Double-raised-head slope-shaped loosening-proof clamp spring with rivet function screw component and using method thereof

A protruding head and backstop technology, used in threaded fasteners, screws, nuts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

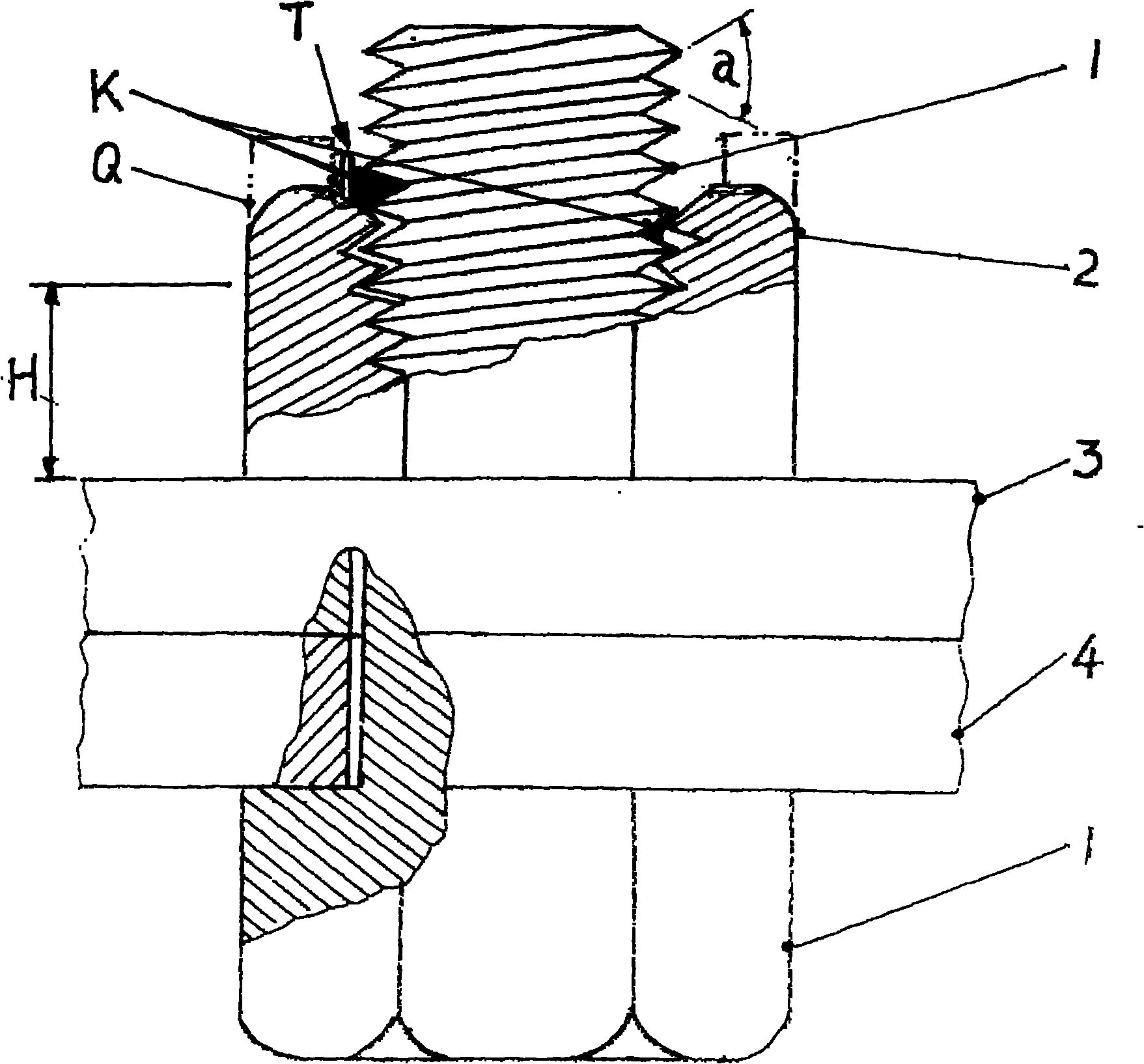

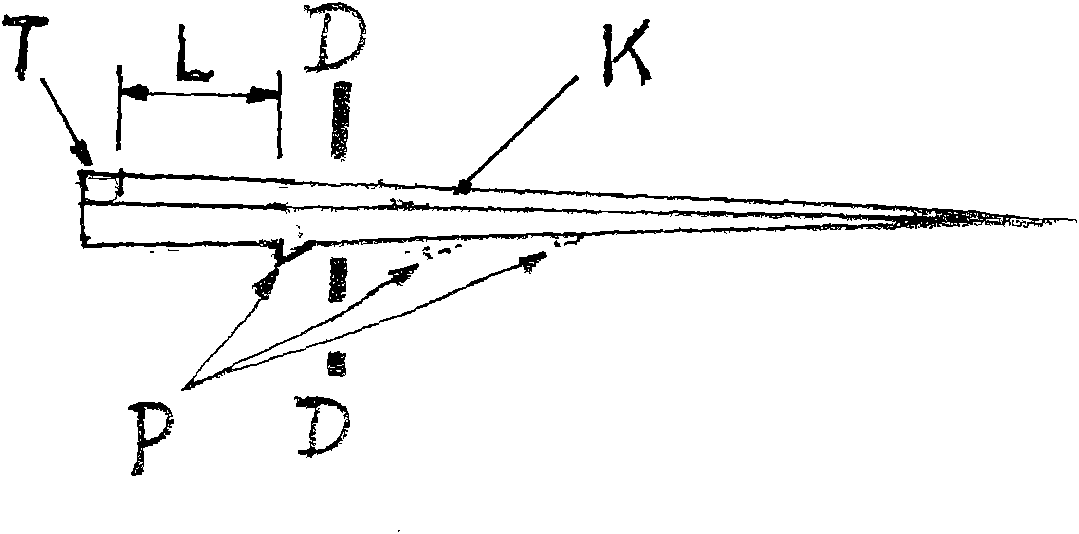

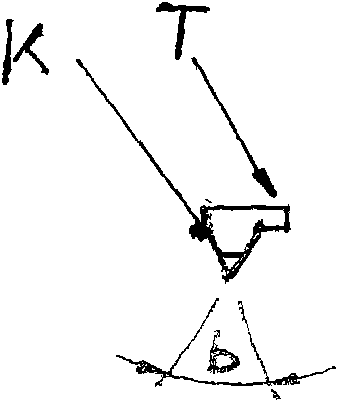

[0009] There is: a single-convex slope-shaped anti-retreat circlip K with at least one non-slip sharp angle P at the lower part of the tail end, which is characterized in that:

[0010] Lengthen the above-mentioned single-protrusion slope-shaped anti-retreat circlip K from its rear portion, and leave the distance L at the rear of the rearmost anti-skid angle P (the L is 2 to 5 times the pitch of the bolt 1 or more) At least one second protrusion T (specially used to reversely pull the slope-shaped back-stop snap ring K—exit original position), making it a double convex slope-shaped back-stop jumper K. And: A. The hardness of the material of the double-convex anti-retraction spring K is greater than that of the bolt 1; B. The cross-sectional angle b of the lower part of the double-convex anti-retraction spring K is smaller than the cross-section of the two walls of the thread groove of the bolt 1 Angle a.

[0011] The protruding direction of the above-mentioned second protrud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com