Method for preparing lens module

A lens module and lens barrel technology, which is applied in the camera body, color TV parts, TV system parts and other directions, can solve problems such as difficulty in assembling parts, lower product yield, etc., and achieve high product yield , The assembly difficulty is low, and the effect of reducing the use of molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

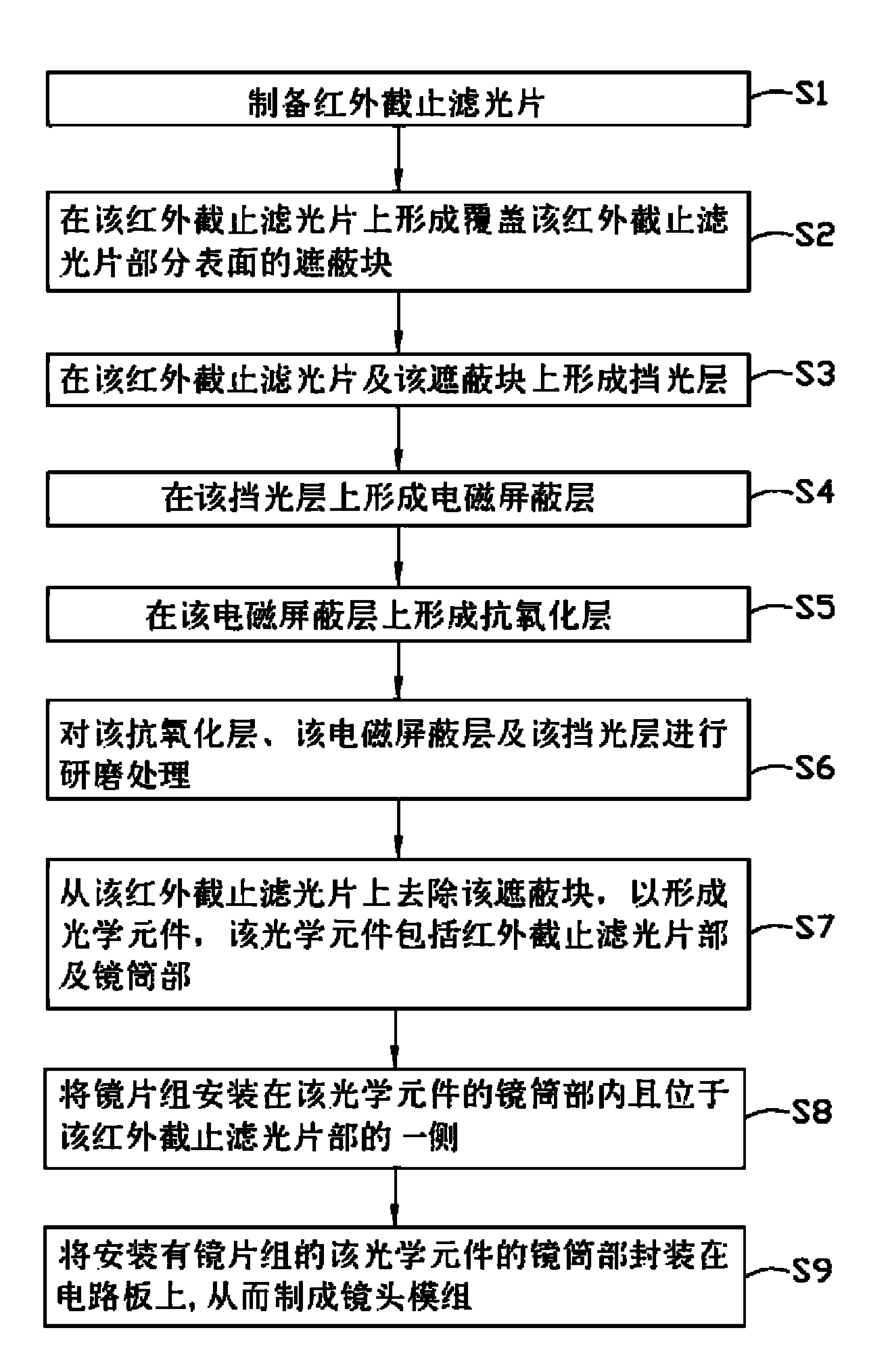

[0019] The preparation method of the lens module of the present invention will be further described in detail in conjunction with the accompanying drawings.

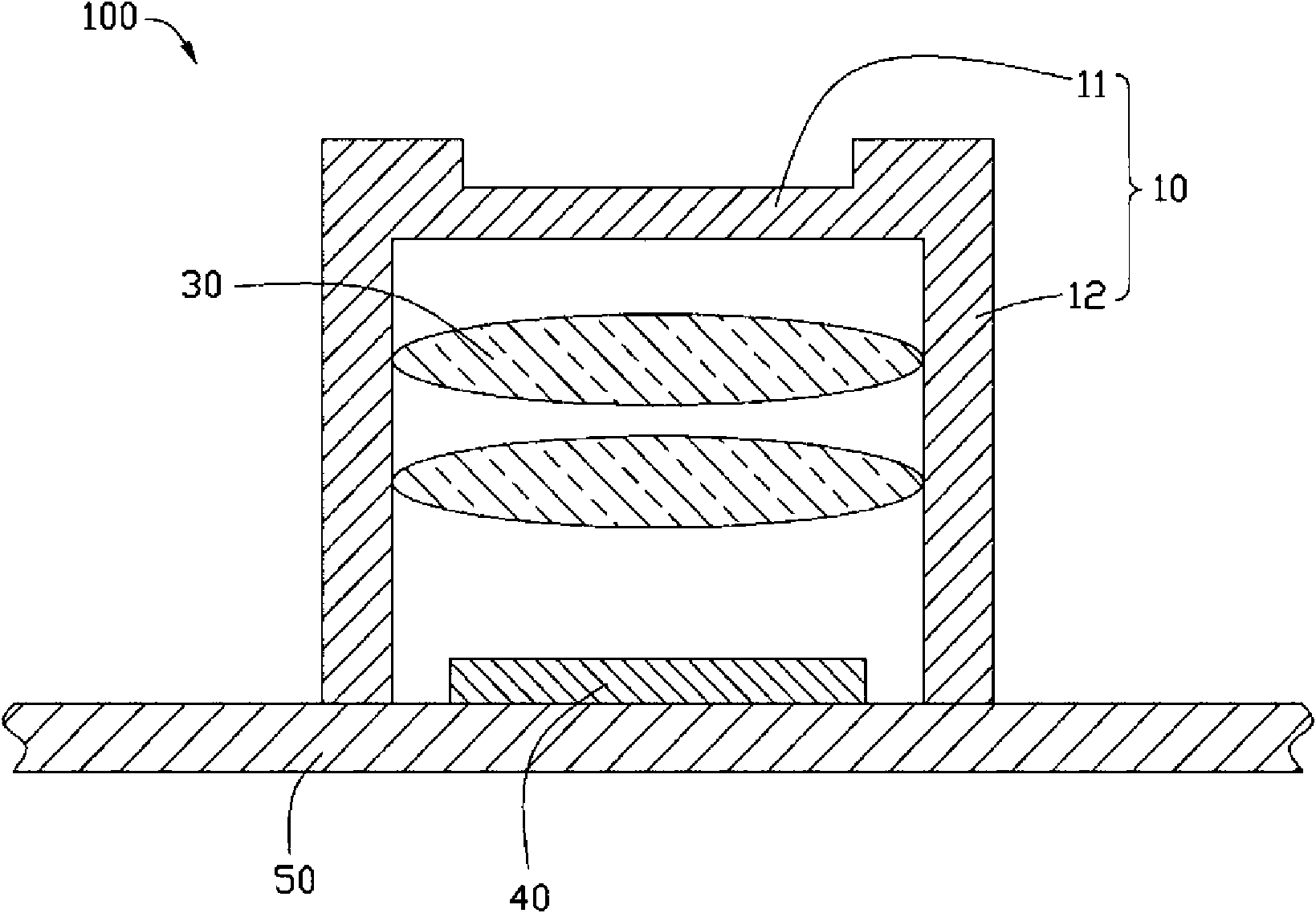

[0020] See figure 1 , a lens module 100 prepared by the method for manufacturing a lens module according to an embodiment of the present invention includes an optical element 10 , a lens group 30 and a circuit board 50 . The optical element 10 includes an infrared cut filter part 11 and a barrel part 20 . The infrared cutoff filter part 11 is located at one end of the lens barrel part 20 and is integrally structured with the lens barrel part 20 . The lens group 30 is disposed in the barrel portion 20 and located on one side of the infrared cut filter portion 11 . One end of the lens barrel part 20 away from the infrared cut filter part 11 is fixed to the circuit board 50 .

[0021] The infrared cut-off filter part 11 is mainly used to filter the light in the infrared band entering the lens module 100 and let the light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com