Automatic device for welding and injection molding of radio frequency coaxial jumper assembly

An automatic device, radio frequency coaxial technology, applied in the sequence/logic controller program control, electrical program control and other directions, can solve the problems of large accident, increase in failure rate, difficult high-quality assembly, etc., to achieve fast processing , to ensure the effect of long-lasting, efficient and high-quality assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

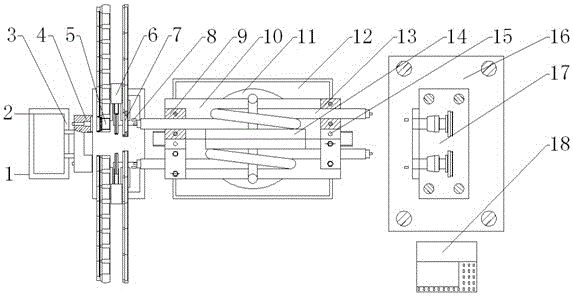

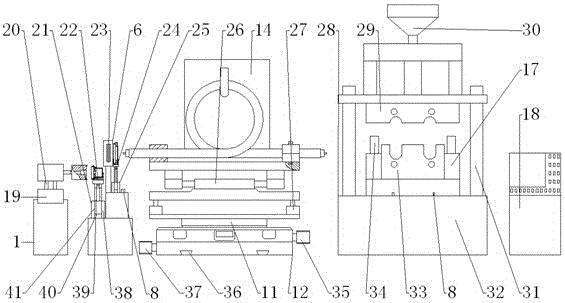

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0035] like figure 1 and figure 2 As shown, a mechanical device for soldering and injection molding of coaxial jumper components, including: feeding device 1, feeder A21, induction heating device 6, feeder B25, laser measuring device 8, workbench 12, Injection molding machine 28, feedback and main control system 18, the above-mentioned devices are arranged in a straight line, and the corresponding working axes are on a horizontal line or in a plane; the feeding device 1 is composed of cylinder A19, piston rod A20, cylinder B2, piston The rod B3 and the vacuum workpiece support 4 are used to clamp the connector liner 5, the cylinder A19 provides vertical movement, and the cylinder B2 provides horizontal movement; the feeder A21 is a straight feeder , is made up of parallel chute A22, electromagnet 38, vibration transmission rod 39, stopper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com