Guide shell structure of dehumidifier

A dehumidifier and casing technology, applied in the field of guiding casing structure, can solve the problems of increasing the cost of dehumidifier production materials, low overall strength of the dehumidifier casing, and high overall cost of the dehumidifier, achieving planning, overall structural strength, and The effect of saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in detail below with reference to accompanying drawing and embodiment:

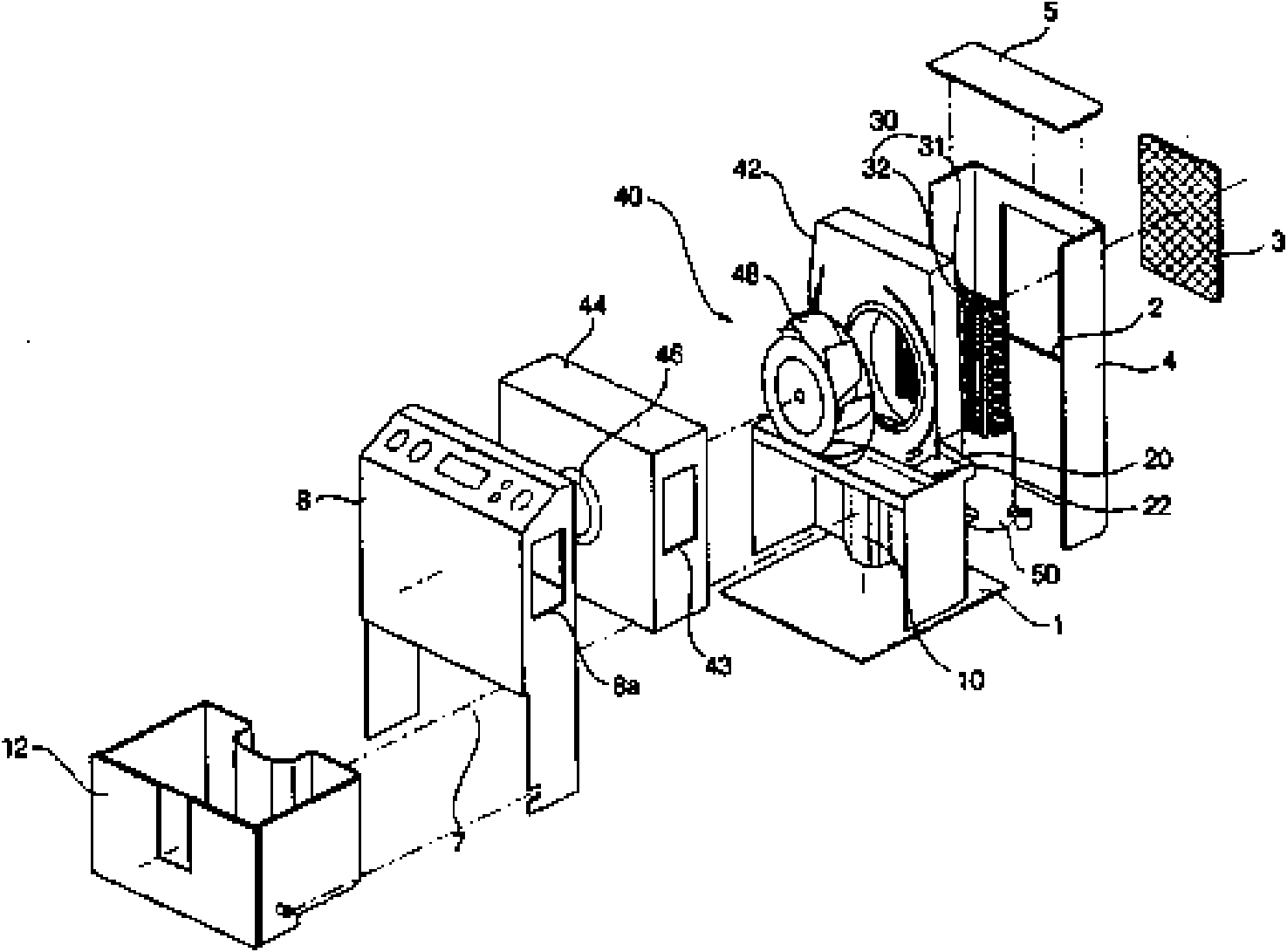

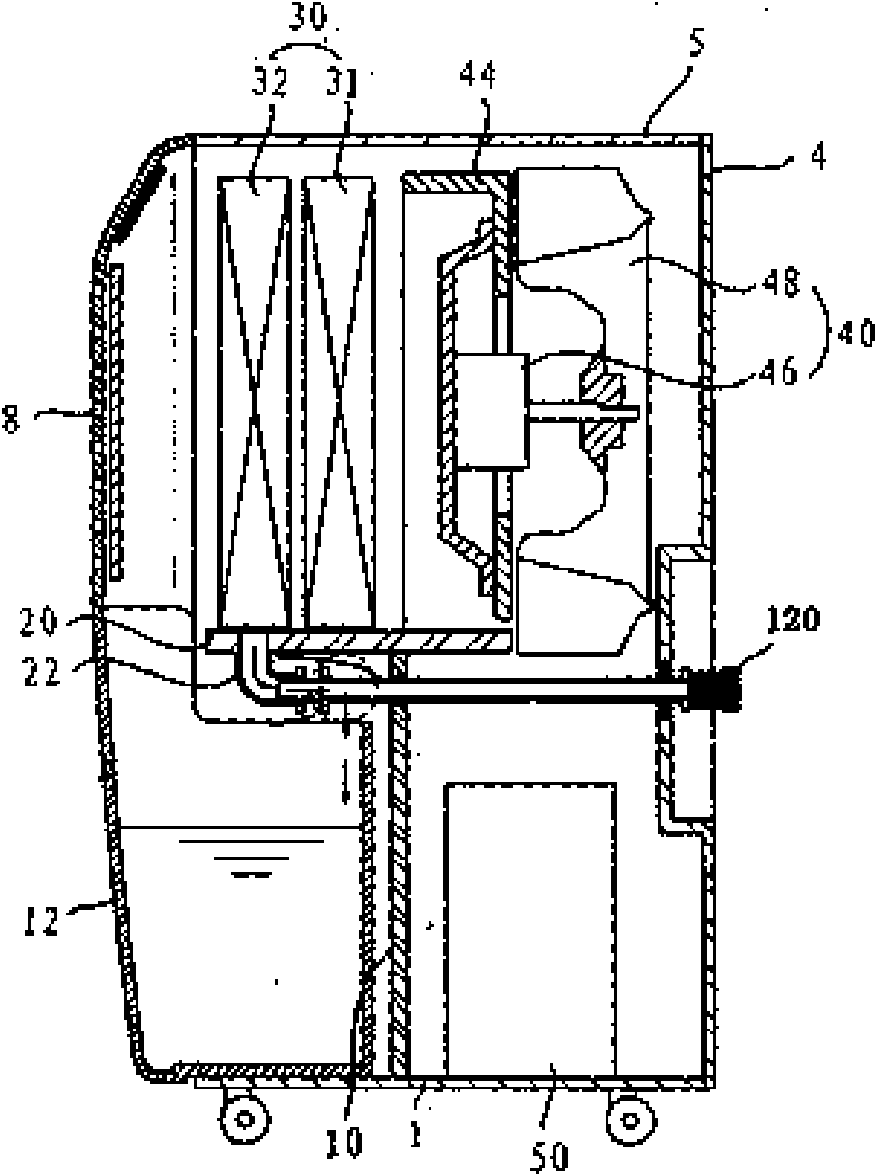

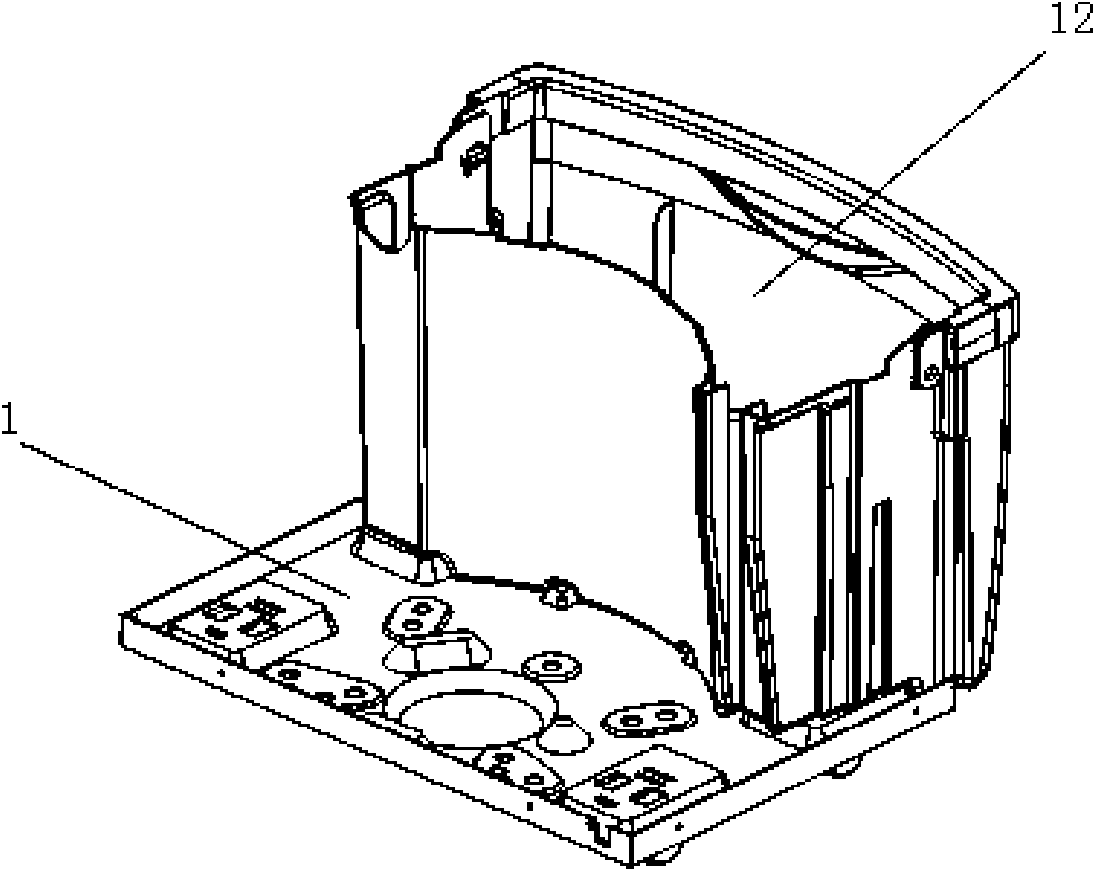

[0029] Figure 4 It is a schematic diagram of the decomposition structure of the dehumidifier of the present invention; Figure 5 It is a schematic diagram of the installation position of the guide shell in the dehumidifier of the present invention; Figure 6 It is a schematic diagram of the guiding shell structure of the dehumidifier of the present invention; Figure 7 It is a plan view of the guide case of the dehumidifier of this invention.

[0030] Such as Figure 4 to Figure 7 As shown, in the guide shell structure of the dehumidifier of the present invention, the cabinet 4 forms the appearance of the dehumidifier, accommodates and protects various components of the dehumidifier; The middle gasification absorbs heat, so the evaporator is in a low temperature state. When the inhaled humid air passes through the evaporator, the moisture in the air condenses...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com