Method for controlling reaction gas channeling of thermobalance analyzer, and pressurized thermobalance analyzer

A technology for analyzers and thermobalances, applied in the field of pressurized thermobalance analyzers, can solve problems such as slow heating rate, inoperability, and unstable measurement of thermal balances, and achieve the effects of fast heating rate, channeling prevention, and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

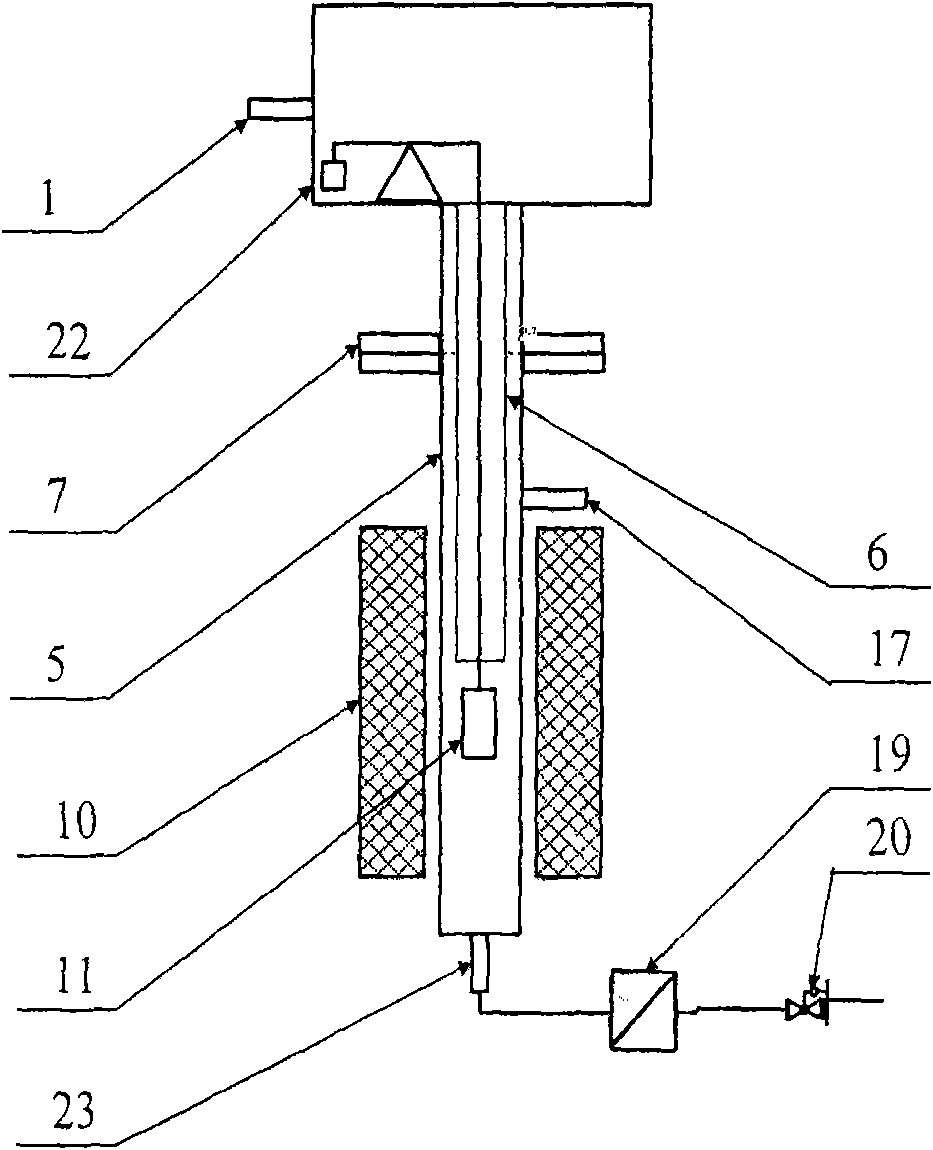

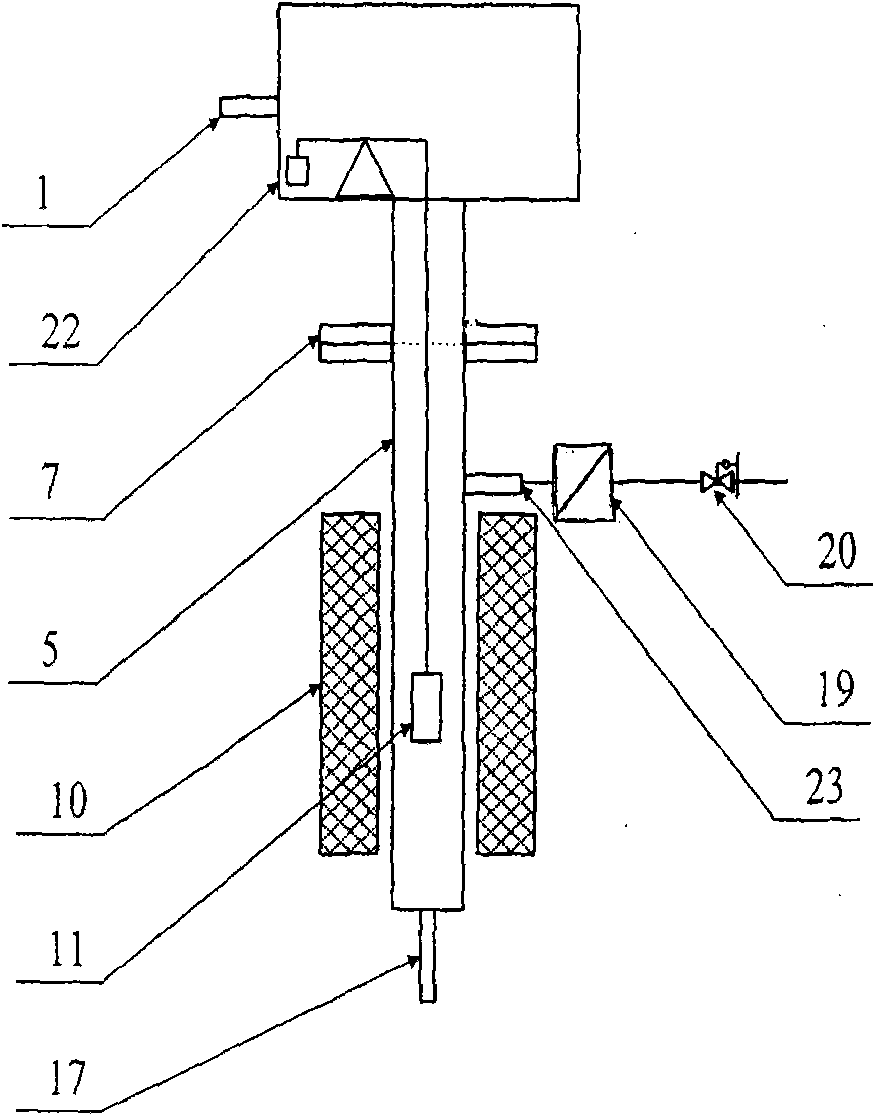

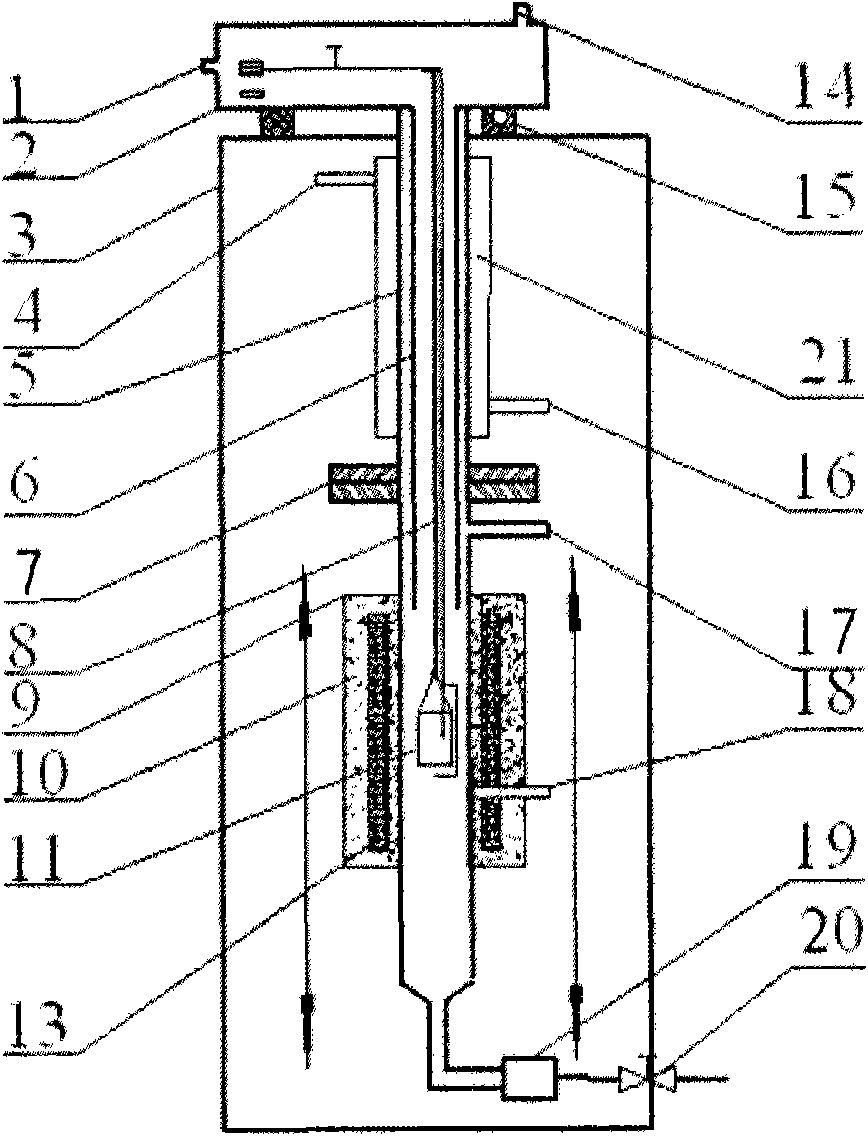

[0054] The pressurized thermobalance analyzer of the present embodiment, its structure comprises:

[0055] The balance in the balance system is a suspended zero balance; one side of the balance cover 2 surrounding the suspended zero balance is provided with a protective gas inlet pipe 1, and the upper end of the balance cover is provided with a data transmission port 14;

[0056] At least one pair of balance supports 15 is installed on the upper surface of a frame-type support 3 whose upper and lower surfaces are horizontal; the balance cover 2 is placed on the upper end of the balance support 15, so that the suspended zero balance is placed in a horizontal state;

[0057] The vertical tubular reactor cavity 5 is composed of upper and lower parts connected by a sealing flange 7;

[0058] The reaction crucible 11 is hoisted in the vertical tubular reactor cavity 5 through the platinum wire connected to the suspended zero balance at the upper end placed vertically; the lower par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com