Sucrose-melamine-formaldehyde (SMF) copolycondensation resin wood adhesive and preparation method thereof

A technology of co-polycondensation resin and wood adhesive, applied in the direction of adhesive, aldehyde/ketone condensation polymer adhesive, adhesive type, etc., can solve the problem of severe reaction of industrial sucrose modified MF, short storage period of resin, difficult to control, etc. problem, to achieve the effect of low cost, long shelf life and similar performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] (1) Get 220 parts by weight of formaldehyde solution with a mass fraction of 37%, adjust the pH to 8.5 with sodium hydroxide solution, add 0.25% borax as a crosslinking agent under stirring, add 126 parts by weight of melamine, 137 parts by weight after reacting for 5 minutes Parts of sucrose, gradually warming up to 88 ~ 96 ℃;

[0012] (2) After insulated reaction at this temperature for 30 minutes, add water to dilute the solid content of the resin to 46-48% when the water dilution of the reaction solution reaches 2 times, adjust the pH to 8.5 with sodium hydroxide solution, and then cool and discharge the material to obtain final product Sucrose-melamine-formaldehyde polycondensation resin wood adhesive.

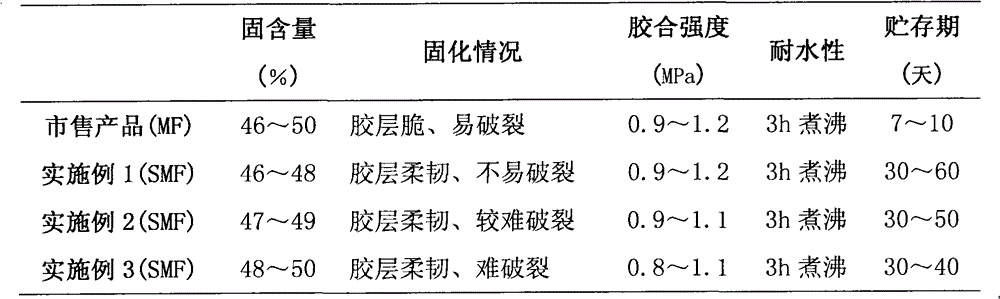

[0013] In the preparation of this example, the molar ratio of sucrose to melamine was 0.4:1; the obtained adhesive was a golden yellow liquid with a solid content of 46-48%, a pH of 8.5, and a storage period of 30-60 days.

Embodiment 2

[0015] (1) Get 220 parts by weight of formaldehyde solution with a mass fraction of 37%, adjust the pH to 8.5 with sodium hydroxide solution, add 0.30% borax as a crosslinking agent under stirring, add 126 parts by weight of melamine, 188 parts by weight of melamine after 10 minutes of reaction Parts of sucrose, gradually warming up to 90-98°C;

[0016] (2) After insulated reaction at this temperature for 30 minutes, add water to dilute the solid content of the resin to 47-49% when the water dilution of the reaction solution reaches 2.5 times, adjust the pH to 8.5 with sodium hydroxide solution and then cool the material to obtain final product Sucrose-melamine-formaldehyde polycondensation resin wood adhesive.

[0017] In the preparation of this example, the molar ratio of sucrose to melamine is 0.55:1; the obtained adhesive is a light yellow liquid with a solid content of 47-49%, a pH of 8.5, and a storage period of 30-50 days.

Embodiment 3

[0019] (1) Get 220 parts by weight of formaldehyde solution with a mass fraction of 37%, adjust the pH to 9.0 with sodium hydroxide solution, add 0.33% borax as a crosslinking agent under stirring, add 126 parts by weight of melamine, 240 parts by weight of melamine after 15 minutes of reaction Parts of sucrose, gradually warming up to 90-98°C;

[0020] (2) After insulated reaction at this temperature for 30 minutes, add water to dilute the solid content of the resin to 48-50% when the water dilution of the reaction solution reaches 3 times, adjust the pH to 9.0 with sodium hydroxide solution, and then cool and discharge the material to obtain final product Sucrose-melamine-formaldehyde polycondensation resin wood adhesive.

[0021] In the preparation of this example, the molar ratio of sucrose to melamine was 0.7:1; the obtained adhesive was a golden yellow liquid with a solid content of 48-50%, a pH of 9.0, and a storage period of 30-40 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com