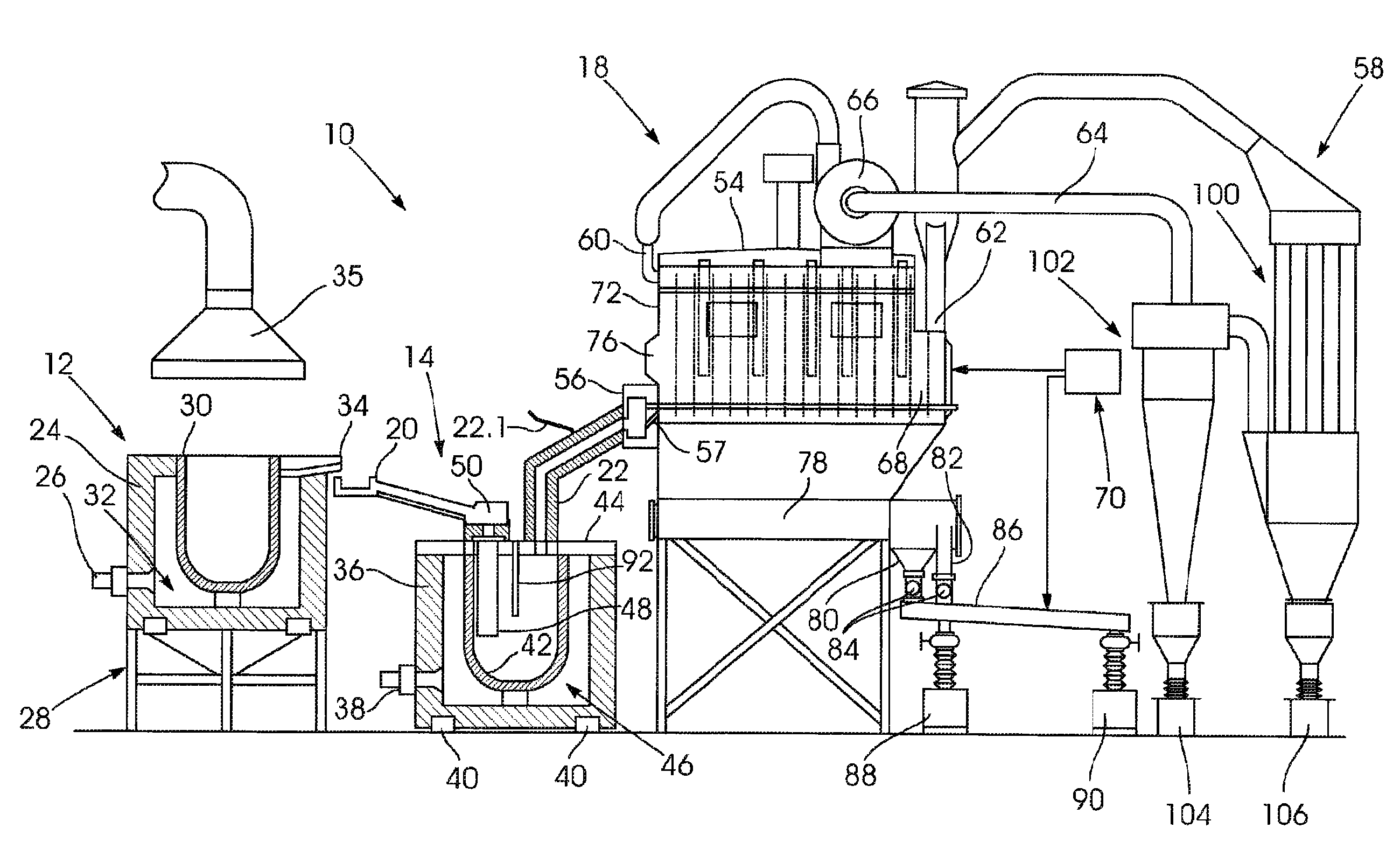

[0054] figure 1 A zinc dust production plant 10 is shown. The apparatus 10 includes a vertical crucible melting furnace 12 , a vertical crucible vaporizer 14 and a condenser 18 . Molten material delivery means in the form of refractory tanks and launders 20 are provided between the melting furnace 12 and the gasification furnace 14 . A vapor delivery means 22 in the form of a silicon carbide jumper is provided between the vaporizer 14 and the condenser 18 .

[0055] The melting furnace 12 includes a refractory lining 24 through which a gas burner 26 protrudes, the burner being located on the inner side of the refractory lining 24 . The refractory lining is mounted on a hydraulically driven inclined table 28 . Inside said furnace lining 24 is provided a silicon carbide melting crucible 30 having an open end exposed to free atmosphere. A burner compartment 32 is defined between the outer wall of the melting crucible 30 and the interior of the refractory lining 24 . An outfl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com