Low nucleic acid yeast product, preparation method thereof and weight-reducing product comprising same

A low-nucleic acid yeast and nucleic acid content technology, applied in the field of low-nucleic acid yeast products and their preparation, can solve the problems of no edible or health care value of yeast, uncontrolled yeast content, and nutritional loss of yeast, etc., so as to reduce the risk of causing gout, The method is simple and feasible, and the effect of promoting fat decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

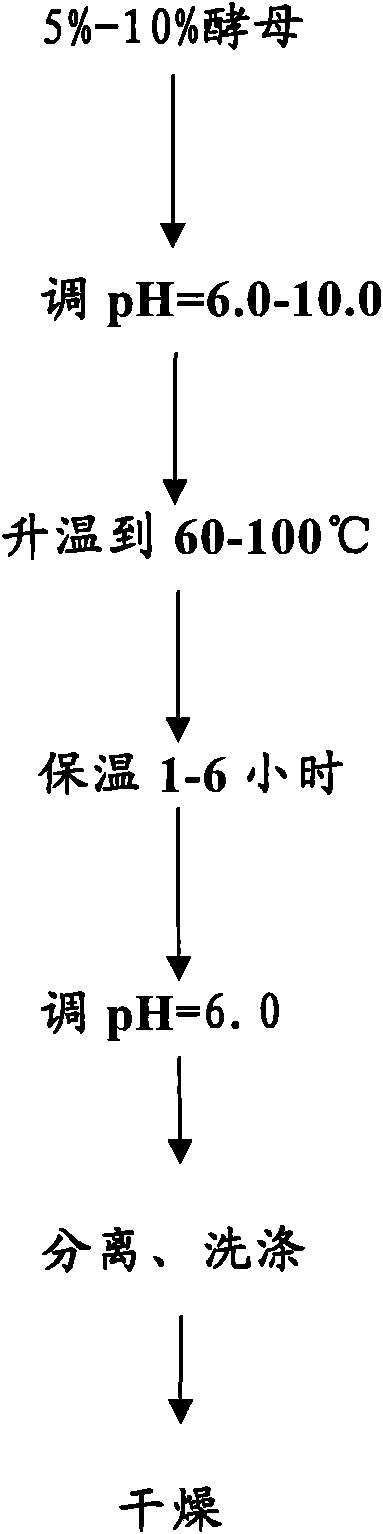

Method used

Image

Examples

Embodiment 1

[0027] Take Angel Saccharomyces cerevisiae produced by Angel Yeast Co., Ltd., add deionized water, and prepare a solution with a mass percent concentration of 5%; adjust the yeast solution to pH=6.0 with sulfuric acid and sodium hydroxide; then, the yeast The solution was incubated at 60°C for 1 hour; then adjust the yeast solution to pH = 5.0; separate with a laminated separator, collect the separated heavy phase, then add water to the obtained heavy phase, the amount of water added is the same as the volume of the obtained heavy phase, and stir After 30 minutes, use a separator to separate, and spray-dry the resulting heavy phase to obtain a low-nucleic acid yeast sample 1 # .

Embodiment 2

[0029] Take the Angel beer yeast produced by Angel Yeast Co., Ltd., add deionized water, and prepare a solution with a mass percentage concentration of 7%; adjust the yeast solution to pH=9 with sulfuric acid and sodium hydroxide; then, the yeast The solution was incubated at 80°C for 4 hours; then adjust the yeast solution to pH = 6.0; separate with a laminated separator, collect the separated heavy phase, then add water to the obtained heavy phase, the amount of water added is the same as the volume of the obtained heavy phase, and stir After 30 minutes, the separator was used for separation, and the resulting heavy phase was drum-dried to obtain low-nucleic acid yeast sample 2 # .

Embodiment 3

[0031] Take the yeast for Angel noodles produced by Angel Yeast Co., Ltd., add deionized water, and prepare a solution with a mass percentage concentration of 5%; adjust the yeast solution to pH=6.0 with sulfuric acid and sodium hydroxide; then, the The yeast solution was incubated at 60°C for 1 hour; then the yeast solution was adjusted to pH=7.0; the separated heavy phase was collected with a laminated separator, and then water was added to the heavy phase obtained, the amount of water added was the same as the volume of the heavy phase obtained, After stirring for 30 minutes, separate with a separator, and spray-dry the resulting heavy phase to obtain a low-nucleic acid yeast sample 1 # .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com