Gasoline engine with eccentric rotor

A gasoline engine and eccentric rotor technology, which is applied to combustion engines, machines/engines, internal combustion piston engines, etc., can solve the problems that triangular rotor engines have not been popularized and used, cannot be made into high-power engines, and triangular rotors have complex structures, etc., to overcome The effect of low thermodynamic efficiency, increased quantity, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

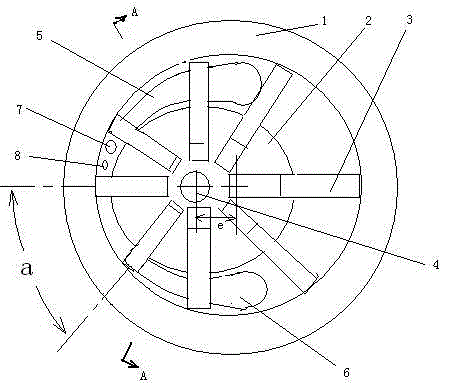

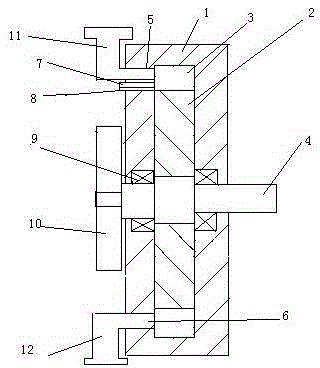

[0016] Such as figure 1 and figure 2 As shown, an eccentric rotor gasoline engine of the present invention includes a stator 1 with a circular cross-section in the inner cavity, a rotor 2 with a circular cross-section in the inner cavity of the stator 1, and an opening and closing control mechanism. The air hole 5, the exhaust hole 6, and the gasoline nozzle 7, the axis of the rotor 2 is parallel to the axis of the stator 1, and the distance between the axis of the rotor 2 and the axis of the stator 1 to the left in the horizontal direction is e (setter 1 The diameter of the inner cavity is D, the diameter of the rotor 2 is d, then 0figure 1 The output shaft 4 is provided with a flywheel 10 for counterweight and rotation balance; 8 through slots are evenly distributed along the circumferential direction on the circumference of the rotor 2, and the through slots are arranged along the shaft Parallel to the axis of the rotor 2, a rectangular vane 3 is provided in each of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com