Method for producing toothbrush handle by injection molding for twice

A technology of injection molding and secondary injection molding, which is applied in the direction of coating, etc., and can solve the problems of unclean product surface, deformation, thick brush handle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

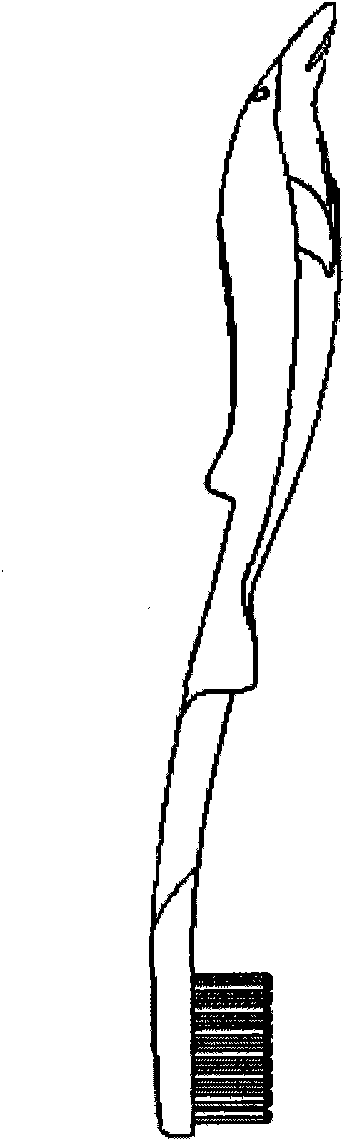

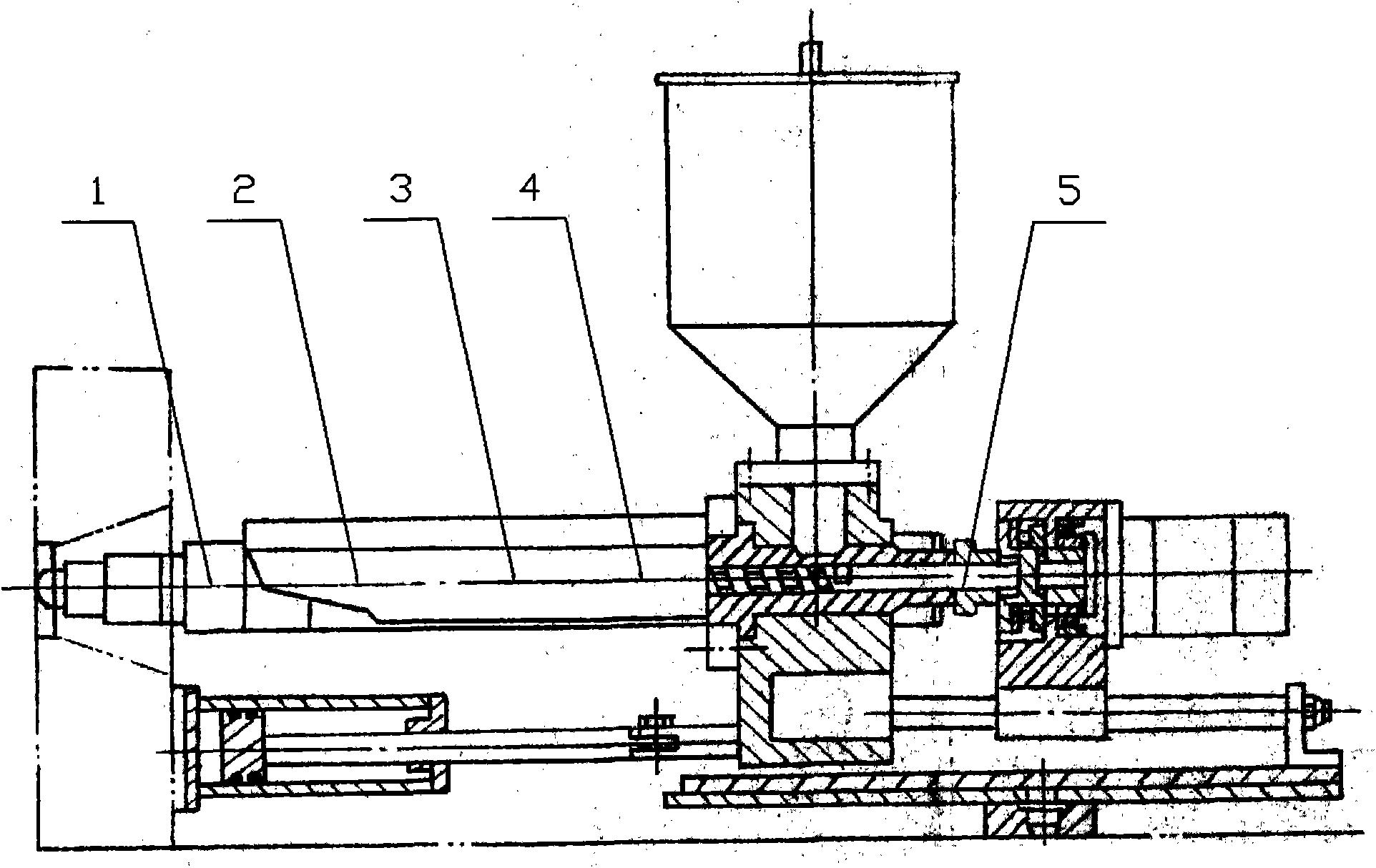

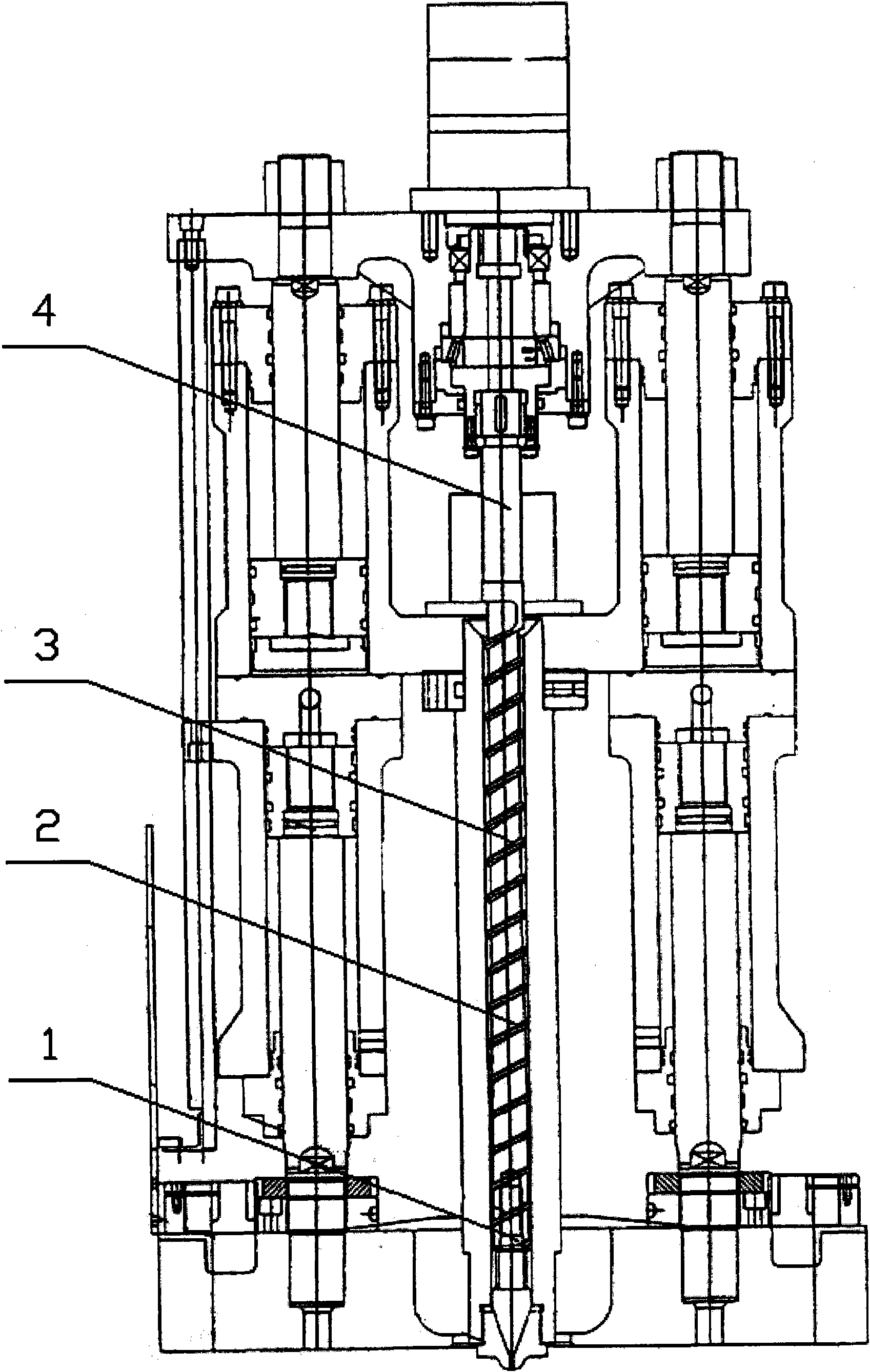

[0038] combined with figure 1 The dolphin-shaped brush handle shown in detail describes the method for producing the brush handle of the present invention, but it needs to be specially explained that the method for producing the brush handle of the present invention is not only used to produce the dolphin-shaped brush handle, but of course the mold can also be adjusted accordingly shapes to manufacture brush handles of other shapes, and various coloring materials can also be added as required to produce brush handles with richer shapes and colors, which can be easily obtained by those skilled in the art on the basis of the present invention. The example of the dolphin-shaped brush handle is only to illustrate the technical solution of the present invention in more detail, but it is not limited thereto. The steps of the injection molding process are described in detail below. The injection molding process of this product is divided into primary injection molding and secondary in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com