Electro-hydraulic position servo system capable of quickly inhibiting impact loads and control method of electro-hydraulic position servo system

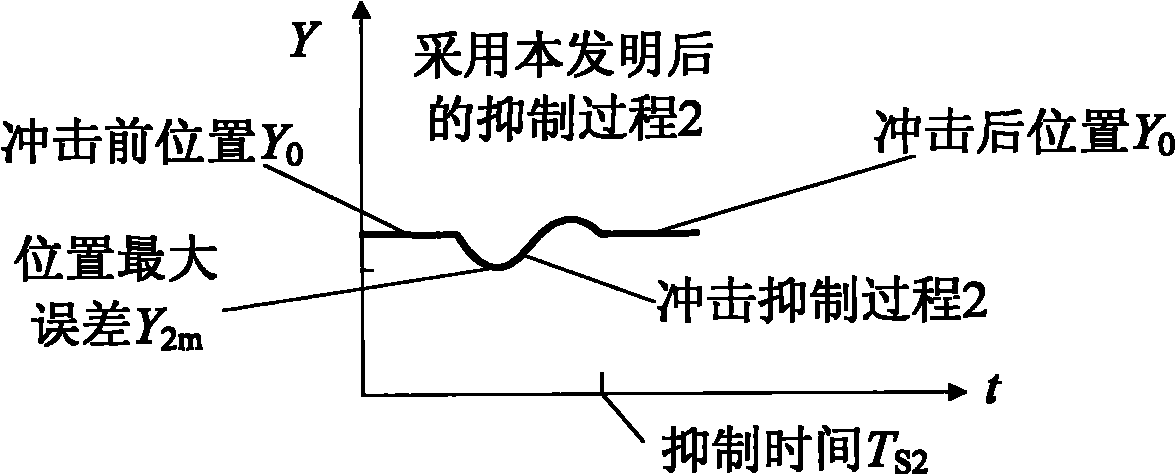

An electro-hydraulic position servo and impact load technology, which is applied to fluid pressure actuation system components, fluid pressure actuation devices, mechanical equipment, etc., can solve problems such as complex system structure and poor interference, and achieve reduced complexity and dynamic fluctuations. The effect of small amplitude and static difference elimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Such as Figure 5 As shown, the electro-hydraulic position servo system with fast suppression of impact load in this embodiment includes a hydraulic source 1, two adder-subtractors 2, 14, a controller 3, an electro-hydraulic servo valve 4, a hydraulic cylinder 5, a load 6. Displacement sensor 7, analog-to-digital converter 12, digital-to-analog converter 15 and power amplifier 16, wherein: it also includes a first pressure sensor 8, a second pressure sensor 9, an anti-shock compensator 10 and a second analog-to-digital conversion device 13, the first pressure sensor 8 is arranged in the oil circuit of the high-pressure chamber of the hydraulic cylinder 5, and the second pressure sensor 9 is arranged in the oil circuit of the low-pressure chamber of the hydraulic cylinder 5, and the signals of the first pressure sensor 8 and the second pressure sensor 9 The output end is connected with the signal input end of the second analog-to-digital converter 13, and the signal outp...

Embodiment 2

[0054] Such as Figure 6 As shown, the electro-hydraulic position servo system with fast suppression of impact load in another embodiment of the present invention includes a hydraulic source 1, two adder-subtractors 2, 14, a controller 3, an electro-hydraulic servo valve 4, and a hydraulic cylinder 5. Load 6, displacement sensor 7, analog-to-digital converter 12, digital-to-analog converter 15 and power amplifier 16, wherein: it also includes a first pressure sensor 8, a gravity balance device 17, an anti-shock compensator 10 and a second mold digital converter 13, the first pressure sensor 8 is arranged in the oil circuit of the high-pressure chamber of the hydraulic cylinder 5, the gravity balance device 17 is arranged in the oil circuit of the low-pressure chamber of the hydraulic cylinder 5, the signal output terminal of the first pressure sensor 8 is connected with the second The signal input end of the analog-to-digital converter 13 is connected, the signal output end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com