Applying device and applying method for transverse rubber band-type elastic waist of paper diaper

An elastic waist circumference and application device technology, applied in medical science, bandages, absorbent pads, etc., can solve the problems of complex elastic waist circumference manufacturing process, poor elastic waist circumference, unstable equipment operation, etc., and achieve low cost and good elasticity. , Online production of high-efficiency effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

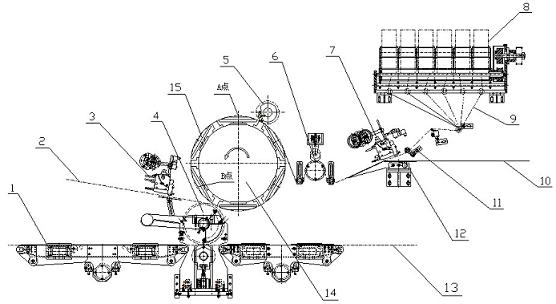

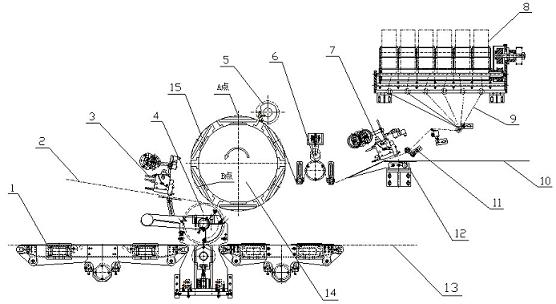

[0010] Embodiment 1: with reference to attached figure 1 with 2 . The device for making and applying the transverse elastic waistline of diapers includes an elastic unwinding mechanism 8, a non-woven fabric wrapping mechanism 12, an elastic glue gun 7, a material traction assembly 6, a cutter assembly 5, a bottom knife and a steering wheel device 14 , elastic waist glue gun 3, negative pressure adsorption wheel device 4 and negative pressure belt conveying assembly 1, each of the above-mentioned parts is existing equipment, and will not be described here; the elastic uncoiling mechanism 8 is the first station, and then It is a rubber band sizing gun 7, a non-woven fabric wrapping mechanism 12, a material traction assembly 6, a bottom knife and a steering wheel device 14, a cutter assembly 5, an elastic waist glue gun 3, a negative pressure adsorption wheel device 4, and a negative pressure belt Conveyor assembly 1; rubber transition guide assembly 11 is provided between the ...

Embodiment 2

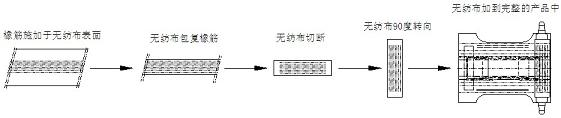

[0011] Example 2: On the basis of Example 1, the method of applying the elastic waist circumference of the diaper transverse elastic type: State 1: The elastic uncoiling mechanism 8 arranges multiple elastic bands 9 at the same time according to a certain degree of tightness and spacing through the elastic guide wheel Cloth to the surface of the non-woven fabric around the waist; State 2: apply a certain amount of hot melt adhesive to the arranged rubber bands as required by the rubber band sizing gun 7 to bond them to the non-woven fabric, and wrap them with the non-woven fabric The mechanism 12 wraps the non-woven fabric into a predetermined width, so that the elastic 9 is completely in the non-woven fabric; State 3: the traction wheel in the material traction assembly 6 pulls the wrapped non-woven fabric to the bottom knife and the steering wheel device 14 On the suction box on the surface of the steering wheel, it moves together with the steering wheel. Since there are six ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com