System and method for processing flue gas

A technology of flue gas and gas flow, applied in chemical instruments and methods, separation methods, gas treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

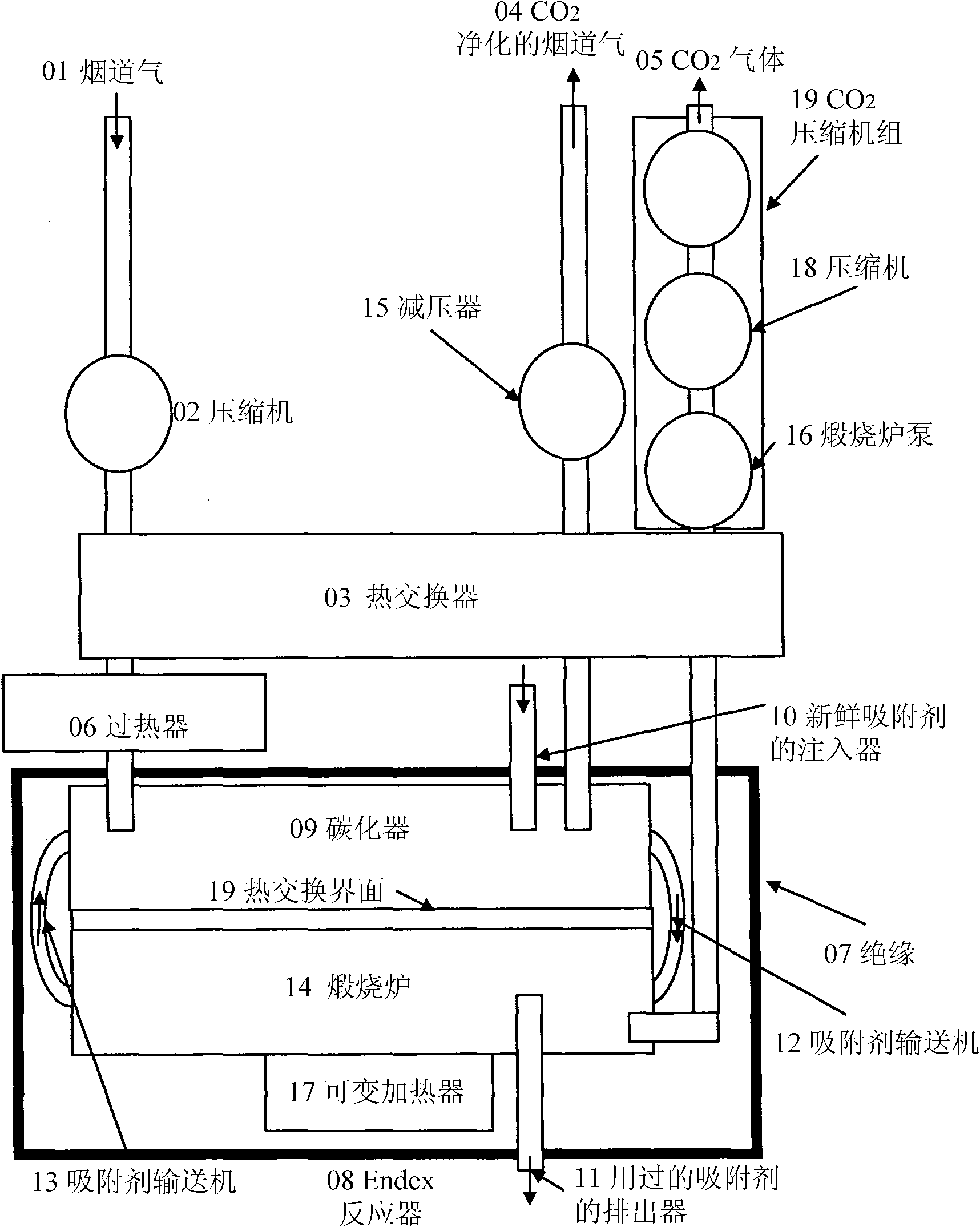

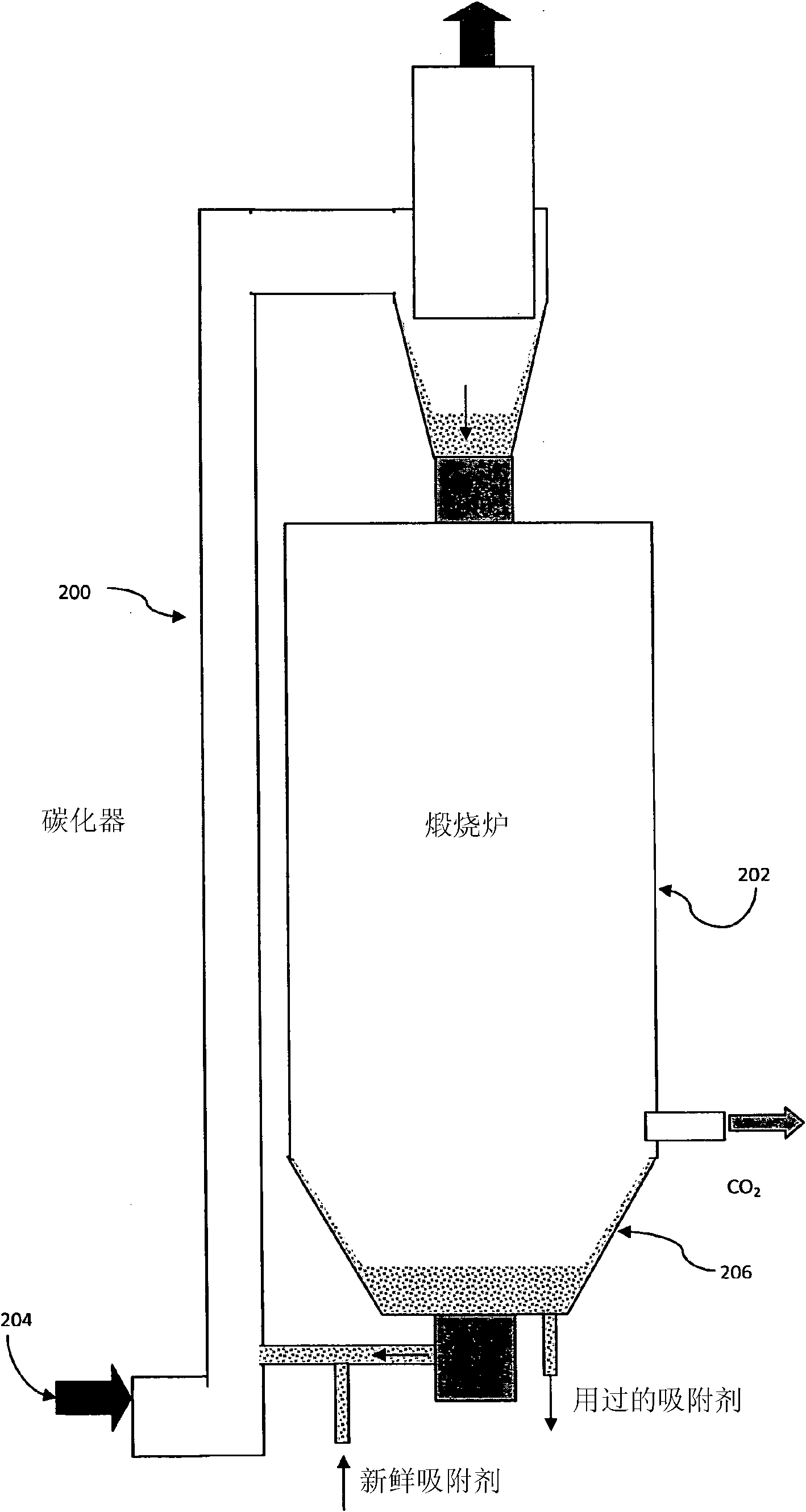

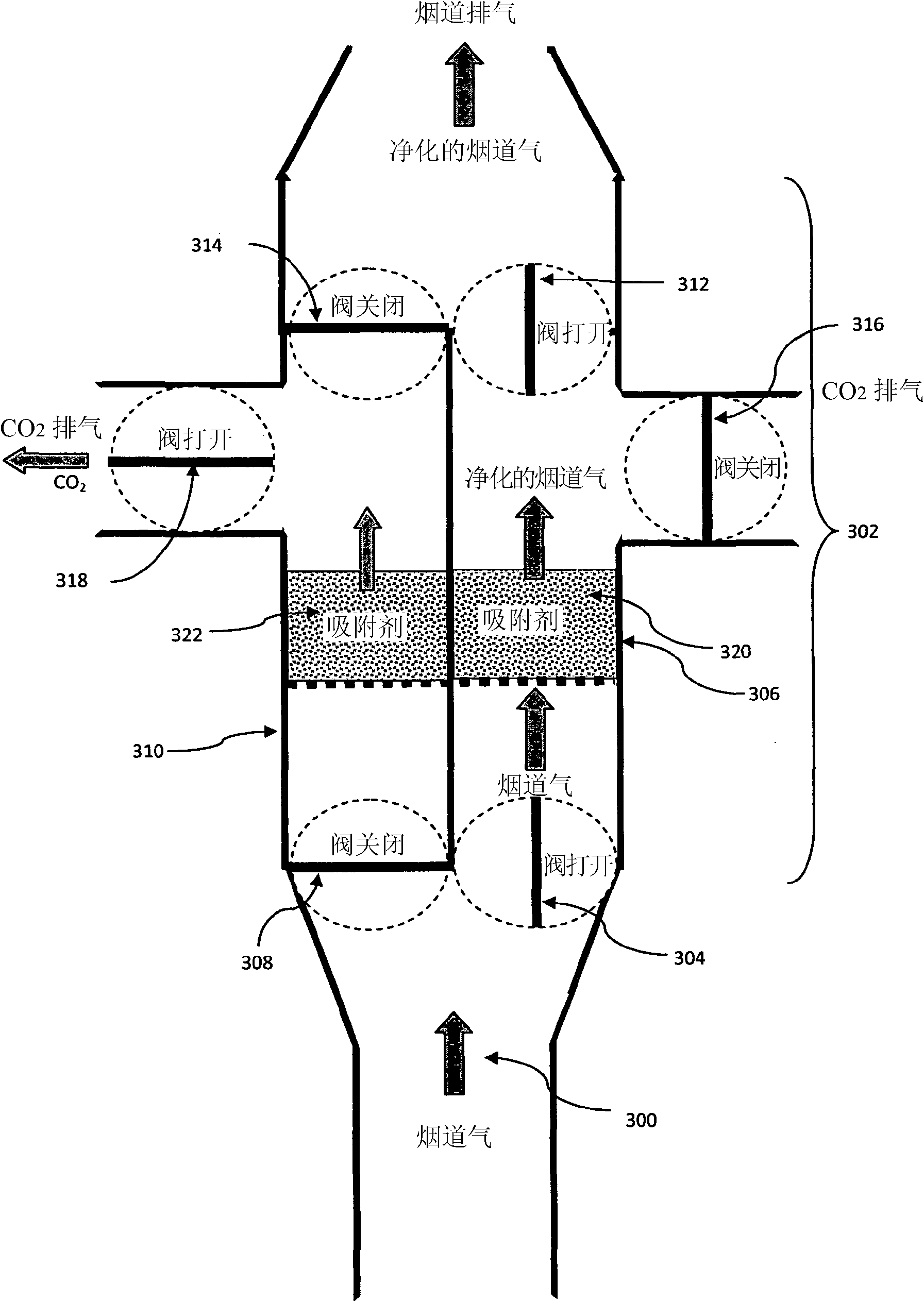

Method used

Image

Examples

Embodiment Construction

[0042] ζ = 1 - p CO 2 , out p CO 2 , in 1 - p eq ( T carb ) p CO 2 , in - - - ( 1 )

[0043] In the above exemplary embodiments, at T calc carb The operation in the scheme is a deliberate deviation (or change) from the existing scheme that sets the temperature of the endothermic reactor (calciner) higher than t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com