Low-silver lead-free solder alloy

A lead-free solder alloy and solder alloy technology, used in welding/cutting media/materials, welding media, welding equipment, etc., can solve the problems of high alloy cost, copper dissolution to copper content increase, etc., to achieve cost reduction and extended use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

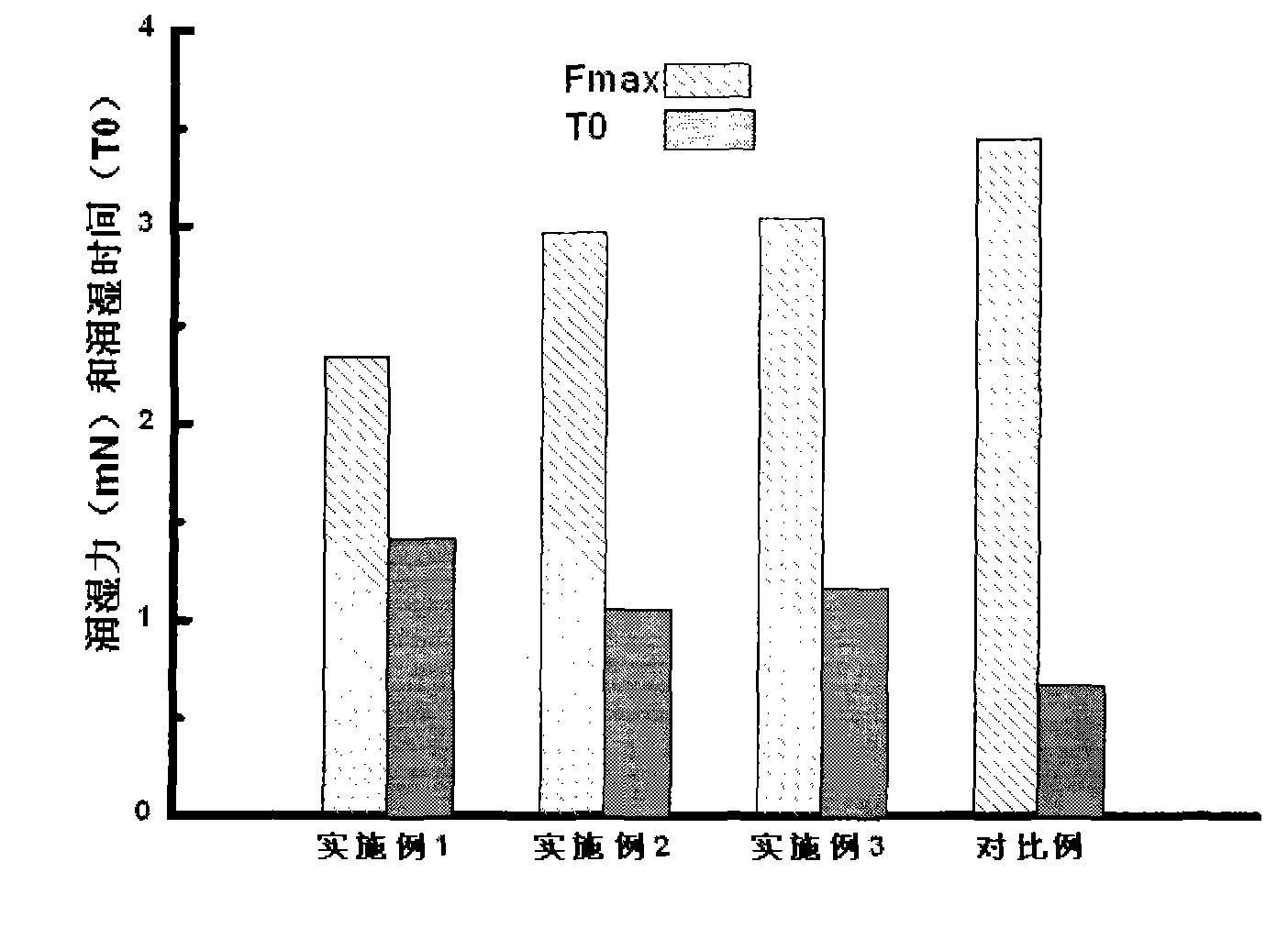

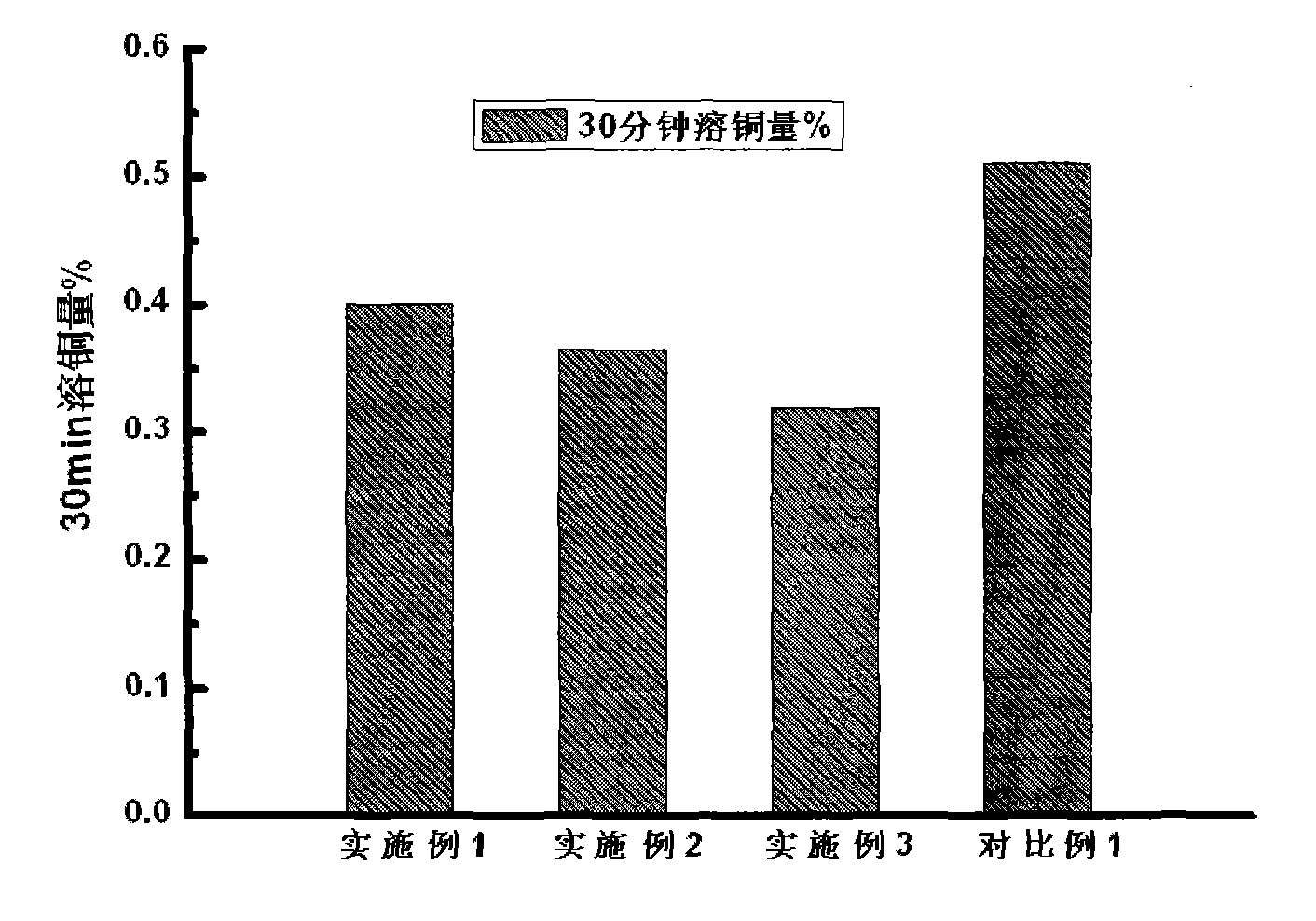

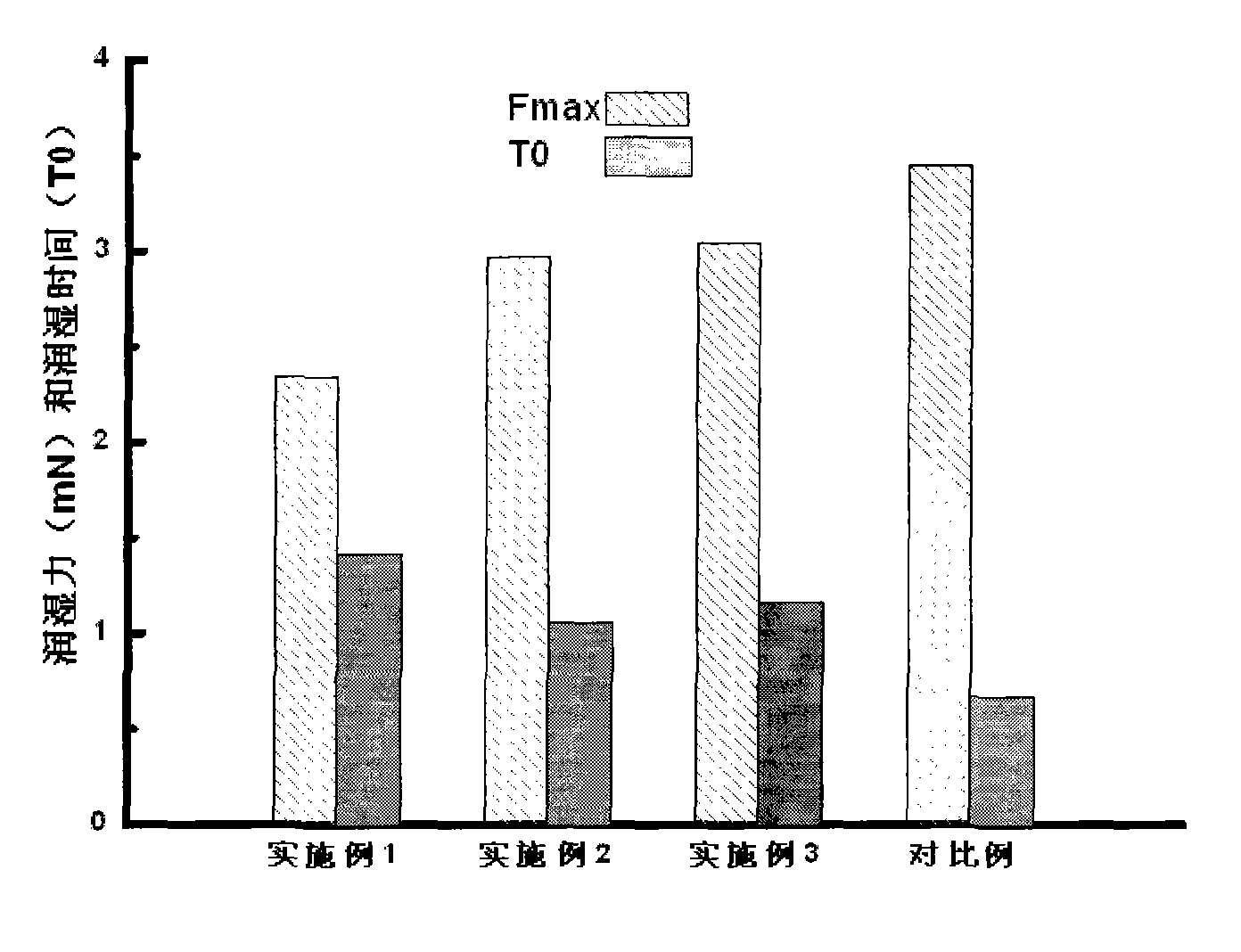

Embodiment 1

[0026] The lead-free solder alloy composition and element weight percentage are as follows: Ag: 0.01wt%, Cu: 3.0wt%, Ni: 0.1wt%, P: 0.1wt%, Ga: 0.02%, Sn is the balance.

Embodiment 2

[0028] The weight percentages of the lead-free solder alloy elements are as follows: Ag: 0.5wt%, Cu: 0.7wt%, Ni: 0.02wt%, P: 0.02wt%, and Sn is the balance.

Embodiment 3

[0030] The composition of lead-free solder alloy elements in weight percent is as follows: Ag: 1.0wt%, Cu: 0.1wt%, Ni: 0.001wt%, P: 0.001wt%, Ga: 0.08%, and Sn is the balance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com