Thermal insulating treatment process of external wall and thermal insulating external wall

A technology for thermal insulation of exterior walls and walls, which is applied in thermal insulation, building thermal insulation materials, and processing of building materials. It can solve problems such as poor thermal insulation effects of walls, and achieve improved living comfort, improved fire performance, and good sound insulation effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

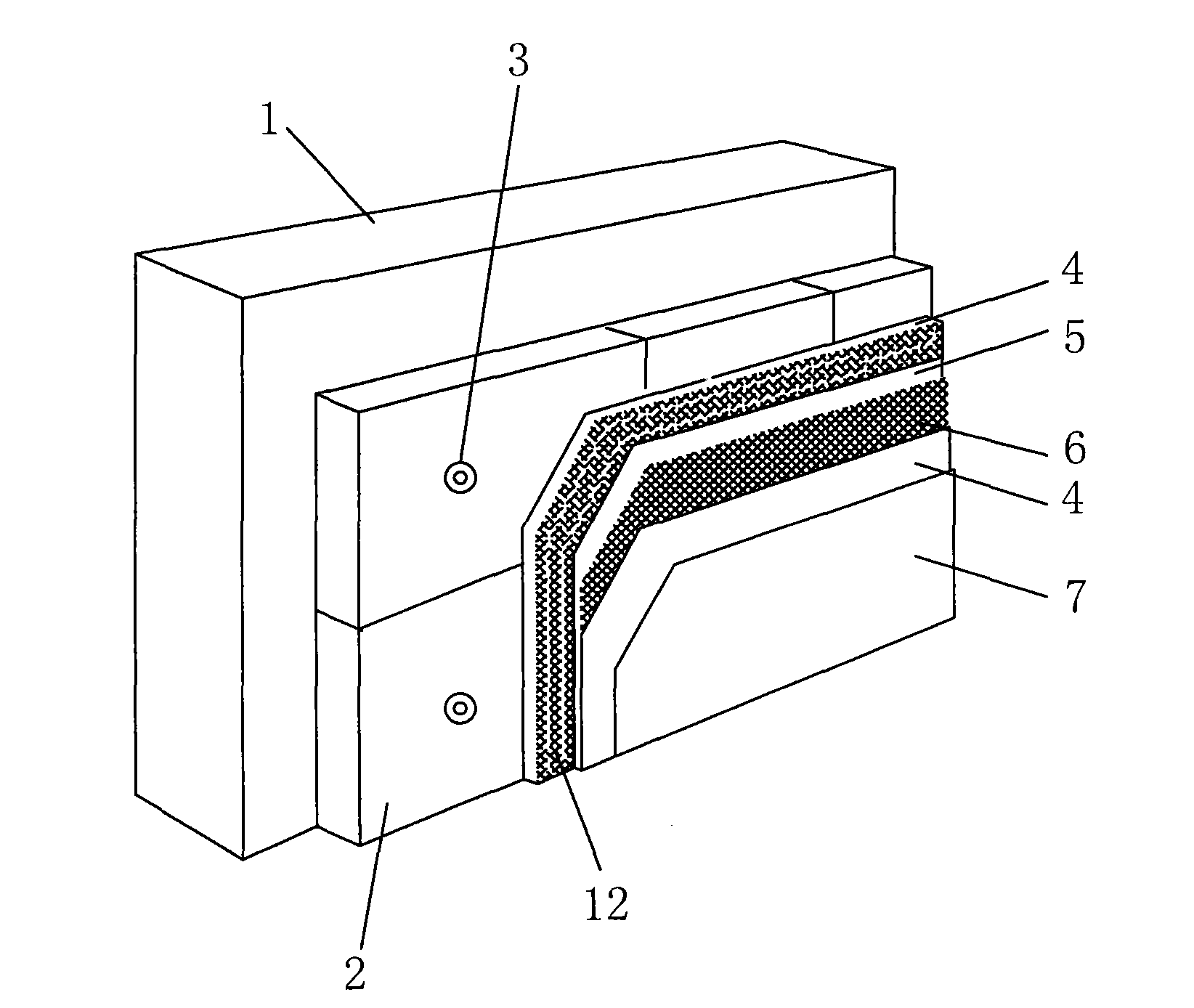

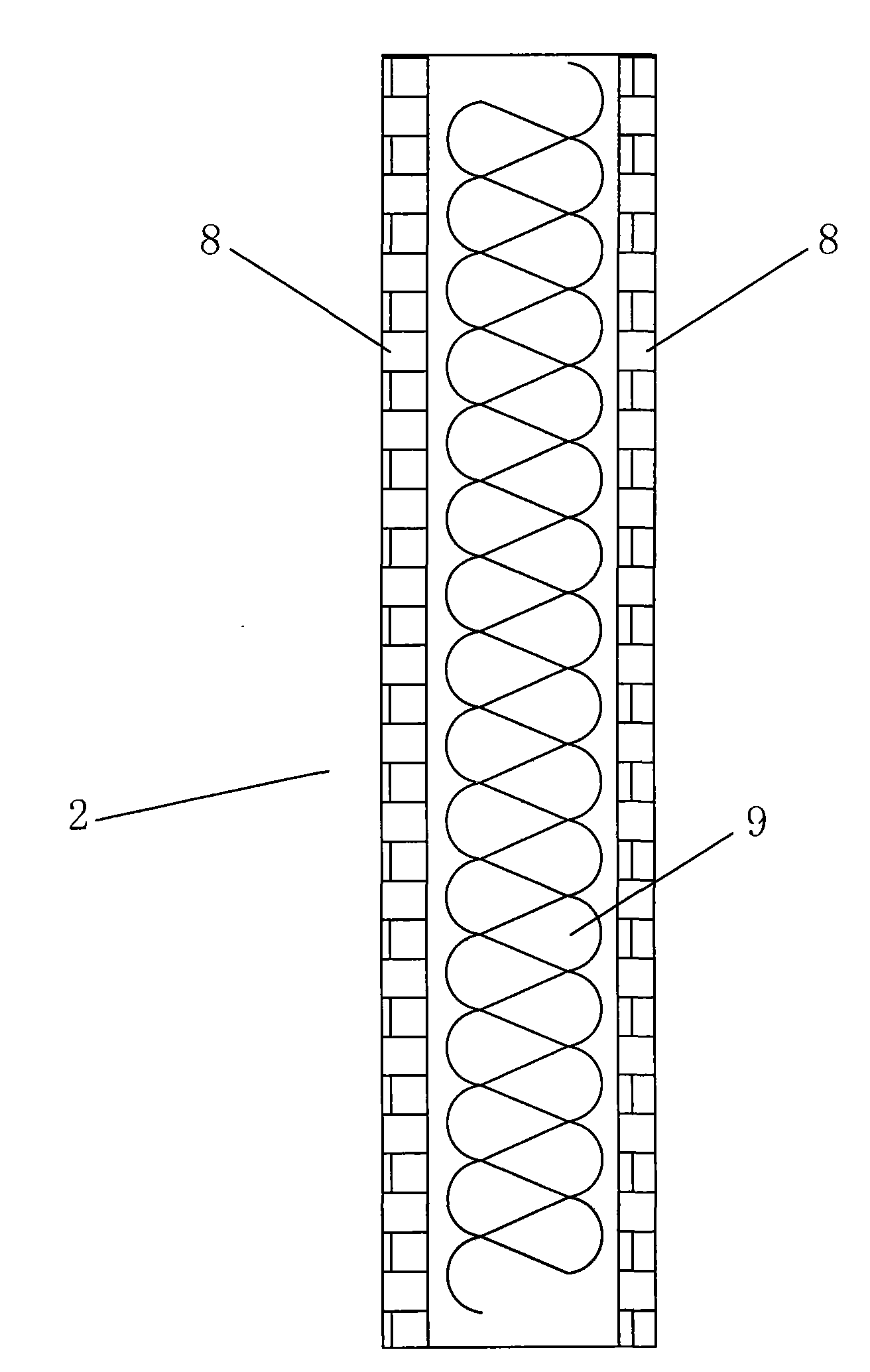

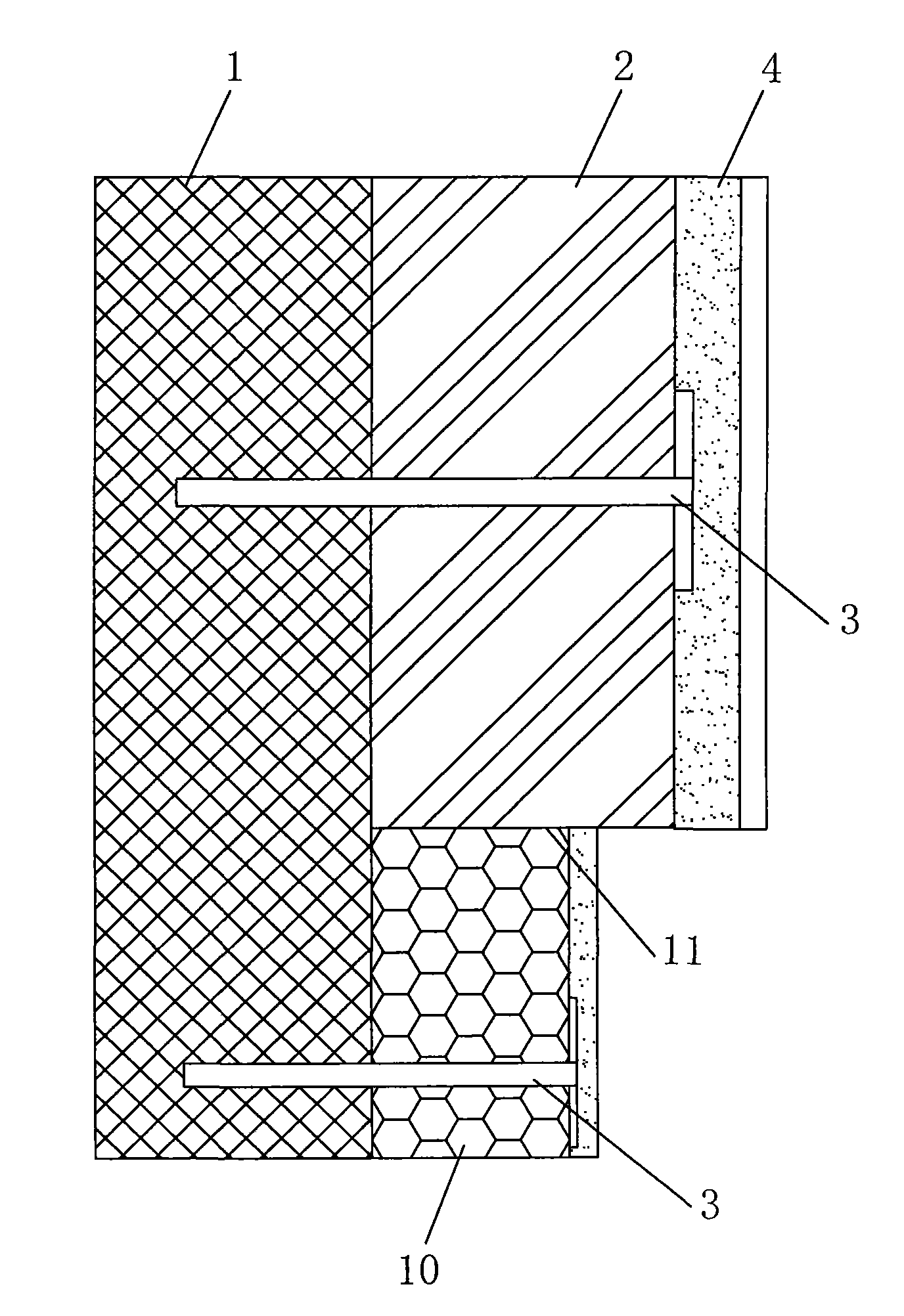

[0021] Because the present invention adopts the composite board of cement wood wool and mineral wool, it provides additional sound insulation function for the wall, and further improves the living quality of the living room. The cement wood wool and mineral wool composite board 2 includes two surface layers and a core layer, the surface layer is a cement wood wool board 8, and the core layer has a bulk density of 120Kg / m 3 -150Kg / m 3 The thickness of the surface layer is 5mm-15mm; the thickness of the core layer is 25mm-100mm, and the surface layer of the cement wood wool and mineral wool composite board 2 can be determined according to different regions, different temperatures and humidity and core thickness. In addition, the biggest feature is that it has air permeability and breathing performance, which can quickly evaporate the internal moisture to the external space. Because in most cases, it can be installed systematically without cleaning the existing outer layer of p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com