Vehicle cutting energy absorption device for rail locomotive

An energy-absorbing device, a technology for rail locomotives, which are applied in railway vehicle wheel guards/buffers, transportation and packaging, railway car body components, etc., can solve problems such as easy failure, large volume, limited energy absorption and energy absorption travel , to achieve the effect of good energy absorption, small volume and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

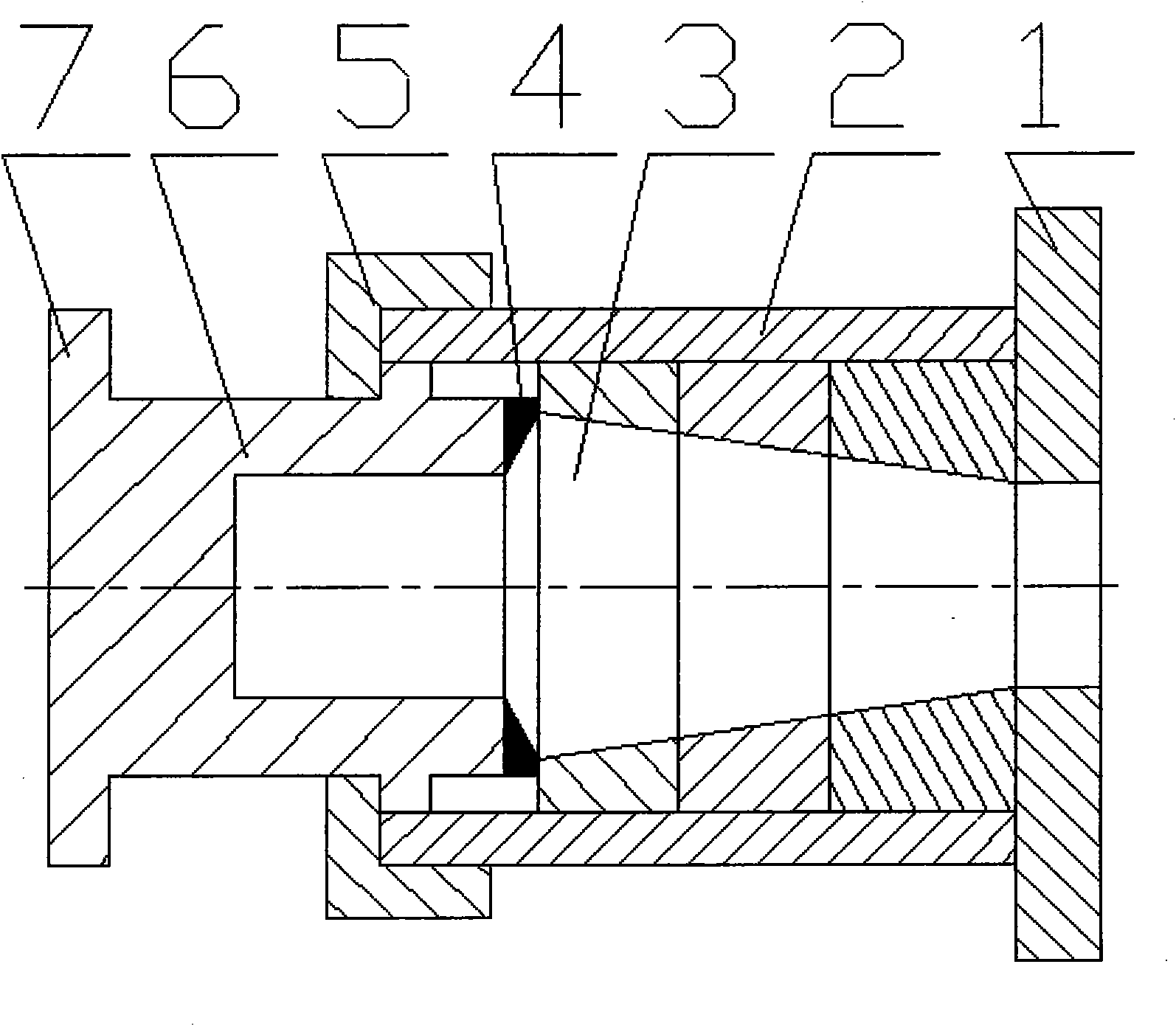

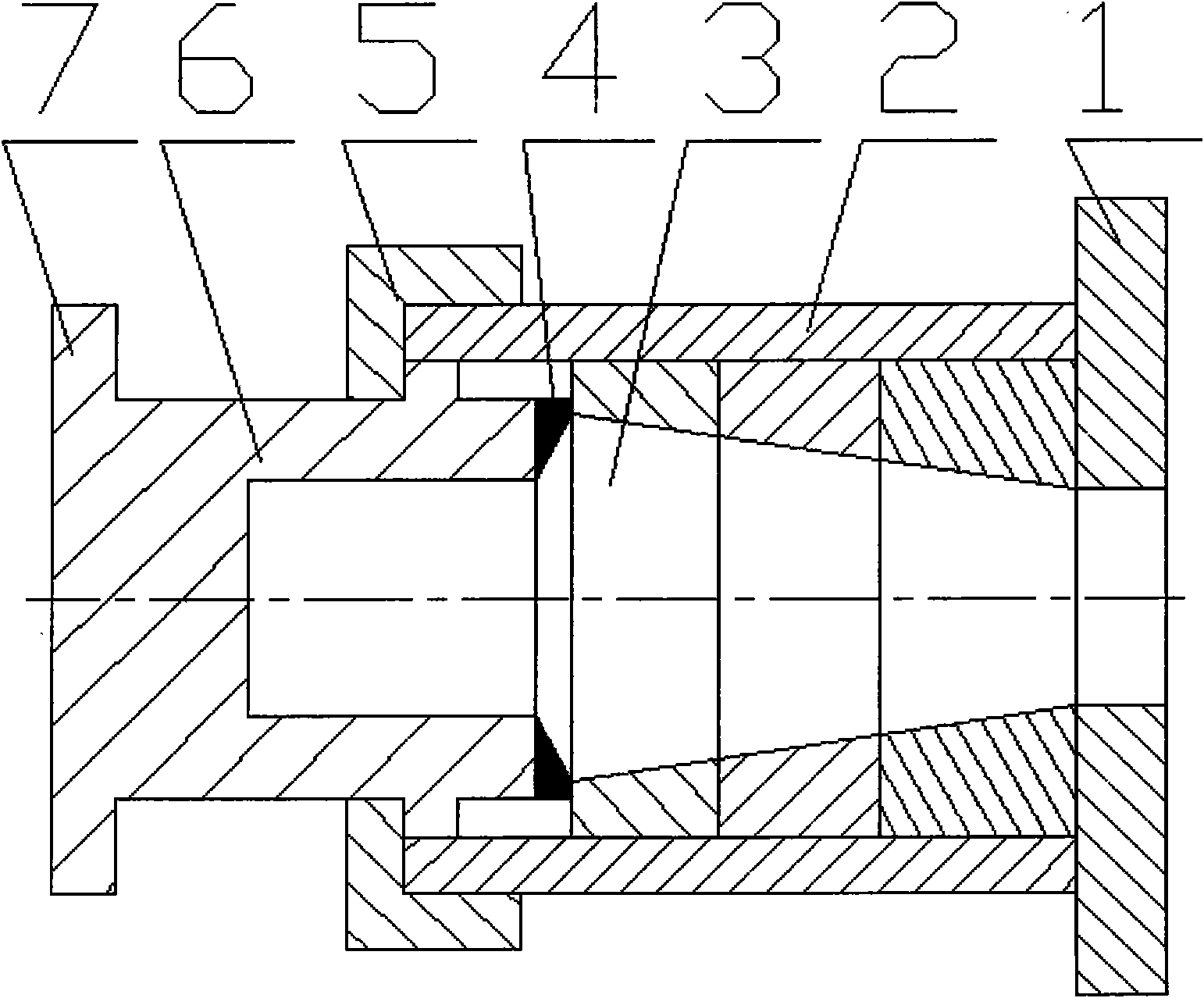

[0025] Referring to the accompanying drawings: the shell 2 is a hollow cylindrical structure, and its two ends are respectively connected to the base 1 and the end cover 5, the base 1 is connected to the locomotive vehicle, and the workpiece 3 is installed in it; normally, the blade of the tool 4 is connected to the workpiece to be cut. 3 contacts, the tool 4 is provided with a tool bar 6, and the end of the bar body of the tool bar 6 exposed to the shell 2 is installed with an impact plate 7; when the tool bar 6 encounters an external impact source, the blade of the tool 4 is inserted into the workpiece 3 to perform cutting and work absorption can. In this embodiment, the blades of the cutter 4 are divided into two groups, the blades of the same group are arranged on the same plane and the same circumference, and the blades of the other group are arranged on another same plane and the same circumference. The cut piece 3 has a variable cross-section and is made of three materi...

Embodiment 2

[0027] It is basically the same as the embodiment, except that the blade of the cutter 4 is in a spiral shape. Under the force of the impact source, the cutter 4 advances in a spiral manner, which obviously increases the path length of the cutter and reduces the volume of the device.

[0028] Embodiments of other combinations will not be described in detail.

[0029] When the cutting edge of the tool 4 is inserted into the workpiece 3 to cut off a set cutting layer, two processes of energy conversion and deceleration and buffering are included.

[0030] The process of energy conversion is to convert the energy of the impact source into heat energy, internal energy of cutting work or other energy through cutting work, so as to achieve the purpose of consuming the energy of the impact source.

[0031] The process of deceleration and buffering, that is, by setting the parameters of the tool 4 and the workpiece 3, the travel speed of the tool 4 is set to change from fast to slow,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com